Struggling with stockouts or excess inventory? Effective inventory management ensures you have just the right stock to meet customer demands without tying up excess capital. This article will guide you through the best techniques, benefits, and systems to optimize your inventory management.

Key Takeaways

- Effective inventory management boosts efficiency, reduces waste, and enhances customer satisfaction, leading to increased sales.

- Advanced inventory systems, like automated and cloud-based solutions, provide real-time tracking and insights, minimizing errors and decision-making delays.

- Understanding and implementing inventory methods, such as Just-in-Time and Economic Order Quantity, can significantly streamline operations and reduce costs.

Table of Contents

- Understanding Inventory Management

- Key Benefits of Effective Inventory Management

- Types of Inventory Management Systems

- Common Inventory Management Methods

- Inventory Tracking Techniques

- Integrating Inventory Management with Other Business Processes

- Challenges in Inventory Management and How to Overcome Them

- Case Studies: Successful Inventory Management Implementations

- Choosing the Right Inventory Management System for Your Business

- Future Trends in Inventory Management

- Summary

- Frequently Asked Questions

- Optimize Inventory Management with Smarter Order Picking

Understanding Inventory Management

Inventory management involves ordering, storing, using, and selling stock, ensuring the right products are in the right place at the right time. Effective inventory management aims to optimize stock levels to prevent both excess and shortages, which can disrupt business operations and impact financial health. To effectively manage inventory, inventory valuation is one of the most valuable assets for businesses in sectors like retail and manufacturing, yet it can also represent a liability due to risks like spoilage or theft.

Different industries employ various strategies tailored to their unique needs. A bakery might focus on daily inventory checks for freshness, while a tech company relies on sophisticated systems for real-time stock tracking and management.

The Days Sales of Inventory (DSI) metric measures the average time to convert inventory into sales, crucial for assessing efficiency and guiding purchasing decisions.

Key Benefits of Effective Inventory Management

Effective inventory management boosts efficiency and customer satisfaction. Companies using advanced systems can streamline operations, reduce waste, and ensure product availability. This leads to fewer stockouts and excess stock situations, directly impacting customer satisfaction and loyalty.

A small business that implemented a robust inventory management system achieved a 97% product availability rate, reducing stockouts by 30%, enhancing customer satisfaction, and increasing sales. Such examples illustrate how effective inventory management can transform business operations, making them more efficient and responsive to market demands.

Furthermore, by maintaining optimal inventory levels, businesses can avoid the costs associated with overstocking, such as storage and spoilage, and the risks of understocking, like lost sales and customer dissatisfaction. These practices result in significant cost savings and improved operational efficiency.

Types of Inventory Management Systems

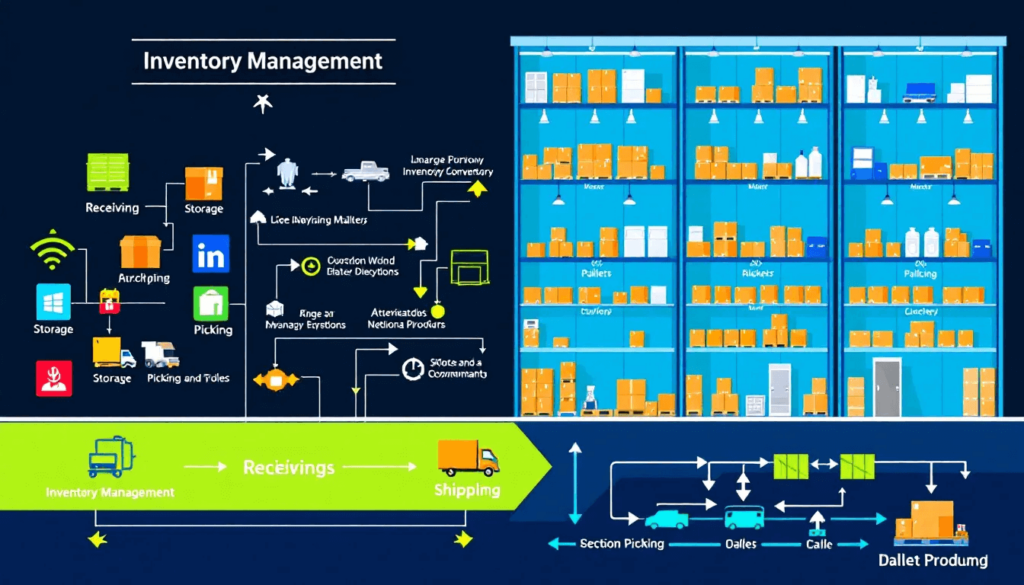

Inventory management systems vary from simple pen-and-paper methods to complex software systems that track inventory in real time. These systems can be categorized into manual inventory management, automated inventory management software, and cloud-based inventory management systems.

Each type has its own set of advantages and is suitable for different business needs, from small retailers to large multinational corporations.

