Order picking accuracy affects your warehouse’s efficiency and customer satisfaction. Inaccuracies can lead to customer complaints, returns, and reputational damage. Learn what it is, why it matters, and how you can improve it.

Key Takeaways

- Order picking accuracy is critical for efficient warehouse operations, impacting costs and customer satisfaction significantly.

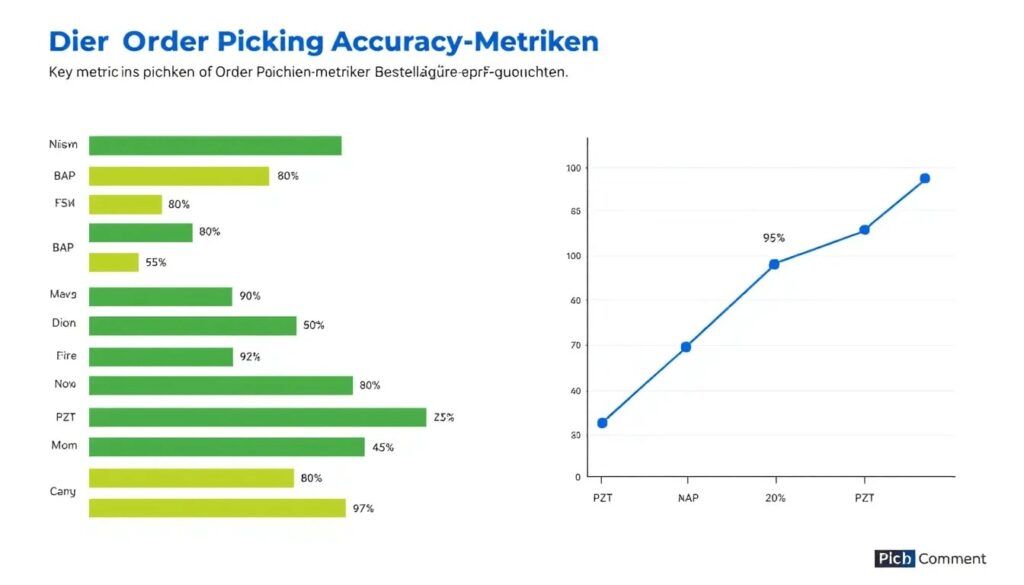

- Key performance metrics such as Picking Accuracy Rate, Order Picking Time, and Cost Per Pick are essential for measuring and enhancing order picking accuracy.

- Implementing advanced technologies like Warehouse Management Systems, pick-to-light systems, and voice-directed picking can substantially improve order picking accuracy and operational efficiency.

- Measuring performance metrics to meet customer demand effectively is crucial. Understanding order picking accuracy, fill rate, and the total order cycle time ensures that inventory aligns with fluctuations in consumer needs.

Table of Contents

- Introduction to Warehouse Management

- Understanding Order Picking Accuracy

- Key Metrics to Measure Order Picking Accuracy

- Common Causes of Poor Order Picking Accuracy

- Best Practices to Enhance Order Picking Accuracy

- Reducing Operational Costs

- Quality Control Checks

- Data-Driven Decision Making

- Technology Solutions for Accurate Order Picking

- Case Studies: Success Stories in Improving Order Picking Accuracy

- Summary

- Frequently Asked Questions

- Simplify Accuracy. Power Up Productivity.

Introduction to Warehouse Management

Warehouse management is a crucial aspect of any business that involves storing and shipping products. It encompasses a range of activities, including receiving, storing, and shipping inventory, as well as managing the warehouse space and personnel. Effective warehouse management is essential for ensuring customer satisfaction, reducing operational costs, and improving overall efficiency. A key component of warehouse management is the order picking process, which involves selecting and gathering products from storage to fulfill customer orders. There are various order picking methods, including batch picking, wave picking, and zone picking, each with its own advantages and disadvantages. By implementing a warehouse management system (WMS) and optimizing the picking process, businesses can improve order accuracy, reduce picking errors, and increase customer loyalty.

Understanding Order Picking Accuracy

Order picking accuracy is the heartbeat of efficient warehouse operations, defining how precisely items are selected for customer orders. This accuracy isn’t just a statistic but a critical measure that can make or break a business. Accurate order picking reduces costs and enhances overall facility operation, leading to increased customer satisfaction.

