A backorder is when an item is not currently in stock, but customers can still order it with the guarantee of future delivery once restocked. Backorder items are a common occurrence in inventory management and can significantly impact business strategy and customer experience. This is different from an out-of-stock item, which has no definite restock date. eCommerce businesses face particular challenges with backorders, such as managing customer dissatisfaction and maintaining brand reputation. This guide explains the causes of backorders, their impact on customers, and how businesses can manage them effectively.

Introduction to Backorders

Backorders occur when a customer places an order for a product that is currently out of stock, but the company expects to replenish its inventory soon. This situation can arise due to various reasons, such as supply chain issues, demand exceeding supply, or insufficient stock levels. When backorders occur, it indicates that the current inventory cannot meet customer demand, leading to a temporary delay in fulfilling orders.

Effective inventory management is crucial in handling backorders efficiently. By understanding the causes of backorders and implementing strategies to minimize them, businesses can reduce the negative impact on customer satisfaction and maintain a competitive edge in the market. Clear communication with customers about the status of their orders and expected restock dates is essential to manage their expectations and maintain their trust.

In summary, backorders are a common challenge in inventory management, but with proactive measures and effective communication, businesses can navigate these situations successfully and keep their customers satisfied.

Key Takeaways

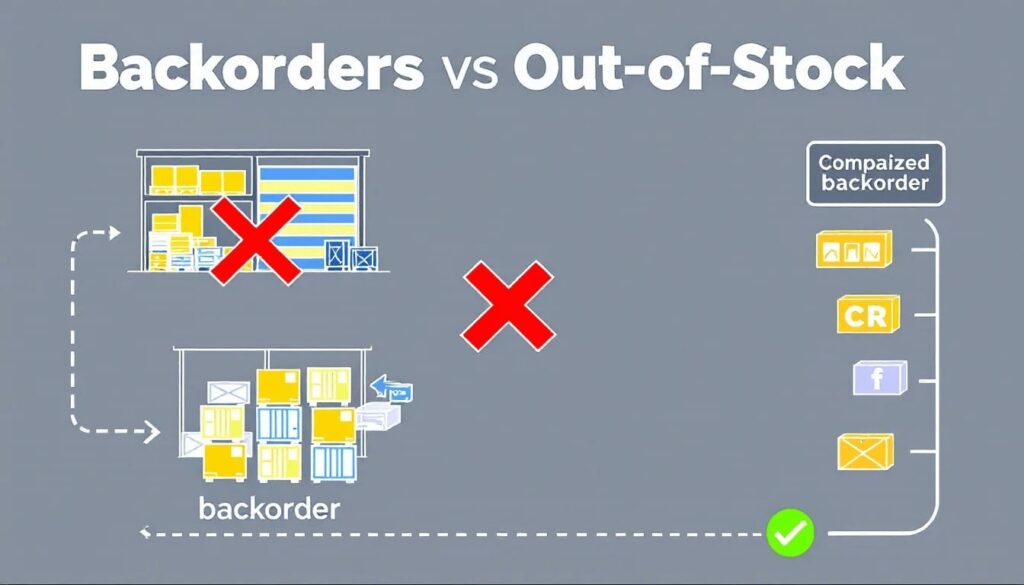

- A backorder is an unfulfilled customer order with an expected future delivery date, differing from out-of-stock items that lack an assurance of restock.

- Key causes of backorders include high demand exceeding supply, supply chain disruptions, and inaccurate forecasting, which businesses must understand to minimize their impact.

- Effective management of backorders involves transparent communication with customers, adjusting reorder points based on demand, and diversifying suppliers to ensure steady product availability.

- A partial backorder occurs when a supplier fulfills only part of an order, which can lead to communication challenges, supply chain issues, and complications in order fulfillment.

- Converting backorders into sales orders is crucial for efficient logistics and maintaining customer satisfaction, as it ensures timely delivery and proper inventory management.

Table of Contents

- What Is a Backorder?

- Why Do Backorders Happen?

- Effects of Backorders

- Managing Backorders Effectively

- Backorder Fulfillment

- Advantages of Accepting Backorders

- Disadvantages of Backorders

- How to Account for Backorders

- Best Practices for Minimizing Backorders

- Backorders vs. Out-of-Stock Items

- Examples of Backorders

- Customer Service & Backorders

- Summary

- Frequently Asked Questions

- Streamline Your Warehouse Operations with OIS Inventory

What Is a Backorder?

