Product traceability of products tracks every stage of production, ensuring transparency and safety. It’s crucial for compliance and managing recalls in industries like food, healthcare, and automotive. Standards developed by the International Organization for Standardization (ISO) play a significant role in establishing traceability protocols across various industries, thereby enhancing product safety and operational efficiency. This article will explain the benefits, best practices, and applications of product traceability of products.

Key Takeaways

- Product traceability involves tracking every stage of a product’s development, ensuring accountability and compliance, which is especially important in industries such as food, healthcare, and automotive.

- Implementing traceability systems enhances quality control, facilitates efficient recall management, and increases consumer trust by providing transparency about product origins and safety.

- Successful traceability requires a comprehensive strategy, including engaging stakeholders, conducting mock recalls, and utilizing technology for real-time data collection and accurate recordkeeping.

- Identifying defects at the end of the production line is crucial as it links to traceability efforts, facilitating deeper investigations into the origins of issues that arise during production.

Table of Contents

- Understanding Product Traceability

- Key Benefits of Product Traceability

- Industry-Specific Applications of Traceability

- Achieving Effective Traceability

- Implementing Traceability Software

- Internal and External Traceability

- Conducting Mock Recalls

- Case Studies on Successful Traceability Implementation

- Summary

- Frequently Asked Questions

- Enhance Your Product Traceability with Smarter Solutions

Understanding Product Traceability

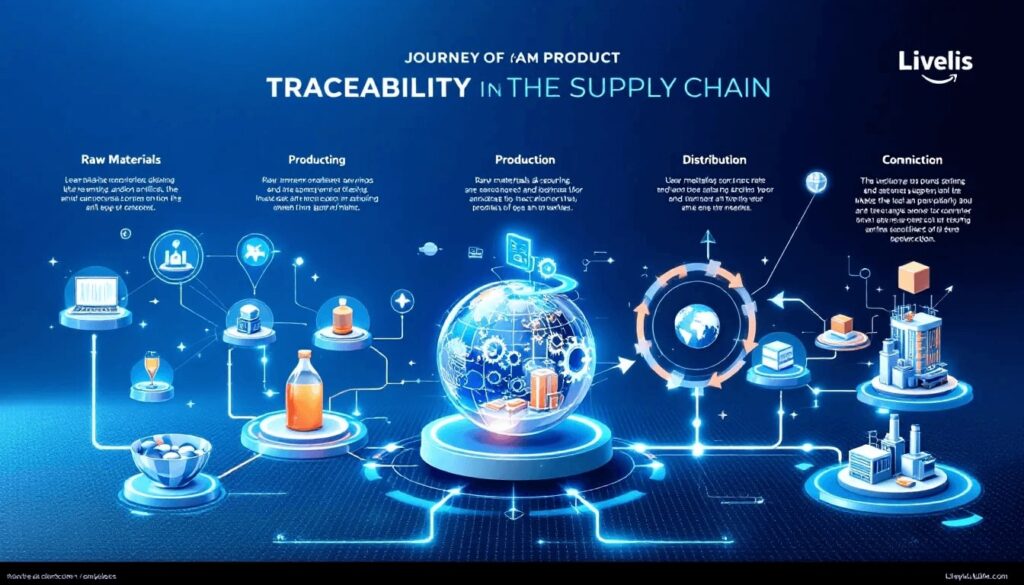

Product traceability refers to tracking the product development cycle and documenting each production stage, from raw materials to finished goods. Traceability allows for tracking every component and process through the supply chain, ensuring full accountability. Transparency is vital in sectors like food, healthcare, and automotive, where safety and quality are critical. In the food industry, tracking the ingredients of a loaf of bread back to its suppliers and production process ensures compliance with regulations and mitigates risk.

International organizations like the International Organization for Standardization (ISO) play a crucial role in setting standards for traceability, enhancing product safety and operational efficiency.

