With the Safety Modernization Act FSMA 204 compliance deadline approaching in January 2026, food manufacturers face unprecedented pressure to implement comprehensive traceability systems. Food recalls cost companies an average of $10 million in direct costs alone, not including the devastating impact on brand reputation and consumer trust. However, the right food traceability software can reduce these risks by up to 80% while streamlining operations and ensuring regulatory compliance.

The global food safety initiative has elevated traceability from a best practice to a legal requirement, transforming how food companies track raw materials through their entire supply chain. Modern traceability solutions leverage cutting-edge technology to provide end to end traceability, giving food businesses the visibility and control they need to protect consumers and their bottom line.

Key Takeaways

- Food traceability software tracks products from farm to fork, enabling rapid response to safety issues and ensuring FSMA 204 compliance by January 2026

- Modern traceability systems reduce recall costs by up to 80% through precise batch tracking and automated critical tracking events (CTE) documentation

- Integration capabilities with ERP systems and supply chain management platforms streamline operations for food manufacturers of all sizes

- Real-time monitoring and automated alerts prevent foodborne illness outbreaks by identifying contamination sources within minutes instead of days

- Cloud-based traceability solutions starting at $50/month make advanced tracking accessible to small food producers and large enterprises alike

- Automating data collection reduces manual errors, streamlines audits, and improves regulatory compliance

Table of Contents

- What is Food Traceability Software?

- Essential Benefits of Food Traceability Software

- Key Features to Look for in Food Traceability Software

- Implementation Considerations for Food Manufacturers

- Choosing the Right Food Traceability Software

- Future Trends in Food Traceability Technology

- Best Practices for Food Traceability

- Common Challenges and Solutions

- Employee Training and Support

- System Maintenance and Updates

- Customer Support and Service

- Frequently Asked Questions

- Build a Safer, Smarter Food Supply Chain

What is Food Traceability Software?

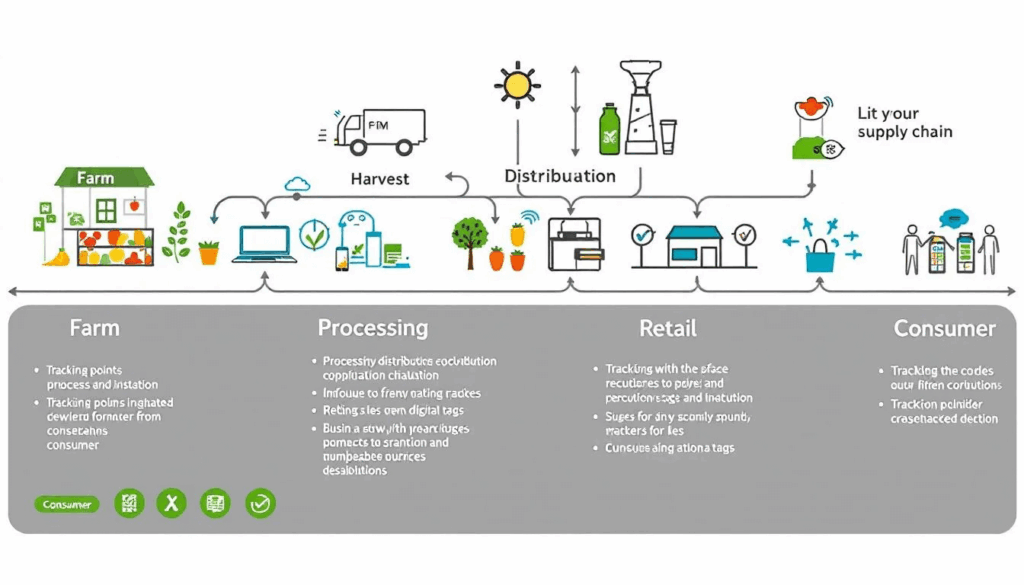

Food traceability software is a comprehensive digital system that tracks and documents the complete journey of food products from raw materials through production, processing, and distribution. Unlike manual paper-based systems that plagued the food industry for decades, modern traceability technology creates an unbroken digital chain of custody that enables food manufacturers to trace any ingredient or finished product within minutes rather than days.

The system captures critical tracking events (CTE) required by FSMA 204 Final Rule taking effect January 20, 2026. These events include receiving raw materials, transforming ingredients during production processes, creating new lot codes, and shipping finished products to distributors or retailers. Every touchpoint generates data that becomes part of an immutable record, ensuring complete visibility across global supply chains.