Ensuring the correct item is picked is crucial for efficiency and accuracy.

Given that order picking constitutes approximately 55% of operating expenses, it’s evident why improving this process is paramount. Understanding the nuances of order picking accuracy and its significance is essential.

Order picking accuracy is defined as the percentage of correct items picked for customer orders. It focuses solely on the picking stage, unlike overall order accuracy which spans the entire fulfillment process. The goal is to ensure that each item selected matches precisely what the customer ordered.

Typically, industry standards place the average order picking accuracy at 99.4%. High picking accuracy not only boosts operational efficiency but also enhances customer satisfaction, as it often leads to improved overall order accuracy.

Accurate order picking is essential for several reasons:

Primarily, it boosts customer satisfaction by reducing shipping errors and ensuring that customers receive exactly what they ordered to fulfill customer orders.

Inaccuracies can lead to customer complaints, returns, and reputational damage.

This accuracy also reduces the costs associated with returns and re-shipments, directly impacting the warehouse’s bottom line and leading to more accurate orders.

Moreover, accurate order picking is crucial for maintaining a good reputation in the market. It minimizes operational inefficiencies and costs, which is vital given that more than 50% of warehouse operating costs are attributed to customer order picking.

Communicating how to measure order accuracy goals clearly helps align the team and achieve higher accuracy rates.

Key Metrics to Measure Order Picking Accuracy

Measuring order picking accuracy with key performance indicators (KPIs) is crucial for improvement. These metrics help track the efficiency and effectiveness of the picking process. High order picking accuracy enhances customer trust and loyalty, which are vital for business success.

Selecting the right picking strategy based on order volume is crucial for efficiency.

Incorporating a stock performance dashboard that includes key picking KPIs is crucial for effective management. Let’s explore three primary metrics: Picking Accuracy Rate, Order Picking Time, and Cost Per Pick.

Picking accuracy rate is calculated by dividing the number of error-free items picked by the total number of items picked, then multiplying by 100. For instance, if 196 items are accurately picked out of 200 items ordered, then the picking accuracy rate is 98%.

Picking Accuracy Rate Formula:

(Total Number of Items Picked / Number of Correctly Picked Items) × 100

Picking Accuracy Rate Example: (196 / 200) * 100 = 98%

A company’s targets for Picking Accuracy Rate depend on various factors, including industry, business model, technology adoption, and customer expectations. However, here are some generally accepted good standard percentages:

🌍 World-Class: 99.9% or higher – This is a challenging but achievable target for organizations with highly optimized processes and technology.

🌟 Excellent: 99% or higher – Leading companies often strive for this level of accuracy, indicating a very efficient and reliable picking process.

👍 Good: 98% or higher – This means that, on average, 98 out of every 100 items picked are correct.

⚠️ Poor: Below 98% – A picking accuracy rate in this range indicates a significant number of errors in the item selection process. This likely leads to frequent wrong items or incorrect quantities being picked, causing downstream issues and customer dissatisfaction.

A high picking accuracy rate is vital for ensuring customer satisfaction and operational efficiency.

The time taken to pick an order is a time consuming critical measure of operational efficiency in warehouses. Evaluating the average number of orders picked per hour (UPH) highlights the efficiency of the picking process.

Exploring different methods can optimize fulfillment efficiency, particularly for varying order volumes.

Different picking methods provide unique benefits related to efficiency, accuracy, and speed, particularly when utilizing a picking method.

Calculating the cost per pick involves dividing the total picking operation costs by the total number of picks. Different order picking methods, such as batch picking or discrete picking, can significantly impact ROI by balancing operational efficiency and labor costs.

Common Causes of Poor Order Picking Accuracy

Despite best efforts, several factors can lead to poor order picking accuracy. Human error, inefficient warehouse layout, and inadequate inventory management are among the top culprits. Addressing these issues is vital for enhancing accuracy and overall warehouse performance.

Most order processing errors occur during the picking and packing phases of fulfillment.

Let’s dissect these common causes to understand how they impact the picking process and what can be done to mitigate them.