Manual inventory management often involves using spreadsheets to track stock levels and sales effectively. These systems are low-cost, easy to set up, and suitable for businesses with simple needs. For example, a small retail store might use a spreadsheet to manage its inventory, which can be efficient as long as the business operations remain uncomplicated.

However, as business complexity increases, spreadsheet-based systems may become unwieldy and inflexible, lacking the real-time data access necessary for efficient decision-making. When businesses reach this stage, they often need to upgrade to more sophisticated systems that offer greater flexibility and real-time data.

Automated inventory management software offers several key features, including real-time inventory tracking, automated reordering, and comprehensive reporting tools. These systems can drastically reduce the manual effort involved in managing inventory and provide valuable insights for better decision-making. Advanced functionalities, such as AI-driven forecasting and custom low stock alerts, further enhance the performance and reliability of these systems.

Automated inventory management systems offer real-time data and reduce manual intervention, enabling businesses to make swift and informed decisions. This not only improves operational efficiency but also reduces the risk of human error, ensuring more accurate inventory control.

A cloud-based inventory management system tracks stock levels and inventory data via the Internet, offering unparalleled flexibility and accessibility. These systems enable businesses to access inventory data remotely, which is particularly beneficial for companies with multiple locations or remote work setups. The ability to integrate with other tools and systems further enhances their utility.

Scalability is a key consideration for cloud-based systems. As businesses grow and inventory demands increase, these systems can adapt without requiring a complete overhaul, making them a future-proof solution for dynamic business environments.

Common Inventory Management Methods

Common inventory management methods include Just-in-Time (JIT) and Economic Order Quantity (EOQ). Another important method is Materials Requirement Planning (MRP). Each method has its own principles and benefits, tailored to different business needs and operational goals.

Understanding these methods can help businesses choose the most effective strategy for managing their inventory.

The Just-in-Time (JIT) model minimizes holding inventory by coordinating the supply chain precisely to ensure product availability without excess stock. This method can significantly reduce waste associated with holding unsold goods, leading to enhanced profitability. For businesses looking to streamline operations and reduce storage costs, JIT offers a compelling solution.

JIT implementation demands accurate data and reliable suppliers. The benefits include lower holding costs, reduced waste, and improved cash flow. Businesses that successfully implement JIT often see a marked improvement in their operational efficiency and overall profitability.

The Economic Order Quantity (EOQ) model helps businesses determine the ideal order volume that minimizes total inventory expenses. This model balances the costs of ordering inventory with the costs of storing it, aiming to achieve the most efficient level of inventory management. By calculating the optimal order size, businesses can significantly reduce their total inventory costs.

Implementing the EOQ model involves analyzing various factors, such as demand rate, ordering costs, and holding costs. The result is a more efficient inventory system that minimizes costs while ensuring adequate stock levels to meet customer demand.

Materials Requirement Planning (MRP) heavily relies on sales forecasts for accurate inventory replenishment. This method ensures that inventory levels are maintained to meet manufacturing demands, preventing production delays and stockouts. For manufacturers, MRP is an essential tool for planning production schedules and managing inventory effectively.

MRP aligns inventory levels with production needs, maintaining smooth production flow, reducing holding costs, and improving overall efficiency. It’s a vital component of inventory management for companies that need to synchronize their inventory with manufacturing processes.

Inventory tracking is critical for maintaining accurate stock levels and minimizing errors. Techniques like RFID and barcode technology play a significant role in modern inventory management. RFID allows for swift physical inventory counts by scanning entire shelves quickly, while barcode technology helps reduce human errors, leading to greater accuracy and efficiency.

Regular audits, such as daily cycle counting, are essential to ensure inventory data remains accurate. Accurate inventory tracking methods are crucial for reducing errors and improving overall efficiency.

Tracking techniques minimize errors and enhance operational efficiency.

Integrating Inventory Management with Other Business Processes

Integrating inventory management with other business processes, such as accounting and customer service, enhances overall efficiency and accuracy. Modern inventory systems facilitate collaboration among departments, improving customer service by ensuring timely delivery and accurate stock information. Automation of routine tasks, like barcoding and order fulfillment, ensures greater accuracy in inventory control.

Streamlining data collection and reporting requires compatibility with existing software systems. Real-time tracking and auto-generated purchase orders enhance the integration of inventory systems, enabling businesses to monitor inventory levels accurately across multiple warehouses and devices.

Challenges in Inventory Management and How to Overcome Them

Inventory management comes with its own set of challenges, such as frequent inventory write-offs and changes in accounting methods. These issues can indicate underlying problems with selling finished goods or inventory obsolescence. An effective inventory management system can help reduce carrying costs related to storage, handling, and potential losses.

Improved productivity can be achieved through streamlined operations and better organization of stock. The use of RFID technology significantly reduces human error in inventory management by automating the tracking process, serving as both an inventory management and security measure.