Modern food traceability systems maintain comprehensive audit trails linking ingredient suppliers, production batches, and final distribution channels. Batch management features play a crucial role by helping track raw materials, ensure consistency in production, and facilitate rapid recalls when necessary, supporting compliance with food safety regulations. When a food safety issue arises, operators can instantly access detailed information about every component that went into affected products, where those components originated, and exactly which customers received potentially contaminated products.

The best food traceability software provides immediate access to product history data during food safety inspections and recall situations. Rather than scrambling through paper records or multiple disconnected systems, quality managers can generate complete batch reports within minutes, demonstrating compliance with food safety regulations and minimizing disruption to operations.

Integration capabilities with existing food safety management systems including HACCP, SQF, and BRC protocols ensure that traceability data seamlessly flows into broader food safety compliance frameworks. This integration eliminates duplicate data entry and ensures consistency across all safety protocols, making it easier for food companies to maintain their certifications and pass audits.

Essential Benefits of Food Traceability Software

Enhanced Food Safety and Quality Control

Real-time contamination detection represents one of the most critical advantages of modern traceability solutions. By continuously monitoring production processes and automatically flagging deviations from established safety parameters, these systems can identify potential food safety risks before products reach consumers, significantly reducing the likelihood of foodborne illnesses.

Automated temperature monitoring prevents cold chain breaks that cause spoilage in dairy, meat, and frozen food products. IoT sensors integrated with traceability platforms continuously track storage and transportation conditions, immediately alerting operators when temperatures exceed safe ranges. This real time monitoring capability has proven invaluable for food producers handling temperature-sensitive products where even brief exposure to improper conditions can compromise safety and quality.

Allergen tracking capabilities prevent cross-contamination incidents that affect consumers with food allergies. The software maintains detailed records of which production lines handled allergenic ingredients, when equipment was cleaned between runs, and how ingredients were segregated throughout the production process. Food technologists play a key role in establishing these standards and ensuring compliance with food safety regulations. This level of detail enables food manufacturers to provide accurate labeling and respond quickly to allergen-related inquiries from consumers and regulators.

Shelf-life management functionality automatically flags products approaching expiration dates to prevent spoiled inventory distribution. The system tracks production dates, processes applied, and expected shelf life for every batch, providing early warnings when products risk exceeding their safe consumption window. This proactive approach minimizes waste while protecting consumer safety and brand reputation.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Regulatory Compliance and Risk Management

FSMA 204 compliance through automated documentation of critical tracking events represents a fundamental shift in how food companies manage regulatory requirements. The new regulations specifically target high-risk foods like leafy greens, cheeses, and nut butters, requiring detailed records that many companies struggle to maintain manually. Traceability software automates this documentation process, ensuring consistent compliance across all covered products.

HACCP integration maintains hazard analysis records and corrective action documentation within a single platform. When critical control points are exceeded or corrective actions are required, the system automatically generates the detailed records required for regulatory compliance. This integration ensures that food safety efforts remain coordinated and that no critical data falls through the cracks during busy production periods.

Organic certification support tracks certified organic ingredients through production to maintain USDA Organic status. The software segregates organic and conventional ingredients, maintains chain of custody documentation, and prevents commingling that could jeopardize organic certification. Ethical sourcing practices are also increasingly important for regulatory compliance and building consumer trust, as they enhance supply chain transparency and demonstrate a commitment to responsible sourcing. For food businesses producing organic products, this capability is essential for maintaining premium pricing and market access.

Export documentation generation for international markets requiring certificates of origin and food safety attestations streamlines global trade operations. The system can instantly generate the detailed documentation required by importing countries, reducing delays and ensuring compliance with diverse international food safety standards.

Rapid Recall Management

Modern recall management capabilities enable food companies to pinpoint contaminated batches within 2-4 hours instead of traditional 2-3 day investigation periods. When contamination is suspected, the software instantly identifies all affected batches, their current locations, and the specific customers who received potentially compromised products. This speed is crucial for minimizing health risks and reducing financial impact.

Automated notification systems alert distributors and retailers about affected products immediately upon recall initiation. Rather than manually contacting dozens or hundreds of customers, the system sends standardized notifications with detailed product information, lot numbers, and specific actions required. This automation ensures consistent messaging and reduces the time required to remove dangerous products from commerce.

Cost reduction through precise batch targeting removes only affected products instead of entire product lines. Traditional recalls often involved removing broad categories of products when companies couldn’t quickly identify specific affected batches. With precise traceability data, companies can limit recalls to only those products actually at risk, dramatically reducing financial losses and waste.