Supply chain traceability allows businesses to monitor the movement of goods from raw materials to final products, providing real-time information on location, quantity, and expiration. This ability is crucial for managing risks, enabling companies to identify and address issues swiftly. In the event of a recall, backward traceability helps pinpoint exact failure points, facilitating efficient product callbacks for faulty batches.

Moreover, traceability systems aid in root cause analysis, promoting continuous improvement and accountability. Regulatory compliance often drives the implementation of these systems, as industries must adhere to stringent standards.

These systems enhance consumer trust by providing transparency and ensuring that products meet safety and quality standards. Understanding traceability measures and its importance enables businesses to implement measures that support operational goals and regulatory obligations.

Key Benefits of Product Traceability

Implementing traceability systems offers numerous benefits, beginning with rigorous quality control. Traceability software enables businesses to monitor product conditions throughout handling, ensuring that quality standards are maintained at every stage. Such oversight is especially critical in industries like food and automotive, where minor deviations can lead to significant repercussions. Real-time data on product status helps identify and rectify issues swiftly, enhancing overall product quality.

Identifying defects at the end of the production line is crucial as it facilitates deeper investigations into the origins of issues, thereby improving traceability efforts and quality control. Traceability systems are crucial in recall management, allowing companies to quickly identify and recall defective products, minimizing harm to consumers and protecting the company’s reputation. For instance, JemD Farms’ implementation of PTI milestones has not only enhanced its reputation for innovation but also improved overall business operations. Similarly, Paramount Citrus’s use of the PTI has increased product traceability and customer satisfaction through improved efficiency. Traceability is increasingly mandated in various industries to meet regulatory standards and ensure product safety. Compliance with industry standards, such as ISO 26262 in automotive manufacturing and traceability regulations, is critical for maintaining safety and quality. Implementing traceability systems allows businesses to enhance customer trust by providing transparent information about product origins and safety. Transparency extends beyond the point of sale, offering insights into product sourcing and fostering a deeper connection with consumers.Industry-Specific Applications of Traceability

Traceability is not a one-size-fits-all solution; its application varies across different industries. From tracking raw materials in the food industry to monitoring components in the automotive sector and managing dependencies in software development, traceability systems are tailored to meet the specific needs of each field. Engaging suppliers and distributors enhances accountability and quality assurance, making traceability an integral part of the production process.

The following subsections will explore the application of traceability in the food industry, automotive industry, and software development, offering detailed insights and real-world examples.

In the food industry, traceability tracks food products from their origin to the consumer, ensuring safety and compliance with industry standards and regulations. Lot number tracking enables food processing plants to recall potentially dangerous food, protecting consumers from harm. Blockchain technology revolutionizes food traceability by ensuring complete transparency in supply chains, as seen with TraceX’s platform tracking products from farm to consumer.

Companies like Frontera Produce and Ocean Mist Farms have demonstrated the benefits of robust food traceability systems. Frontera Produce enhanced supply chain visibility and food safety through the use of GS1 barcodes, while Ocean Mist Farms adopted the Produce Traceability Initiative, leading to improved operational efficiency and enhanced food safety measures.

These examples highlight how food traceability ensures compliance while enhancing business operations and consumer trust.

In the automotive industry, traceability is essential for tracking components during production, which helps manage recalls and maintain quality control. Automotive manufacturers use traceability systems to monitor components throughout the manufacturing process, ensuring compliance with stringent regulations and standards. This is crucial for promptly identifying and addressing defects, enhancing product safety and reliability.

An automotive company using detailed lot number tracking swiftly located and addressed defects during production, significantly improving their recall management process. This boosts customer confidence and ensures compliance with safety regulations, making traceability indispensable in the automotive sector.

In software development, traceability tracks work items and dependencies throughout the project lifecycle, facilitating compliance and quality assurance. This capability is crucial for managing requirements, tracking changes, and aligning development with regulatory standards. Clear records of dependencies help teams promptly identify and address issues, ensuring the final product meets quality and compliance standards.