A backorder is an unfulfilled customer order due to a lack of inventory, indicating that demand exceeds supply. Unlike out of stock items, backordered items are expected to be delivered by a specific future date, allowing customers to purchase them with the assurance of future shipment once inventory is replenished. This means that even if an item is not available for immediate shipping, customers can still place an order with the promise of receiving it at a later date, contributing to backorder fulfillment. Understanding what backorder mean is essential for customers navigating these situations.

Once a backorder is recorded, it is translated into a purchase order for fulfillment. Additionally, backorders are recorded on the company’s books to maintain accurate financial records. When a customer places an order for a backordered item, they may still be charged for backorder payments before the order ships. This practice helps businesses maintain cash flow and manage their finances effectively. Moreover, orders containing backordered items may be shipped in separate shipments, with available products shipped for immediate shipment. This ensures that customers receive part of their order without unnecessary delays using their preferred payment method.

Backorders work as a strategic tool for businesses to manage inventory and meet customer demand without holding excess inventory. Offering backorders helps companies keep customers engaged and committed to their brand, even during stock shortages. However, managing backorders requires careful planning and communication to ensure customer satisfaction and minimize disruptions.

Why Do Backorders Happen?

Backorders occur for various reasons, reflecting fluctuations in demand and the effectiveness of inventory management. High customer demand, supply chain issues, and inaccurate forecasting are some of the primary factors contributing to backorders. Understanding these reasons is crucial for businesses to minimize backorders and maintain customer satisfaction. Backorders contribute to the company’s backlog, affecting inventory management and accounting practices.

We’ll explore how demand exceeding supply, supply chain disruptions, and inaccurate forecasting lead to backorders. By understanding these causes, businesses can implement strategies to mitigate their impact and ensure smoother operations.

Backorders occur when demand is greater than supply. This situation leads to customers having to wait for their orders. Loyal customers often show patience when waiting for backordered products, particularly those that are unique or high in demand. However, if delays are frequent, these loyal customers may explore alternatives and potentially switch to competitors. This is common in various industries, especially during product launches or successful marketing campaigns. For instance, when Apple launches new devices, it often faces high demand, resulting in backorders due to limited initial supply. Similarly, next-gen consoles in the gaming industry frequently experience backorders as consumers eagerly await their release.

Seasonal items like lawn equipment in home improvement retailers also encounter backorders due to surges in customer demand during specific times of the year. High demand for backordered items is often seen during holidays when tech gadgets are popular gifts. Successful marketing campaigns can also play a significant role in generating the highest demand, leading to backorders.

Essentially, backorders happen when businesses can’t cover unusual demand due to insufficient stock levels. Understanding these patterns allows companies to better prepare for future demand and avoid stockouts, ensuring they can fulfill backorders and meet customer needs without holding excess inventory.

Supply chain issues are another major contributor to backorders. Transportation delays or shortages of raw materials can disrupt the flow of necessary materials, leading to backorders. Planned closures of suppliers or unexpected weather events and natural disasters can exacerbate these disruptions, causing significant inventory challenges and backorders.

Relying solely on a primary manufacturer can increase the risk of supply chain disruptions. Diversifying the supplier network and having backup suppliers can ensure a steady product supply during disruptions, as companies like Apple effectively implement this strategy to prevent stockouts and maintain business resilience.

The bullwhip effect, where small fluctuations in demand at the retail level cause larger variations in demand at the wholesale, distributor, and manufacturer levels, can also amplify demand fluctuations, resulting in backorders and a sudden spike in demand. Effective inventory management and proactive measures are essential to mitigate these supply chain issues and maintain a steady supply of products.

Inaccurate forecasting is a primary reason for the occurrence of backorders. Poor forecasting leads to difficulty in calculating demand needs, resulting in insufficient stock levels to meet customer demand. Human errors, such as forgetting to replenish a SKU or miscalculating inventory, can significantly contribute to inaccuracies in demand forecasting.