Consumer protection through rapid removal of compromised food products from retail shelves represents the ultimate goal of any recall program. The combination of rapid identification, automated notifications, and precise targeting enables food companies to protect public health while minimizing unnecessary disruption to safe products and normal business operations.

Supply Chain Transparency and Optimization

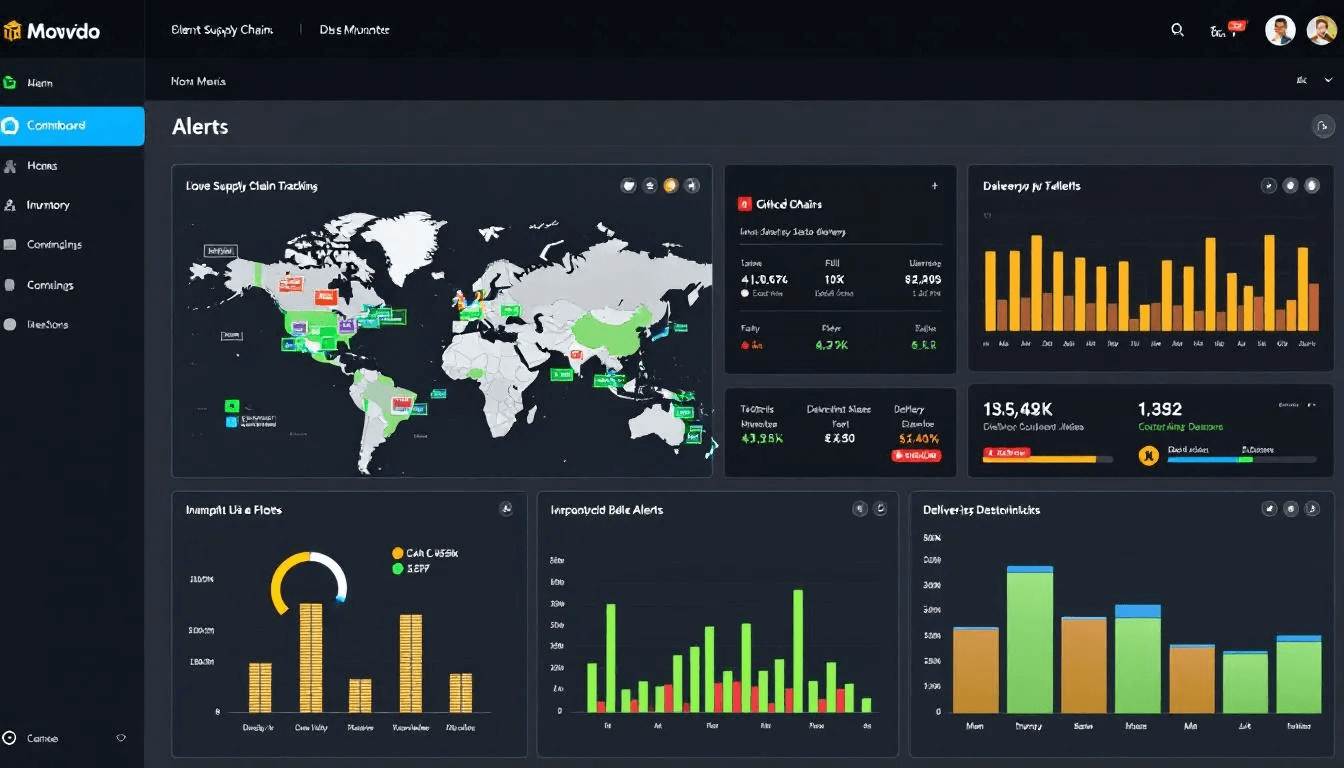

End-to-end visibility from farm suppliers through processing facilities to retail distribution centers creates unprecedented insight into food supply chains. Modern global supply chains involve dozens of suppliers, multiple processing steps, and complex distribution networks. Traceability software maps these relationships and provides real-time visibility into the status and location of ingredients and products throughout the entire supply chain. With this technology, companies can track products at every stage of the supply chain, ensuring transparency and compliance.

Supplier verification tracking ensures all vendors meet food safety certification requirements. The system maintains current certification records for every supplier, automatically alerts when certifications approach expiration, and flags any suppliers with outstanding compliance issues. This proactive supplier compliance monitoring protects food companies from using non-compliant ingredients that could jeopardize their own certifications.

