Mastering the reorder point formula is vital for avoiding stockouts and balancing stock levels. This guide simplifies the calculation, equipping you with the knowledge to make timely inventory decisions. Expect to gain insight into the components and practical application of the formula.

Key Takeaways

- The reorder point formula is essential for inventory management, signaling when to replenish stock based on key components such as demand rate, lead time, and safety stock to avoid stockouts and align with customer demand.

- Regular review and adjustment of reorder points are crucial to adapt to market and supply chain dynamics, with inventory management software providing automation and alerts to optimize stock levels and prevent stock shortages.

- Advanced techniques like Economic Order Quantity (EOQ) and Just-in-Time inventory management can further optimize inventory levels and reorder points, improving overall cost efficiency and reducing inventory-related expenses.

Table of Contents

- Understanding Reorder Point: The Basics

- Mastering the Reorder Point Formula

- Implementing Reorder Points in Your Business

- Overcoming Limitations and Challenges of Reorder Points

- Advanced Reorder Point Techniques

- Summary

- Frequently Asked Questions

- Going Beyond the Reorder Point: Empower Your Wholesale Distribution Business

Understanding Reorder Point: The Basics

The reorder point is the minimum stock level for an inventory item. When the stock reaches this point, new stock should be ordered to prevent a stockout. The purpose of a reorder point is to trigger the replenishment process to reorder items and maintain inventory levels capable of meeting customer demand.

Accurate reorder points guarantee punctual order fulfillment by circumventing stockouts during the waiting period for new inventory. Correctly calculating these points aids in preserving a competitive advantage and dodging inventory control problems. To achieve accurate reorder point calculations, having reliable data is crucial.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Key Components of Reorder Point

The reorder point formula is made up of vital elements such as:

Reorder point formula: (Average sales per day) x (Lead time in days) + Safety stock

- Average Sales per day: also known as "Demand Rate" is the rate at which customers are purchasing the product.

- Lead time: the time between placing a purchase order and receiving the product, influenced by supplier performance and supply chain analysis. To mitigate risks with new suppliers or unknown factors, lead time may be buffered to prevent inventory shortfall.

- Safety stock: extra inventory held to protect against unexpected fluctuations in demand or lead time.

These elements are used to calculate the reorder point, which is the inventory level at which a new order should be placed to replenish stock and avoid stockouts. The reorder quantity plays a crucial role in this process.

The demand rate, derived from average daily sales or usage, informs how much inventory is typically sold or used per day. Meanwhile, safety stock level is a crucial component that maintains adequate inventory during demand fluctuations or delayed supplies.

The Role of Safety Stock

Safety stock, a crucial part of preserving sufficient inventory levels, operates as a buffer, kept at the ready to account for possible variations in demand or supply. As such, it plays a critical role in inventory management, preventing stockouts and ensuring adequate inventory levels are maintained during demand or supply inconsistencies.

Proper management of safety stock levels is crucial; if safety stock is repeatedly used, it may indicate the need to increase replenishment orders or reevaluate safety stock levels. Thus, understanding the role of safety stock in the reorder point formula can significantly improve inventory management practices and enhance customer satisfaction.

Mastering the Reorder Point Formula

Acting as a fundamental tool in inventory management, the reorder point formula gives a signal when stock replenishment is needed. It consists of two primary components: average daily unit sales and delivery lead time. By using this formula, businesses can calculate the minimum amount of inventory needed to order more products and prevent stock depletions.

An essential component of this formula is the lead time demand, which represents the total quantity of a product consumed during its lead time. Safety stock is also added to the lead time demand to cater to unexpected demand surges and delays in delivery.

Calculating Lead Time Demand

While straightforward, the calculation of lead time demand is vital in setting reorder points. Average daily sales are calculated by dividing the total sales over a specific period by the total number of days in that period. To better understand the inventory needs, it’s also important to consider the average daily usage of the product.

The lead time demand calculation is obtained by multiplying the lead time for a product by its average daily sales. This figure represents the total quantity of a product that is consumed during its lead time and is a vital component in the calculation of reorder points.

Incorporating Safety Stock

The inclusion of safety stock in the reorder point formula is crucial for businesses to be ready for unforeseen spikes in demand and postponements in delivery. Basic safety stock is calculated by multiplying the average demand for items with a preset value of safety days.

Determining the safety stock involves the following steps:

Calculate the service level.

Factor in the standard deviation of lead time and average demand for the product.

Subtract the result from the product of average daily orders and average lead time to calculate the safety stock.

These elements are critical in managing inventory levels effectively.

Reorder Point Calculation Example

Let’s say you run a wholesale distribution business that sells food and beverage products. For this example, lets use a case of Coca-Cola and you sell four cases per day. You’ve determined that you always want to have a safety stock of 20 cases. And your supplier, needs a fair amount of lead time to fill an order: five weeks. What should your reorder point be?