Utilizing advanced inventory management systems that automate stock monitoring and reorder processes enhances the overall accuracy of demand forecasting. By leveraging past sales data and emerging market trends, businesses can make more accurate demand predictions and minimize backorders caused by unforeseen circumstances and unexpected surges in demand. Additionally, leveraging historical data helps businesses predict future demand accurately, maintain optimal safety stock levels, and effectively manage backorders, ultimately ensuring a strong relationship with customers and mitigating stockouts.

Effects of Backorders

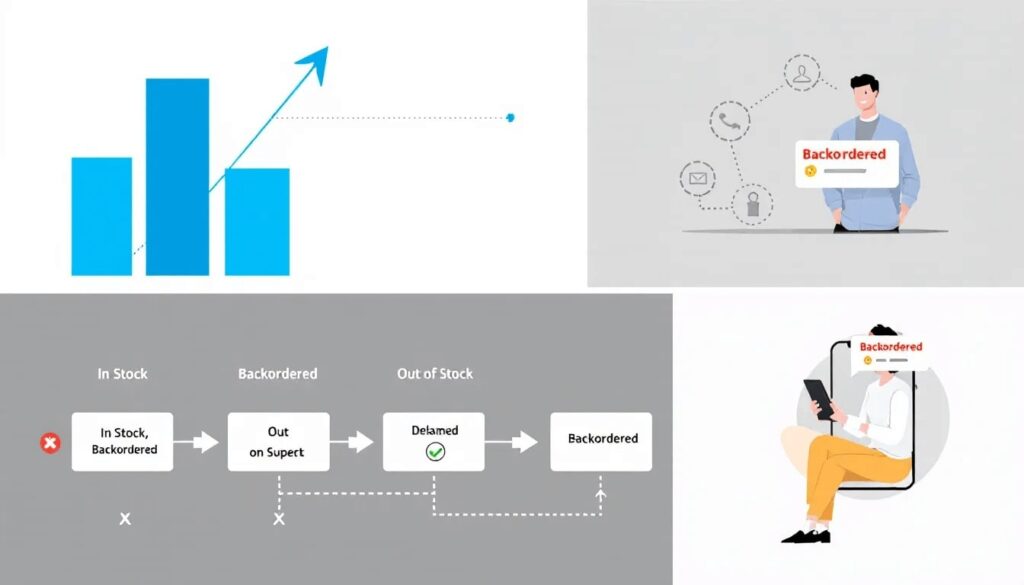

Backorders can have both positive and negative effects on a business. On the positive side, backorders can indicate high demand for a product, which is a promising sign for the company’s sales and revenue. This high demand can provide valuable insights into customer preferences and help businesses adjust their inventory management strategies to better meet future demand.

However, backorders can also lead to several negative consequences if not managed properly. Customer dissatisfaction is a significant risk, as delays in order fulfillment can frustrate customers and lead to canceled orders. This dissatisfaction can damage the company’s reputation and result in lost sales, as customers may turn to competitors with more reliable stock availability.

Additionally, backorders can incur additional costs, such as expedited shipping to fulfill delayed orders and increased inventory holding costs. These extra expenses can eat into the company’s profit margins. Therefore, effective inventory management and clear communication with customers are crucial to mitigating the negative effects of backorders and maintaining a positive customer experience.

Managing Backorders Effectively

Managing backorders effectively is crucial for maintaining customer satisfaction and ensuring smooth business operations. Effective communication with customers, adjusting reorder points, and diversifying suppliers are key strategies to manage backorders. By implementing these strategies, businesses can minimize the negative impact of backorders and maintain a positive relationship with their customers. Additionally, maintaining accurate accounting records to reflect backorders is essential to avoid complications in the accounting process, especially if customers choose to cancel their orders.

We’ll discuss how communicating with customers, adjusting reorder points, and diversifying suppliers can help businesses manage backorders more effectively.

Maintaining transparency with customers about backorders can help manage their expectations and enhance satisfaction. Clearly noting backordered items on the website with expected shipping times is crucial for keeping customers informed. Effective customer service is essential during backorder situations to keep customers happy and maintain their loyalty.

Automated emails and notifications provide timely updates and create excitement, helping to minimize canceled orders due to delays. By keeping customers informed and engaged, businesses can ensure a positive customer experience even during backorder situations.