Inventory optimization reduces waste by tracking ingredient freshness and production scheduling. The system provides real-time visibility into ingredient ages, enabling production planners to use older inventory first and optimize batch sizes to minimize waste. For food manufacturers dealing with perishable ingredients, this optimization can significantly reduce costs while maintaining product quality.

Blockchain integration provides immutable records for premium products requiring authenticity verification. For high-value products like organic foods, specialty cheeses, or premium seafood, blockchain technology creates tamper-proof records that guarantee authenticity from source to consumer. This capability is increasingly important for brands competing on quality and authenticity claims.

Key Features to Look for in Food Traceability Software

Core Tracking Capabilities

Lot and batch tracking with unique identifiers linking raw materials to finished products forms the foundation of any effective traceability system. Every incoming ingredient receives a unique identifier that follows it through processing, transformation, and incorporation into finished products. This creates an unbroken chain of custody that enables precise tracking in both directions – from finished products back to original sources or from raw materials forward to all derived products. Modern food traceability tools offer user-friendly interfaces and often provide free trials or demos, allowing companies to evaluate their effectiveness in ensuring food safety and improving supply chain transparency.

Barcode and QR code scanning for automated data capture during receiving, production, and shipping eliminates manual data entry errors while accelerating data collection. Workers scan codes at each process step, automatically updating the system with accurate time stamps, locations, and process information. This automation is crucial for maintaining data accuracy in fast-paced production environments where manual recording is error-prone and time-consuming.

Recipe and bill of materials (BOM) tracking shows exact ingredient quantities in each production run. The system maintains detailed records of which specific ingredient batches were used in each finished product batch, including exact quantities and any substitutions made during production. This granular level of detail is essential for accurate allergen labeling, nutritional analysis, and recall precision.

Forward and backward traceability enabling tracking both upstream to suppliers and downstream to customers provides complete supply chain visibility. When issues arise, operators can immediately identify the source of problematic ingredients (backward traceability) and all products and customers potentially affected (forward traceability). This bidirectional capability is essential for rapid response to food safety incidents.

Integration and Connectivity

ERP system integration with SAP, Oracle, QuickBooks, and NetSuite ensures seamless financial data flow and eliminates duplicate data entry. Modern food manufacturers rely on integrated business systems, and traceability software must work within these existing frameworks. Proper integration synchronizes inventory data, purchase orders, production schedules, and financial transactions across all systems.

API connectivity enabling custom integrations with existing warehouse management systems provides flexibility for companies with specialized operational requirements. Well-designed APIs allow traceability systems to connect with legacy equipment, specialized production machinery, and industry-specific software packages that may not offer standard integration options.

EDI capabilities for automated data exchange with major retailers like Walmart, Target, and Kroger streamline customer reporting requirements. Large retailers increasingly demand detailed traceability data from suppliers, and EDI integration automates this reporting process. This capability is essential for food manufacturers selling to major retail chains that require electronic data interchange for supply chain management.

Mobile app support for production floor workers enables data input using tablets and smartphones. Production environments often require mobility and durability that traditional desktop systems cannot provide. Mobile applications allow workers to scan barcodes, record observations, and access critical information while moving through production facilities.

Reporting and Analytics

Automated compliance reports for FDA inspections, customer audits, and certification renewals eliminate the time-consuming process of manually compiling regulatory documentation. The system maintains all required records in formats that match regulatory requirements and can instantly generate comprehensive reports for any time period or product category.

Real-time dashboard showing production status, inventory levels, and quality metrics provides management with immediate visibility into operations. These dashboards typically display key performance indicators, alert summaries, and trend analysis that enable proactive decision-making rather than reactive problem-solving.

Cost analysis tools tracking ingredient costs, labor efficiency, and production waste help optimize operations beyond basic traceability requirements. By analyzing patterns in ingredient usage, production yields, and waste generation, food manufacturers can identify opportunities for cost reduction and efficiency improvements.

Predictive analytics identifying potential supply chain disruptions and quality issues represents the cutting edge of traceability technology. Advanced systems use machine learning algorithms to analyze historical data and identify patterns that precede problems, enabling preventive action rather than reactive responses.

Implementation Considerations for Food Manufacturers

Business Size and Complexity

Small producers with revenue under $5 million typically benefit most from cloud-based solutions with monthly subscription pricing starting at $50-200. These companies often lack dedicated IT staff and prefer solutions that require minimal infrastructure investment. Cloud-based traceability software provides enterprise-level capabilities without the complexity and cost of traditional enterprise software implementations.