Case Studies: Successful Inventory Management Implementations

Case studies demonstrate the practical applications of inventory management techniques and their direct impact on business growth.

Here, we explore how both small businesses and large enterprises have successfully implemented inventory management solutions to achieve significant improvements.

A small retail store faced challenges with managing inventory efficiently and meeting customer demands. By implementing a user-friendly inventory management system, the business saw a remarkable improvement in product availability and reduced stockouts. This change led to a 30% increase in sales, as real-time stock updates allowed them to maintain optimal inventory levels and meet customer expectations.

Some retailers use external support to keep excess stock organized off-site. According to Removals and Storage Experts, short and long-term storage options can help manage seasonal inventory or space constraints without disrupting daily operations.

Better stock management significantly enhanced customer satisfaction, as customers could rely on the store to have the products they needed. This small business example illustrates how effective inventory management can directly contribute to increased sales and customer loyalty.A large multinational corporation employed sophisticated inventory management software, enabling the synchronization of inventory data across multiple warehouses and reducing order fulfillment times by 25%. The advanced inventory software streamlined operations, leading to a 25% reduction in logistical costs and significantly improving operational efficiency.

The implementation of real-time tracking and analytics allowed the company to anticipate market demands and reduce holding costs effectively. This large enterprise saw a boost in customer satisfaction due to timely delivery and accurate stock information.

The case study showcases the transformative impact of advanced inventory management software on a company’s supply chain.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Are you making one of the top 5 mistakes that plague wholesale distributors? Download our free eBook to find out. We’ve also included tips and guidance to help you save time and avoid costly mistakes.

Choosing the Right Inventory Management System for Your Business

Choosing the right inventory management system depends on the size of your business and its specific challenges. Smaller businesses typically prefer simpler, cost-effective solutions like Sortly inventory management software, which is ideal for small businesses. Larger enterprises, on the other hand, require more advanced functionalities and may need to invest significantly in ERP inventory solutions, which can cost between $10,000 and $40,000 for implementation.

Understanding the specific inventory challenges your business faces is essential for selecting an appropriate system. While the adoption of advanced inventory technologies often requires significant investment and training, the benefits in terms of efficiency and cost savings usually justify these costs.

Future Trends in Inventory Management

There are approximately 244,584 inventory control specialists currently employed in the United States. These professionals play a crucial role in ensuring efficient inventory management and control within businesses. The average salary of inventory control specialists is $34,507, reflecting the importance and demand for this role.

The projected career growth for inventory control specialists through 2028 is expected to be strong, offering numerous opportunities for those interested in this field. Roles in inventory control span various industries, including manufacturing, retail, and logistics, providing diverse career paths.

With the increasing emphasis on supply chain efficiency and inventory management, the demand for skilled inventory control professionals is likely to continue growing. This field offers a promising career with opportunities for advancement and specialization.

Summary

Effective inventory management is crucial for boosting efficiency, cutting costs, and enhancing customer satisfaction. From understanding the basics of inventory management to exploring advanced systems and methods, businesses can find the right strategies and tools to optimize their stock levels and streamline operations. Real-world case studies demonstrate the significant impact of implementing robust inventory management systems, whether for small businesses or large enterprises.

As we look to the future, embracing technological innovations like AI and blockchain will be essential for staying competitive. By choosing the right inventory management system and integrating it with other business processes, companies can achieve greater operational efficiency and drive business growth. Now is the time to take action and transform your inventory management practices.

Frequently Asked Questions

The four main steps in inventory management are demand forecasting, inventory tracking, reordering and replenishment, and inventory optimization. By mastering these steps, you can efficiently manage your inventory and boost your success!

Effective inventory management is essential for ensuring that companies can efficiently track, store, and sell their goods while minimizing costs. By optimizing inventory processes, businesses can meet customer demand more effectively and reduce the risk of overstocking or stockouts.

Effective inventory management can greatly enhance your business by improving efficiency, cutting costs, and increasing customer satisfaction through optimal stock levels and timely replenishment. It’s a powerful way to set your business up for success!

There are three main types of inventory management systems: manual systems, automated software, and cloud-based solutions. Choose the one that best fits your business needs to streamline your operations and boost efficiency!

To manage your inventory efficiently, consider using Just-in-Time (JIT), Economic Order Quantity (EOQ), and Materials Requirement Planning (MRP) methods. Each of these strategies can enhance your operations and boost productivity!

Optimize Inventory Management with Smarter Order Picking

Efficient inventory management is about more than just tracking stock—it’s about ensuring seamless order fulfillment. OIS Inventory enhances your operations by streamlining order picking, reducing errors, and accelerating delivery. Improve accuracy, minimize stockouts, and keep up with customer demand by integrating a solution that supports your inventory strategy.

Learn more by scheduling a free demo today!