Human error remains one of the most frequent causes of picking errors in warehouses. Mispicks, where incorrect items or quantities are selected, are common. Minimizing human error is key to improving order accuracy and overall warehouse performance.

Training and process improvements can greatly reduce human error in order picking, thereby boosting customer satisfaction and lowering operational costs related to correcting mistakes.

An inefficient warehouse layout can lead to increased picking errors, as it may confuse pickers and slow down the picking process. Effective warehouse design and flow are vital for improving warehouse efficiency and order picking efficiency.

Tracking inventory count accuracy by designated location is crucial for efficiency.

Properly labeling SKUs in a warehouse ensures that pickers can easily identify items. Zone or wave picking can be advantageous for larger warehouses. It helps to optimize the picking process effectively.

Disorganized inventory and stock control issues can lead to inaccurate order picking. Effective inventory management with real-time visibility of SKUs, quantities, and locations is vital for managing inventory and maintaining high order accuracy. Implementing real-time inventory tracking often leads to significant reductions in picking errors, making it crucial for maintaining order accuracy.

Best Practices to Enhance Order Picking Accuracy

Adopting best practices can significantly enhance order picking accuracy. Utilizing modern technology and optimizing warehouse layouts are strategies designed to streamline the picking process and minimize errors.

Optimizing fulfillment operations during the picking and packing phases is crucial. Evaluating and providing feedback on these operations can reduce errors and improve efficiency.

Let’s explore some of the most effective practices that can help you achieve accurate order picking, as these practices make the most sense.

A Warehouse Management System (WMS) automates order management system picking processes, boosting operational efficiency. WMS optimizes order picking processes and enhances accuracy and efficiency in warehouse processes and warehouse operations, all overseen by a warehouse manager using warehouse management software.

Technologies such as pick-to-light systems and voice picking provide visual and auditory guidance, enhancing picker productivity. Hands-free operation simplifies the picking process and enhances safety.

Order picking in warehouses can utilize methods such as batch picking, zone picking, and wave picking. Batch picking enables pickers to fulfill multiple orders simultaneously in one trip, significantly increasing efficiency by reducing travel time through multi order picking, the picking and packing process, single order picking, the packing process, warehouse order picking, and the order picking process.

Choosing the right picking strategy based on order volume is crucial for optimizing fulfillment efficiency, especially for larger orders.

Zone picking divides the warehouse into specific areas with assigned pickers, promoting efficiency and effectively managing complex orders. Wave picking enhances order picking by allowing simultaneous picking based on predefined criteria, while cluster picking groups orders into distinct bins for optimal fulfillment.

Regular training on warehouse management strategies enhances employee understanding and adherence to best practices. Setting goals for optimizing and improving order accuracy rates guides training and development efforts.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Are you making one of the top 5 mistakes that plague wholesale distributors? Download our free eBook to find out. We’ve also included tips and guidance to help you save time and avoid costly mistakes.

Reducing operational costs is a key goal for any business, and warehouse management is no exception. One way to achieve this is by implementing efficient order picking processes, such as batch picking or wave picking, which can help reduce labor costs and minimize waste. Additionally, investing in a warehouse management system (WMS) can help automate processes, such as inventory tracking and order fulfillment, which can save time and reduce errors. By streamlining warehouse operations and reducing operational costs, businesses can improve their bottom line and stay competitive in the market. Furthermore, a WMS can provide real-time visibility into inventory levels, allowing businesses to make data-driven decisions and optimize their inventory management. By reducing operational costs and improving efficiency, businesses can focus on growth and customer satisfaction.

Quality Control Checks

Quality control checks are an essential part of the order fulfillment process, ensuring that products are accurate and of high quality before they are shipped to customers. This involves verifying that the correct products are being picked and packed, and that they are in good condition. By implementing quality control checks, businesses can reduce the risk of errors and improve customer satisfaction. A warehouse management system (WMS) can help automate quality control checks, such as scanning products as they are picked and packed, to ensure accuracy and efficiency. Additionally, a WMS can provide real-time visibility into the picking and packing process, allowing businesses to identify and address any issues quickly. By prioritizing quality control checks, businesses can build trust with their customers and establish a reputation for reliability and quality.