Medium manufacturers with revenue between $5-50 million require multi-location support and advanced integration capabilities, typically costing $500-2000 monthly. These companies often operate multiple facilities, work with diverse supplier networks, and sell to various customer types. Their traceability needs are more complex but still benefit from standardized solutions rather than custom development.

Large enterprises with revenue over $50 million need custom implementations with dedicated servers and extensive customization. These companies typically have unique operational requirements, complex regulatory obligations, and integrate traceability with broader enterprise resource planning systems. Implementation costs can reach tens of thousands of dollars, but the scale of operations justifies this investment.

Multi-site operations require centralized data management with location-specific access controls and reporting. Companies operating multiple facilities need unified visibility across all locations while maintaining appropriate security controls. The system must support different user roles, local reporting requirements, and facility-specific operational procedures.

Industry-Specific Requirements

Meat and poultry processors need FSIS compliance features and SSOP (Sanitation Standard Operating Procedures) documentation. These facilities operate under some of the strictest food safety regulations and require specialized features for temperature monitoring, pathogen testing results, and detailed sanitation records. The software must integrate with FSIS-required systems and support the unique labeling and inspection requirements of meat processing.

Food manufacturing processes benefit from traceability software by ensuring food safety, regulatory compliance, and supply chain transparency.

Dairy manufacturers require pasteurization temperature logs and milk supply chain tracking from farm to retail. Dairy products face unique safety challenges related to temperature control, bacterial contamination, and shelf life management. Traceability systems must support continuous temperature monitoring, integration with pasteurization equipment, and detailed farm-level tracking for milk sourcing.

Beverage companies need ingredient sourcing verification and alcohol content tracking for regulatory compliance. Beverage production involves complex blending processes, multiple ingredient sources, and strict labeling requirements. For alcoholic beverages, additional TTB (Tobacco Tax and Trade Bureau) compliance features are essential.

Organic food producers require certified organic ingredient tracking and segregation documentation. Maintaining organic certification requires detailed documentation proving that organic and conventional ingredients never commingle and that all ingredients meet organic standards. The software must support parallel tracking systems and generate the detailed audit trails required for organic certification maintenance.

Technology Infrastructure

Cloud-based deployment offers faster implementation (2-8 weeks) and lower upfront costs, making it attractive for companies wanting rapid deployment. Cloud solutions eliminate the need for server hardware, reduce IT support requirements, and provide automatic software updates. However, companies must evaluate data security, internet connectivity requirements, and ongoing subscription costs.

On-premise installations provide greater data control but require IT infrastructure investment. Companies with sensitive data requirements, limited internet connectivity, or strict data sovereignty requirements may prefer on-premise deployment. This approach requires dedicated server hardware, IT support staff, and more complex implementation processes.

Hybrid solutions combine cloud accessibility with local data storage for sensitive information. This approach provides the flexibility of cloud access while maintaining control over critical data. Hybrid deployments are often chosen by companies that need cloud benefits but have regulatory or security requirements that limit full cloud adoption.

Mobile device compatibility ensures production floor workers can access and input data efficiently. Modern traceability systems must support tablets, smartphones, and industrial-grade mobile devices used in food production environments. The mobile interface should be optimized for use with gloves, in varying lighting conditions, and in environments where devices may be exposed to moisture or temperature extremes.

Choosing the Right Food Traceability Software

Evaluation Criteria

Regulatory compliance support for applicable standards (FSMA, HACCP, SQF, BRC, IFS) represents the foundation of any food traceability system evaluation. The software must support all current regulatory requirements relevant to your operation and provide a clear upgrade path for future regulatory changes. Verify that the system can generate all required reports and maintain all necessary records in formats acceptable to regulatory agencies.

Scalability to accommodate business growth and additional production facilities ensures that your investment will continue providing value as your company expands. Evaluate how the system handles increased transaction volumes, additional users, new product lines, and expanded geographical operations. The best traceability software grows with your business rather than requiring replacement as you expand.

User interface design ensuring easy adoption by production workers with varying technical skills directly impacts implementation success. The system must be intuitive enough for workers to use effectively with minimal training while providing the detailed functionality required for comprehensive traceability. Consider conducting user testing with actual production workers during the evaluation process.

Vendor support quality including implementation assistance, training programs, and ongoing technical support determines long-term success. Evaluate the vendor’s implementation methodology, training resources, technical support availability, and customer satisfaction ratings. The complexity of traceability systems makes vendor support quality crucial for successful deployment and ongoing operations.