Looking at the formula — (Average sales per day) x (lead time) + safety stock; you might calculate 4 x 5 + 20 and get 40. But remember, the average sales per day and lead time must be in the same units of days. If you’re selling four per day and need five weeks (i.e., 35 days, or 7 days for 5 weeks) for your order to arrive, you can expect to sell 4 x 35 = 140 cases while you’re waiting for your resupply. Putting everything in days, the calculation comes to:

Reorder Point = 4 × 35 + 20 = 160 cases of Coca-Cola

When your inventory is down to 160 cases, that’s when you need to order more from your supplier.

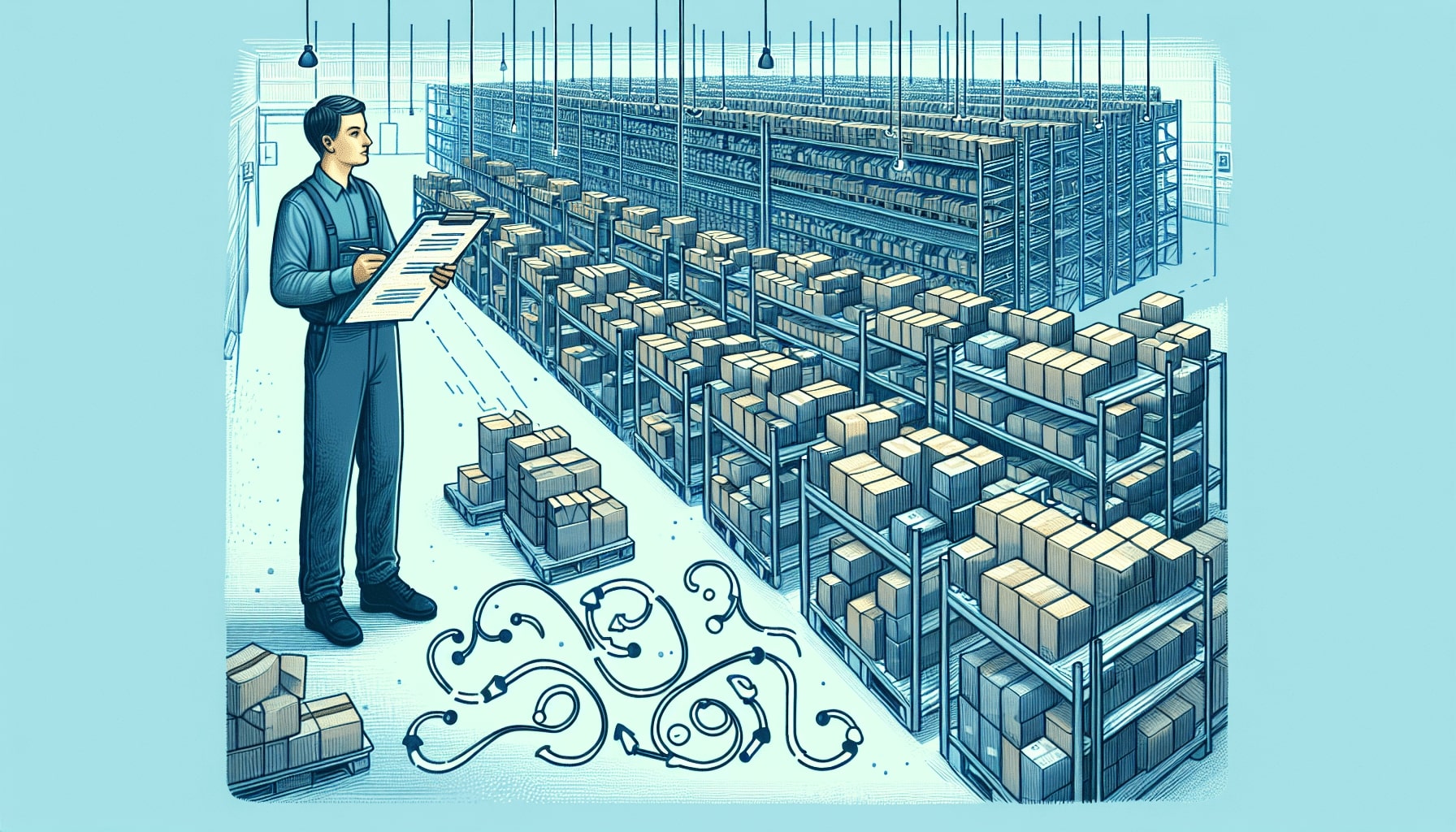

Implementing Reorder Points in Your Business

The application of reorder points in your enterprise can result in notable improvements in inventory management. An automated reorder point system triggers stock replenishment when inventory levels fall below a specific threshold, aligning with calculated reorder points. Automatic replenishment methods can improve efficiency by optimizing inventory levels and minimizing losses from overstocking or stockouts.