Data-Driven Decision Making

Data-driven decision making is critical in warehouse management, as it enables businesses to make informed decisions about their operations and optimize their processes. A warehouse management system (WMS) can provide valuable insights into warehouse operations, such as inventory levels, order fulfillment rates, and picking efficiency. By analyzing this data, businesses can identify areas for improvement and make data-driven decisions to optimize their operations. For example, a business may use data to determine the most efficient picking method, such as batch picking or wave picking, or to identify opportunities to reduce operational costs. By leveraging data and analytics, businesses can improve their overall efficiency, reduce errors, and enhance customer satisfaction. Additionally, a WMS can provide real-time visibility into inventory levels, allowing businesses to make informed decisions about inventory management and optimize their supply chain.

Technology Solutions for Accurate Order Picking

Technology significantly enhances order picking accuracy. Tools like barcode scanners and automated order picking systems reduce human errors and improve efficiency. Specialized equipment, like automated order picking systems, is integral to enhancing picking efficiency.

Let’s explore some of the most impactful technology solutions available today.

Pick-to-light systems use LED lights to guide pickers to correct storage locations, providing visual guidance that ensures items are selected quickly and accurately.

Voice-directed picking uses voice commands to guide pickers hands-free. Workers verbally confirm picks, streamlining the process and reducing errors. Voice-directed picking can significantly enhance order accuracy and improve efficiency through manual picking.

This technology increases productivity and improves worker satisfaction by simplifying tasks.

Automated mobile robots transport items independently, reducing reliance on human labor, including warehouse workers. These robots are vital in modern warehouse operations, enhancing efficiency and helping to automate processes while reducing labor costs. Additionally, automated mobile robots help reduce costs by minimizing labor expenses.

By enhancing efficiency and precision, automated mobile robots boost order picking accuracy in high-volume warehouses.

Case Studies: Success Stories in Improving Order Picking Accuracy

Life Extension, a vitamin supplement company, adopted a mobile solution that boosted order efficiency and speed, while enhancing picking quality and visibility. National Food Products Company in the UAE used mobile barcoding to improve outbound visibility and speed in their picking and shipping operations.

These case studies showcase practical strategies and technologies that companies use to enhance order picking accuracy. Adopting technology-driven solutions like mobile applications and barcoding has proven effective for companies aiming to improve order picking accuracy.

Summary

In summary, improving order picking accuracy is vital for reducing costs, enhancing customer satisfaction, and streamlining warehouse operations. By understanding what order picking accuracy entails, measuring key metrics, addressing common pitfalls, and implementing best practices and technology solutions, you can transform your warehouse operations.

Embrace these strategies to achieve flawless order picking and watch your operational efficiency soar. The path to a more efficient warehouse starts with accurate order picking – make it your priority today.

Frequently Asked Questions

Order picking accuracy is the percentage of correctly selected items for customer orders, emphasizing the crucial picking stage in the fulfillment process. Achieving high accuracy is vital for customer satisfaction and operational efficiency.

A straightforward order picking method, like single order picking, can ensure high accuracy.

Accurate order picking is crucial as it enhances customer satisfaction, lowers operational costs, and improves overall warehouse efficiency. Prioritizing accuracy in this process ultimately leads to better business outcomes.

To measure order picking accuracy effectively, track the Picking Accuracy Rate, Order Picking Time, and Cost Per Pick, as these metrics provide insights into the efficiency and effectiveness of your picking process. This approach will help you identify areas for improvement and maintain high standards in order fulfillment.

Poor order picking accuracy typically arises from human error, an inefficient warehouse layout, and inadequate inventory management. Addressing these issues is essential for improving accuracy and operational efficiency.

Implementing pick-to-light systems, voice-directed picking, and automated mobile robots can significantly improve order picking accuracy by minimizing human errors and increasing overall efficiency.

Simplify Accuracy. Power Up Productivity.

Picking errors don’t have to be the cost of doing business. With the OIS Inventory app, streamline your warehouse order fulfillment process and boost picking accuracy across the board. Easily view your daily orders, filter by picking status, and eliminate costly errors—all from one stress-free, easy-to-use mobile app.

Ready to reduce errors and reclaim efficiency? Let’s talk!