Accurate reorder points help prevent stockouts and ensure customer satisfaction. Companies analyze historical sales data and current market trends to forecast demand effectively, aligning their inventory with customer needs.

Neglecting to replenish stock can lead to backorders. Prioritizing inventory items allows businesses to selectively increase low safety stock for critical products, reducing backorder risk.

Diversifying suppliers is crucial as it helps ensure a steady supply of products, mitigating the risk of backorders. Utilizing multiple suppliers ensures continuous product availability, thereby reducing the likelihood of backorders.

Backorders can disrupt supply chains, negatively impacting customer satisfaction and creating additional burdens for distributors and manufacturers. Multiple sources for raw materials and finished products help businesses better manage supply chain disruptions and meet customer demand.

Backorder Fulfillment

Backorder fulfillment refers to the process of fulfilling customer orders for items that are currently out of stock. This process involves several key steps to ensure that customers receive their orders as soon as the products become available. The first step is to notify the customer of the backorder status and provide an estimated delivery date. Keeping customers informed about the status of their orders helps manage their expectations and maintain their trust.

Once the backordered items are back in stock, the next step is to prioritize the fulfillment of these orders. This may involve coordinating with suppliers, managing warehouse operations, and ensuring that the items are shipped promptly. Efficient backorder fulfillment processes are essential to minimize delays and improve customer satisfaction.

By implementing effective backorder fulfillment strategies, businesses can reduce the risk of lost sales and maintain a competitive edge in the market. Ensuring timely communication and prompt shipping of backordered items helps build customer loyalty and enhances the overall customer experience.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Are you making one of the top 5 mistakes that plague wholesale distributors? Download our free eBook to find out. We’ve also included tips and guidance to help you save time and avoid costly mistakes.

Accepting backorders offers several advantages for businesses. A systematic approach to backordering helps maintain a connection with customers, reducing the chances of losing sales during stockouts. Allowing backorders enables retailers to generate additional sales even when items are not immediately available. Additionally, businesses can choose to accept backorders to further enhance their sales strategy.

For small businesses, accepting backorders provides flexibility in managing inventory without the risk of overstocking. This approach can also lead to decreased storage costs by minimizing the need for large inventory holdings. Selling items through an online store can offer backorders and enhance customer loyalty by enabling customers to secure products that are in high demand.

Disadvantages of Backorders

Despite their advantages, backorders also come with several disadvantages. Backorders can contribute to a decrease in market share as customers opt for brands with more reliable stock availability. Frequent backorders may lead customers to cancel orders or switch to competitors, resulting in a loss of sales.

High backorder levels may result in operational disruptions, straining resources across finance and logistics teams. Additionally, backorders bad can damage brand reputation due to lengthy fulfillment times and may indicate possible problems with inventory management.

How to Account for Backorders

Backordered sales are recorded as backorders, not as completed sale. This distinction is important for accurate financial reporting and inventory management. If a customer decides to cancel a backorder, it does not affect the company’s bottom line. The backorder rates measure the portion of total orders that are backordered, providing insights into inventory management effectiveness.

Recording backorders in accounting helps prevent reconciliation issues if a customer cancels or if stock cannot be acquired. Backorders can be expressed as a dollar figure or by the number of units ordered/sold, providing a clear picture of the company’s backlog and helping businesses plan for future demand.

Best Practices for Minimizing Backorders

Effective inventory management and proactive communication can significantly reduce backorder occurrences. Regular inventory monitoring is essential for anticipating demand and avoiding stockouts. Utilizing intelligent forecasting in inventory management prevents backorders by maintaining stock levels.

We’ll explore best practices for using real-time data, developing contingency plans, and optimizing inventory management systems to minimize backorders and ensure smooth operations.

Real-time data is crucial for effective inventory management and is vital for preventing backorders. Real-time data helps businesses avoid stockouts and supports informed decision-making regarding stock levels. Automated alerts notify stakeholders when stock levels are low, ensuring timely actions.

Products must be placed on warehouse shelves before backorders can be processed, highlighting the importance of efficient storage and logistics. Accurate real-time data enhances inventory tracking and helps inform restocking decisions, minimizing backorder risks. Leveraging real-time tracking and automated alerts helps businesses maintain optimal inventory levels and reduce backorders.