Speed Up Your Warehouse Operations

A Simple Guide: How to Label Your Warehouse Bin Locations

Cost Considerations

Subscription pricing typically ranges from $50/month for basic systems to $5000+/month for enterprise solutions, depending on the number of users, features required, and integration complexity. Basic systems suitable for small food producers with simple operations start at the low end, while comprehensive enterprise solutions supporting multiple facilities and complex supply chains command premium pricing.

Implementation costs including data migration, training, and system customization often equal 6-12 months of subscription fees. These one-time costs cover initial system setup, data migration from existing systems, staff training, and any required customizations. Properly budgeting for implementation costs prevents surprises and ensures adequate resources for successful deployment.

ROI calculation should include reduced recall costs, improved operational efficiency, and avoided compliance penalties. While software costs are easily quantified, benefits often extend beyond obvious savings. Consider the value of improved efficiency, reduced manual labor, faster recall response, and avoided regulatory penalties when evaluating the return on investment.

Total cost of ownership includes ongoing training, system updates, and potential integration maintenance. Beyond subscription and implementation costs, factor in ongoing expenses for new user training, system maintenance, integration updates, and potential feature additions. Understanding the complete cost picture enables better long-term planning and budgeting.

Vendor Selection Process

Request demonstrations using your actual production data and workflow scenarios rather than generic presentations. Realistic demonstrations reveal how well the software handles your specific operational requirements and integration needs. Prepare sample data and workflow scenarios that reflect your actual operations to ensure the demonstration provides meaningful insights.

Evaluate customer references from similar-sized companies in your specific food sector. References from companies with similar operations, regulatory requirements, and operational scale provide the most relevant insights. Ask specific questions about implementation challenges, ongoing support quality, and actual benefits achieved.

Test system performance during peak production periods to ensure adequate response times. Traceability systems must perform reliably during busy production periods when rapid data entry and retrieval are critical. Request performance testing or trial periods that include peak operational scenarios.

Review security certifications including SOC 2 compliance and data encryption protocols. Food traceability data includes sensitive business information and potentially personally identifiable information. Verify that the vendor maintains appropriate security certifications and follows industry best practices for data protection.

Future Trends in Food Traceability Technology

Emerging Technologies

Artificial intelligence and machine learning algorithms are revolutionizing how food companies predict quality issues and optimize production schedules. These technologies analyze vast amounts of traceability data to identify patterns that humans might miss, enabling predictive maintenance, quality optimization, and supply chain risk mitigation. AI-powered systems can predict when equipment needs maintenance based on production patterns, identify ingredients likely to cause quality issues, and optimize production scheduling to minimize waste.

Internet of Things (IoT) sensors provide continuous monitoring of temperature, humidity, and other environmental factors throughout the entire supply chain. These sensors automatically feed data into traceability systems, creating unprecedented visibility into storage and transportation conditions. For food products requiring strict environmental controls, IoT integration ensures that any deviations are immediately detected and documented.

Blockchain technology creates tamper-proof records for premium and organic food products requiring authenticity verification. While still emerging, blockchain adoption is accelerating among food companies seeking to differentiate their products through verified authenticity claims. Major retailers like Walmart are piloting blockchain systems for high-value products, and this technology is expected to become more mainstream as implementation costs decrease.

Digital twins modeling entire supply chains enable companies to simulate disruption scenarios and optimize responses. These virtual models of actual supply chains allow food companies to test different scenarios, identify vulnerabilities, and develop contingency plans without disrupting actual operations. Digital twin technology is particularly valuable for complex global supply chains where disruptions can have cascading effects.

Regulatory Evolution

FSMA 204 implementation deadline of January 20, 2026 is driving unprecedented adoption of digital traceability systems across the food industry. Companies that have delayed traceability investments are now scrambling to achieve compliance, creating significant demand for implementation services and software solutions. This regulatory deadline represents the largest single driver of traceability technology adoption in the food industry’s history.

European Union regulatory changes requiring enhanced traceability for imported food products starting in 2025 are expanding compliance requirements for food companies serving global markets. These regulations will require detailed documentation for food products entering EU markets, regardless of where they were produced. Food companies exporting to Europe must ensure their traceability systems meet these enhanced requirements.

State-level requirements like California’s food traceability laws are creating additional compliance needs beyond federal regulations. As states implement their own traceability requirements, food companies must navigate an increasingly complex regulatory landscape. Traceability systems must be flexible enough to accommodate varying state requirements while maintaining federal compliance.