Implementing advanced reorder point strategies can involve considerations on:

- When to place orders in relation to approaching reorder points

- Factoring in higher demand on certain days

- Being practical about calendar-specific lead times

These strategies, coupled with regular reviews and adjustments, can greatly enhance the efficiency and effectiveness of your inventory management.

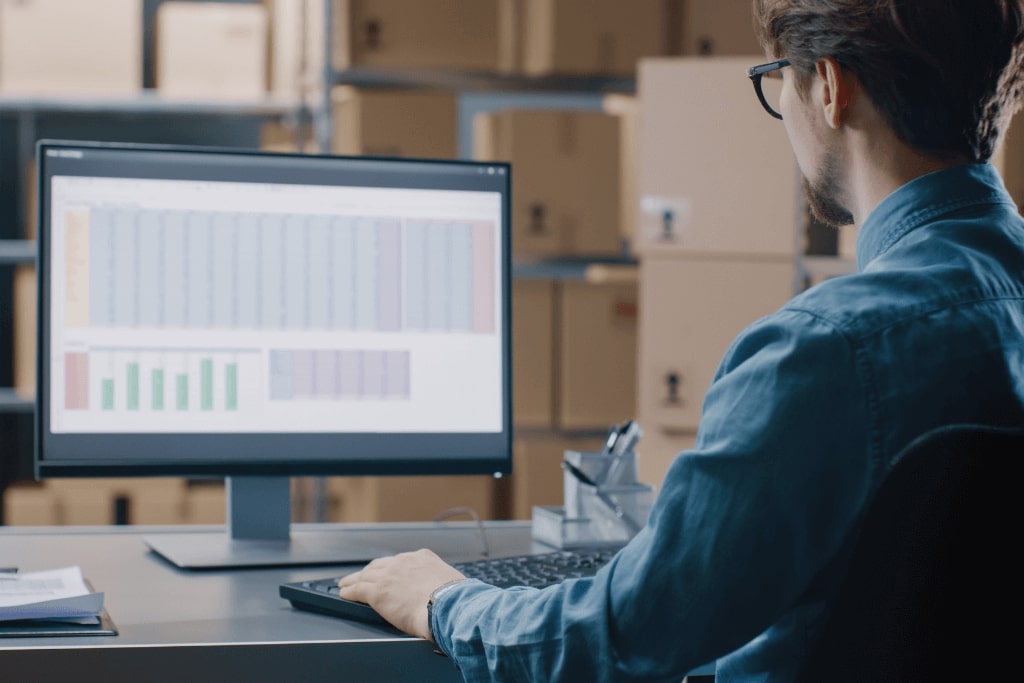

Choosing the Right Inventory Management Software

Selecting appropriate warehouse management software can offer substantial help in applying reorder points in your enterprise. Such software can alert businesses when they reach their reorder point to replenish stock, thus enhancing inventory control and preventing stockouts.

By automating reorder point calculations, inventory management software maintains constant monitoring of inventory levels, placing orders as necessary to sustain pre-defined stock quantities and improving accuracy. This level of automation and precision can significantly streamline the inventory management process, freeing up time and resources for other essential business operations

Regularly Reviewing and Adjusting Reorder Points

The necessity of regularly reviewing and adjusting reorder points is crucial for adapting to shifting market conditions and supply chain dynamics. Factors such as:

- marketing campaigns

- competitor activity

- community events

- changing seasonal demands

In order to maintain optimal inventory levels, it is crucial to calculate reorder points and require periodic revisions of them, ensuring the reorder point ROP is always accurate.

Businesses should consistently update their reorder points to adapt to changes in market demand, supply chain alterations, and other dynamic factors, including seasonalities and trends. Furthermore, reassessing reorder points at least quarterly ensures they align with current demand and supply chain conditions, thereby preventing stockouts and excess inventory.

Collaborating with Suppliers

Another significant aspect of applying reorder points in your enterprise is collaboration with suppliers. A collaborative relationship ensures timely product deliveries and provides accurate lead time information for reorder point calculations.

Sharing demand forecasts and purchase patterns with suppliers leads to more precise delivery schedules and optimal reorder points. Moreover, diversifying relationships with several suppliers helps mitigate the risk of inventory stockouts by factoring in varied supplier lead times when setting reorder points.

Thus, supplier collaboration plays a crucial role in effective inventory management and the successful implementation of reorder points.