Contingency plans are essential for handling an unexpected surge in demand. Sourcing from alternative suppliers mitigates the impact of demand spikes, ensuring product availability even during supply chain disruptions.

Advanced inventory management system streamline operations by providing accurate and timely information about stock levels and storage space. Real-time data and automated alerts allow businesses to monitor stock levels effectively and prevent backorders, ultimately reducing less inventory and inventory carrying costs.

Developing contingency plans, such as sourcing from alternative suppliers, prepares businesses to manage unexpected surges in demand. Adjusting reorder points maintains optimal inventory levels and reduces backorder risk. Optimizing inventory management systems ensures better inventory management and minimizes backorders.

Backorders vs. Out-of-Stock Items

Backordered products differ from out-of-stock items because they have an anticipated arrival date. Items on backorder are guaranteed to return to stock, unlike out-of-stock items, which do not have that assurance. This distinction is crucial for customers, as it influences their purchasing decisions and expectations.

When a product is backordered, it typically involves a longer shipping timeframe compared to items readily available in stock. The choice between marking an item as backordered or out of stock often relies on the specific business model and customer expectations. Understanding these differences helps businesses manage customer expectations and maintain satisfaction.

Examples of Backorders

Popular product launches often trigger a spike in demand that can lead to backorders. Effective marketing strategies can create significant consumer interest, resulting in high demand and backorders. For instance, Apple effectively uses a diversified supplier strategy to manage backorders, ensuring a steady supply of products and maintaining customer satisfaction through a successful marketing campaign and valuable market insights.

Understanding these examples helps businesses implement similar strategies to manage high demand situations and minimize backorders. Effective inventory management, proactive communication, and supplier diversification are crucial for handling backorders successfully.

Customer Service & Backorders

Effective communication is essential for managing customer expectations regarding backorders. Here are some key points to consider:

Keeping customers informed about the status of their orders helps to maintain trust and satisfaction.

Apologizing for delays and providing timely updates can help maintain customer relationships and foster loyalty during backorder situations.

Automated notifications can enhance customer service by keeping customers updated on backorder status, which is crucial for providing a better experience.

Handling backorder inquiries increases the complexity of customer service operations as customers may have specific questions and concerns about their orders. Businesses should train their customer service teams to handle these inquiries efficiently, ensuring that all customer concerns are addressed promptly. For more information, refer to our backorder faqs.

By maintaining a high level of customer service during backorder situations, businesses can turn potential frustrations into opportunities to build stronger customer relationships.

Summary

Backorders are an inevitable part of business operations in many industries. Understanding the causes of backorders—ranging from high customer demand and supply chain issues to inaccurate forecasting—can help businesses implement effective strategies to manage them. Clear communication with customers, accurate demand forecasting, and diversified suppliers are key to managing backorders effectively and maintaining customer satisfaction.

By adopting best practices such as utilizing real-time data, developing contingency plans, and optimizing inventory management systems, businesses can minimize the occurrence of backorders and ensure smooth operations. Accepting backorders can offer advantages like increased sales and customer loyalty but also comes with challenges such as potential market share loss and operational disruptions. Balancing these aspects is crucial for businesses to thrive in a competitive market.

Frequently Asked Questions

A backorder refers to an unfulfilled customer order caused by insufficient inventory, indicating that demand surpasses supply. Customers can still place orders with the understanding that products will ship when stock is available again.

Backorders happen when supply chain disruptions, high customer demand, or poor demand forecasting result in insufficient stock levels. Addressing these issues can help prevent backorders and improve customer satisfaction.

To manage backorders effectively, businesses should prioritize clear communication with customers, adjust reorder points based on demand, and diversify their supplier base. This approach ensures transparency and minimizes disruption in the supply chain.

Accepting backorders can significantly enhance your business by driving extra sales, fostering customer loyalty, and optimizing inventory management without the burden of overstocking.

Backordered items can be pre-ordered with an expected arrival date, while out-of-stock items cannot be ordered until they are restocked, lacking a guaranteed date for replenishment.

Streamline Your Warehouse Operations with OIS Inventory

Transform your warehouse operations with OIS Inventory. By leveraging real-time inventory tracking and automated order picking, you can enhance accuracy, reduce backorders, and boost customer satisfaction. Experience streamlined fulfillment and take control of your inventory today.