International harmonization efforts are working to standardize traceability data formats for global food trade. Organizations like the Global Food Safety Initiative are developing common standards that will simplify compliance for companies operating in multiple markets. These standardization efforts will likely accelerate adoption of compatible traceability systems.

The convergence of regulatory pressure, technological advancement, and consumer demand for transparency is fundamentally transforming the food industry. Companies that embrace comprehensive traceability systems today will be better positioned to navigate future regulatory changes, respond to consumer demands, and protect their brands from food safety incidents.

As the January 2026 FSMA 204 deadline approaches, food manufacturers can no longer afford to delay traceability implementation. The best food traceability software solutions provide immediate benefits through improved operational efficiency, reduced compliance costs, and enhanced food safety capabilities while positioning companies for long-term success in an increasingly regulated and transparent marketplace.

The investment in modern traceability technology pays dividends through reduced recall costs, improved supplier compliance, enhanced consumer trust, and streamlined regulatory compliance. Food companies that act now to implement comprehensive traceability solutions will not only achieve FSMA 204 compliance but will also gain competitive advantages through improved supply chain transparency and operational efficiency.

Start evaluating traceability solutions today to ensure your food business is prepared for the regulatory requirements and market demands of 2026 and beyond. The companies that move quickly to implement robust traceability systems will be best positioned to thrive in the new regulatory environment while protecting their customers and their brands.

Best Practices for Food Traceability

Implementing effective food traceability software is essential for food manufacturers aiming to meet the rigorous demands of food safety regulations, including the Food Safety Modernization Act (FSMA). To ensure compliance and maximize the benefits of traceability, food companies should prioritize maintaining accurate, detailed records at every stage—from sourcing raw materials to managing production processes and tracking products throughout the supply chain. This level of documentation enables rapid identification and response to food safety issues, minimizing risks to consumers and safeguarding brand reputation.

Regular audits and assessments of the traceability system are crucial for verifying that all processes remain compliant with current regulatory requirements. Food businesses should establish clear protocols for data entry, record retention, and system updates to ensure the traceability software remains effective as operations evolve. By fostering a culture of food safety and continuous improvement, manufacturers can enhance overall operational efficiency, reduce the likelihood of costly recalls, and build lasting consumer trust. Ultimately, investing in robust traceability systems and adhering to best practices positions food manufacturers to stay compliant, minimize risks, and thrive in a competitive marketplace.

Common Challenges and Solutions

Food manufacturers often encounter several challenges when implementing and maintaining food traceability systems. Managing large volumes of data, navigating complex supply chains, and keeping up with evolving food safety regulations can be daunting. These challenges can hinder supply chain visibility and make it difficult to ensure consistent regulatory compliance.

To address these issues, food businesses should invest in user-friendly traceability software that automates data collection and streamlines analysis. Choosing solutions that integrate seamlessly with existing systems can help reduce manual errors and improve data accuracy. Collaboration with suppliers and partners is also key—establishing clear data-sharing protocols ensures that traceability information flows smoothly across the entire supply chain.

Ongoing employee training and support are vital for maintaining high food safety standards and ensuring compliance. By fostering a proactive approach to regulatory changes and leveraging advanced traceability solutions, food manufacturers can enhance supply chain visibility, reduce the risk of recalls, and maintain a strong reputation for food safety. Ultimately, overcoming these challenges enables food businesses to meet safety standards and regulatory requirements with confidence.

Employee Training and Support

A successful food traceability system relies heavily on well-trained employees who understand both the technology and the importance of food safety. Food manufacturers should provide comprehensive training on the use of traceability software, ensuring that staff are comfortable with data entry procedures and understand how their actions impact supply chain transparency and consumer safety.

Regular training sessions should cover updates to regulatory requirements, such as those introduced by the FSMA, as well as best practices for maintaining accurate records and minimizing human error. Encouraging employees to report any issues or concerns with the traceability system helps identify potential problems early and supports continuous improvement.

By investing in ongoing employee training and support, food businesses can maximize the effectiveness of their traceability system, enhance supply chain transparency, and ensure compliance with food safety regulations. This commitment not only reduces the risk of errors but also strengthens consumer trust in the safety and integrity of their products.

System Maintenance and Updates

Maintaining the effectiveness and compliance of food traceability software requires regular system maintenance and timely updates. Food manufacturers should work closely with their software providers to stay informed about new features, security patches, and enhancements that can improve the performance and reliability of their traceability system.