A tech firm using traceability tools to manage dependencies and track progress reported a 25% reduction in their software development cycle time. This example illustrates how effective traceability can streamline development processes, improve efficiency, and ensure that software products meet industry standards.

Achieving Effective Traceability

Effective traceability requires more than just a system; it demands a comprehensive strategy including proper reporting policies, stakeholder engagement, and continuous improvement. Accurate reporting policies ensure that information about materials, employee tasks, equipment usage, and process issues is documented correctly. This data is crucial for identifying inefficiencies in the supply chain and driving operational improvements.

Identifying defects at the end of the production line is essential as part of a comprehensive traceability strategy. This practice helps in root cause analysis and facilitates deeper investigations into the origins of issues that arise during production.

Engaging stakeholders in the traceability process ensures everyone understands their role and the importance of accurate records. Regularly examining operation steps and conducting mock recalls can uncover ways to better utilize resources, fostering a culture of continuous improvement.

A well-structured traceability matrix enhances communication and facilitates change management, making it essential for achieving full traceability.

Lot number tracking focuses on the origin, quantity, value, expiry dates, and compliance of each batch, making it a fundamental aspect of traceability. It is particularly important for bulk-produced items like food, pharmaceuticals, and fabric. Recording production dates, expiration dates, timestamps, and order numbers helps companies maintain accurate records supporting product recalls and compliance.

RFID tags and individualized barcodes facilitate detailed product tracking, aiding in inventory management and quality assurance. Growers Express implemented GS1 GTINs for case labels, achieving real-time traceability for 18 million cartons shipped annually. Such detailed tracking helps companies achieve traceability and enhance operational efficiency.

Serial number tracking handles individual items like electronics, furniture, and components. It is essential for managing warranties, returns, and repairs, providing an overview of the status, location, and history of each item. Utilizing technologies like barcodes, barcode scanners, and RFID tags helps companies track individual items throughout their lifecycle.

Serial number tracking supports warranty and repair management and enhances customer satisfaction by ensuring prompt and accurate issue resolution. Detailed tracking helps companies maintain high standards of quality and reliability, fostering consumer trust and loyalty.

Real-time data collection maintains accurate visibility of product status throughout the supply chain. Real-time information enhances transparency and accountability as products move through the supply chain.

Mother Earth Organic Mushrooms uses GS1 standards for real-time inventory tracking, ensuring product safety and quality. This is crucial for achieving full traceability and ensuring products meet safety and quality standards.

Implementing traceability software enhances transparency and organizes processes for manufacturers. These systems improve process efficiency and save resources by automating repetitive tasks and streamlining operations. Real-time communications within these systems allow for quick issue responses, ensuring problems are addressed promptly and effectively.

International organizations like the International Organization for Standardization (ISO) play a crucial role in setting standards for traceability software, ensuring consistency and reliability across industries.

When choosing a traceability solution, companies should review case studies from regulated industries to understand the benefits and challenges of different systems. Automated inventory tracking and quality inspection management are standard in modern ERP systems for traceability, providing comprehensive solutions that support compliance and operational efficiency.

Internal and External Traceability

Internal traceability tracks production processes within an organization, ensuring each step is monitored for quality and compliance. Companies use unique identification numbers for each product to facilitate internal traceability and manage inventory effectively. This is crucial for maintaining accurate records and ensuring products meet safety and quality standards.

Identifying defects at the end of the production line is essential for internal traceability, as it allows for deeper investigations into the origins of issues that arise during production.

External traceability assesses the journey of products before and after entering a facility, highlighting supplier and distributor involvement. Sharing traceability information across the distribution network ensures transparency and accountability.

Effective traceability solutions need reliable identification methods and central recordkeeping to track products throughout their lifecycle. The Oppenheimer Group’s use of Advance Ship Notices exemplifies how external traceability can enhance overall accountability.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Are you making one of the top 5 mistakes that plague wholesale distributors? Download our free eBook to find out. We’ve also included tips and guidance to help you save time and avoid costly mistakes.