Overcoming Limitations and Challenges of Reorder Points

Though reorder points serve as a potent instrument in inventory management, they carry their unique challenges and limitations. However, these can be overcome with advanced reorder point techniques and a comprehensive understanding of inventory management principles.

Hybrid models that merge the strengths of reorder points with demand forecasting are more adaptable to varying demand scenarios. Besides, the reliance on spreadsheets for reorder point calculations poses risks of errors due to potential incorrect formulas. But with the right strategies in place, these limitations can be effectively addressed.

Adapting to Seasonal Demand Fluctuations

A crucial strategy to overcome the limitations of reorder points is adaptation to seasonal demand fluctuations. Integrating demand forecasting methods that consider seasonality can improve reorder point accuracy during periods of seasonal demand fluctuations.

The use of software that utilizes historical data and forecasting allows for adjustments in reorder points and quantities aligning with demand patterns, seasonality, and market trends. Understanding the timelines of seasonal demands in relation to the lead times of products is crucial to plan adequately for stock replenishments during peak seasons.

Diversifying Your Supply Chain

Another efficacious strategy to circumvent the limitations of reorder points is the diversification of your supply chain. Relying on a single supplier for inventory can lead to significant risks, including production halts and stockouts.

Diversifying suppliers across different geographic regions can safeguard against local disruptions such as natural disasters or political instability. Supplier diversification can lead to improved bargaining power and potentially better pricing or terms. Thus, having a diverse supplier base can enhance your inventory management and make your reorder point strategy more robust and resilient.

Beyond traditional calculations, advanced reorder point techniques can augment your inventory management. Techniques such as the use of Economic Order Quantity (EOQ) and Just-in-Time inventory management offer more efficient ways to manage inventory levels and optimize reorder points.

Adopting advanced forecasting methods and data analytics can assist businesses in adjusting their reorder points more accurately based on analysis of customer demand and identification of seasonal trends.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a method centered on identifying the order quantity that is most cost-effective in order to reduce combined inventory holding and ordering costs. Unlike reorder points that emphasize timing, EOQ assists businesses in identifying the optimal quantity to order by focusing on cost efficiency.

The EOQ formula is a quantitative tool that includes setup, production, and storage costs to determine the most favorable product quantity for a business. Implementing EOQ can offer substantial benefits such as:

- Improved order fulfillment

- Reduced waste

- Lowered storage costs

- Potential to leverage quantity discounts

Just-in-Time Inventory Management

Another progressive technique that can amplify your reorder point strategy is Just-in-Time inventory management. Originated from Toyota’s manufacturing system, it is designed to minimize inventory levels by ordering supplies only as needed.

This technique aims to reduce inventory costs by maintaining minimal inventory and ordering goods only as needed. By effectively implementing Just-in-Time inventory management, businesses can significantly reduce their inventory costs and optimize their reorder points.

In summary, understanding and implementing reorder points in your business can significantly enhance your inventory management. By effectively calculating and adjusting reorder points, managing safety stock, and collaborating with suppliers, businesses can maintain optimal inventory levels and avoid costly stockouts. Advanced techniques such as EOQ and Just-in-Time inventory management offer even more efficient ways to manage inventory. With the right strategies and tools in place, businesses can make the most of reorder points and achieve effective inventory control and cost efficiency.

Frequently Asked Questions

A reorder point is the inventory level at which you should order new stock to avoid running out. It helps trigger the replenishment process to maintain sufficient inventory for customer demand.

To calculate lead time demand, multiply the lead time for a product by its average daily sales. This gives you the total quantity of a product consumed during its lead time.

What is the role of safety stock in the reorder point formula?

The role of safety stock in the reorder point formula is to account for unexpected demand surges and delivery delays by serving as a buffer to prepare for potential fluctuations in demand or supply.

To implement reorder points in your business, use inventory management software, regularly review and adjust your reorder points, and collaborate with suppliers. This will greatly improve your inventory management and prevent stockouts.

Advanced reorder point techniques such as Economic Order Quantity (EOQ) and Just-in-Time inventory management offer more efficient ways to manage inventory levels and optimize reorder points. Consider implementing these techniques for improved inventory management.

Going Beyond the Reorder Point: Empower Your Wholesale Distribution Business

Mastering the reorder point formula is a valuable skill, but for wholesale distributors, optimizing your entire operation is key to success. Orders in Seconds provides the tools and automation you need to streamline your business and thrive.

Orders in Seconds empowers your sales team with error-free order processing and real-time data access, regardless of their location. This frees them to focus on strategic initiatives and building strong customer relationships by automating repetitive tasks like order processing and data entry.

Orders in Seconds solutions go beyond formulas, empowering you to optimize important aspects of your wholesale distribution ecosystem.

Schedule a FREE demo today and see how we can transform your business!