Routine backups of traceability data are essential to prevent data loss and ensure business continuity in the event of a system failure. Periodic reviews of the traceability system help identify opportunities for improvement and ensure ongoing alignment with evolving regulatory requirements and industry standards.

By prioritizing system maintenance and updates, food businesses can protect their investment in traceability software, minimize operational disruptions, and continue to benefit from improved operational efficiency and enhanced food safety. Staying proactive in this area ensures that the traceability system remains a valuable tool for meeting both current and future compliance needs.

Customer Support and Services

Reliable customer support and service are critical for food manufacturers using food traceability software. A responsive software provider can quickly address technical issues, answer questions, and minimize disruptions to daily operations, ensuring that food safety efforts remain uninterrupted.

Comprehensive user guides and documentation should be readily available to help staff navigate the traceability system and resolve common issues independently. Additionally, a commitment to ongoing software development—incorporating customer feedback and adapting to regulatory changes—demonstrates that the provider is a true partner in achieving supply chain transparency and regulatory compliance.

By choosing a traceability software provider that prioritizes customer support and service, food manufacturers can confidently navigate the complexities of food safety regulations and supply chain management. This partnership is essential for maintaining a robust traceability system that supports both operational goals and long-term food safety objectives.

Frequently Asked Questions

What specific data must be captured under FSMA 204 that wasn’t required before?

FSMA 204 requires detailed critical tracking events (CTE) documentation for specific high-risk foods including exact location data, batch/lot codes, business names and addresses, and specific dates and times for key supply chain events. Unlike previous regulations that focused mainly on business-to-business recordkeeping, FSMA 204 requires granular tracking down to the retail level and mandates 24-hour response times for traceability requests. The rule also requires maintaining records for specific transformation events, such as when ingredients are combined into new products or when packaging changes occur.

How does traceability software handle multi-ingredient products with complex recipes?

Advanced traceability systems maintain detailed bill of materials (BOM) records that track every ingredient batch used in production, including exact quantities, substitutions, and processing conditions. Tracking raw material from purchase through production is essential for quality control and compliance, ensuring transparency and regulatory adherence throughout the food manufacturing process. The software creates unique identifiers for finished product batches while maintaining links to all component ingredients, enabling precise tracking even when dozens of ingredients are combined. Recipe management modules allow for real-time adjustments while maintaining traceability integrity, and the system can instantly identify which finished products are affected if any ingredient batch is recalled.

What cybersecurity measures should food companies consider when implementing cloud-based traceability systems?

Essential cybersecurity measures include SOC 2 Type II compliance, end-to-end data encryption both in transit and at rest, multi-factor authentication for all users, and regular security audits by third-party firms. Companies should also implement role-based access controls limiting user permissions to necessary functions, maintain secure backup systems with tested recovery procedures, and establish data governance policies covering retention, sharing, and deletion. Additionally, consider vendor security certifications, data residency requirements for international operations, and integration security when connecting with existing ERP or manufacturing systems.

Can small food producers afford comprehensive traceability software, or is it only practical for large companies?

Modern cloud-based traceability solutions have made comprehensive tracking accessible to small food producers with entry-level pricing starting around $50-200 per month. Many vendors offer scaled pricing based on transaction volume or number of users, making the technology economically viable even for small operations. Small producers can often achieve positive ROI within the first year through reduced manual recordkeeping costs, improved efficiency, and avoided compliance penalties. Some industry associations and government programs also offer grants or subsidized implementations to help small food businesses achieve FSMA 204 compliance.

Food service operations, especially those with multiple sites, also benefit from comprehensive traceability software for compliance and safety monitoring.

How long does traceability data need to be retained, and what happens to historical data if a company switches software providers?

FSMA 204 requires maintaining traceability records for at least two years, though many companies retain data longer for quality improvement and trend analysis purposes. When switching software providers, companies must ensure complete data migration including all historical batch records, supplier information, and audit trails to maintain regulatory compliance. Most reputable traceability software vendors provide data export tools and migration services, but companies should verify data portability before selecting a system and maintain backup copies of critical historical data during any transition period.

Build a Safer, Smarter Food Supply Chain

Mastering food traceability helps food manufacturers strengthen compliance, reduce recall risks, and improve transparency across every stage of production. With regulations tightening and customer expectations rising, investing in reliable tracking systems is no longer optional—it’s essential for long-term success.

Orders in Seconds supports food manufacturers and distributors with tools that simplify operations, connect teams, and improve visibility from inventory to delivery. When your systems work together, your entire supply chain runs smarter and safer. Learn more today with a free demo.