Conducting Mock Recalls

Mock recalls are crucial for testing traceability systems’ effectiveness and identifying improvement areas. A mock recall simulates a recall process by treating a problem-free product as defective. All actions during the simulation are recorded for analysis, helping companies identify gaps and refine the recall process.

International organizations like the International Organization for Standardization (ISO) play a significant role in setting standards for recall processes, ensuring consistency and reliability across industries.

Mock recalls should be conducted every 12 to 18 months to ensure preparedness for actual recalls. Robust product traceability reduces liability risk by providing detailed records of product components, ensuring efficient and effective recall management.

This practice enhances consumer trust and protects brand reputation.

Case Studies on Successful Traceability Implementation

Several companies have successfully implemented traceability systems, reaping significant benefits. A leading food manufacturer implemented a comprehensive traceability system to monitor their supply chain and ensure food safety. This system allowed quick identification and resolution of issues, reducing recalls and improving regulatory compliance.

Identifying defects at the end of the production line is crucial for effective traceability, as it facilitates deeper investigations into the origins of issues that arise during production.

In the automotive sector, a company using detailed lot number tracking swiftly located and addressed defects during manufacturing processes, significantly enhancing their recall management process. Similarly, a tech firm reduced their software development cycle time by 25% by using traceability tools to manage dependencies and track progress.

These examples highlight the tangible benefits of effective traceability, from improved operational efficiency to enhanced consumer trust.

Summary

Mastering the traceability of products is an ongoing journey that offers significant benefits, from enhanced quality control and streamlined recalls to improved regulatory compliance and customer satisfaction. By understanding and implementing effective traceability systems, businesses can ensure transparency, accountability, and safety across their supply chains. International organizations like the International Organization for Standardization (ISO) play a crucial role in setting standards for traceability, which helps enhance product safety and operational efficiency. Whether in the food industry, automotive sector, or software development, traceability measures are critical for maintaining high standards and fostering consumer trust. As you embark on or refine your traceability initiatives, remember that continuous improvement and stakeholder engagement are key to achieving and sustaining success.

Frequently Asked Questions

Product traceability is the process of tracking a product’s development cycle and documenting its production stages. It is crucial for managing risks, ensuring accountability, and meeting regulatory compliance, particularly in sectors such as food, healthcare, and automotive.

International organizations like the International Organization for Standardization (ISO) play a significant role in setting standards for traceability, enhancing product safety and operational efficiency across various industries.

Traceability significantly enhances businesses by ensuring rigorous quality control and facilitating efficient recall processes. This not only aids in regulatory compliance but also boosts customer satisfaction through prompt issue resolution. Identifying defects at the end of the production line is crucial for quality control and recall management, as it allows for thorough traceability and deeper investigations into the root causes of issues.

Traceability is crucial across various industries, ensuring accountability and quality. In the food industry, it tracks products from origin to consumer, while in automotive and software development, it manages components and dependencies to maintain quality control and compliance.

Achieving effective traceability requires accurate reporting policies, stakeholder engagement, regular mock recalls, and the use of technologies such as RFID tags and barcodes. Additionally, continuous improvement and a well-structured traceability matrix are crucial for success.

Companies can implement traceability software by studying case studies from regulated industries to select an appropriate solution. This approach will enhance transparency, improve process efficiency, and save resources through task automation and real-time data access.

Enhance Your Product Traceability with Smarter Solutions

Mastering product traceability is key to ensuring quality control, regulatory compliance, and consumer trust across industries. By implementing robust tracking systems, businesses can reduce recall risks, improve operational efficiency, and enhance transparency throughout the supply chain.

Meanwhile, remember that Orders in Seconds helps wholesalers, distributors, and manufacturers streamline their traceability efforts with the OIS Inventory App. From lot number tracking to barcode scanning, our solution ensures accurate inventory management and seamless product traceability.