Warehouses are the backbone of any organization involved in manufacturing, production, or distribution. They are responsible for storing, managing, and transporting goods, materials, and equipment to various locations. A big part of their correct functioning has to do with the correct warehouse layout design, as it determines the flow of materials and goods through the facility and the accuracy and efficiency of order fulfillment.

Let’s dive into the importance of effective warehouse layout and provide tips for an effective design.

Warehouse Layout Design

What is a Warehouse Layout Design?

Warehouse layout design refers to the physical arrangement of a warehouse, including the placement of storage racks, aisles, equipment, and other features within the facility. Effective layout design plays a crucial role in optimizing warehouse processes, from the picking and packing to shipping.

A well-designed warehouse layout helps to optimize the flow of materials and goods through the facility, minimizing the time and effort required to move items, and maximizing the use of available space. This, in turn, can lead to reduced labor costs, improved inventory accuracy, and increased throughout.

Finally, an effective warehouse layout design ensures that the right products are located in the right place, reducing the handling of goods and improving the accuracy of order fulfillment.

The Importance of Warehouse Layout Design: Optimizing Efficiency and Productivity

Warehouse layout design holds immense importance in ensuring the smooth and efficient functioning of a warehouse operation. A well-designed warehouse layout improves operational efficiency, maximizes space utilization, and enhances productivity. It enables streamlined workflows, reduces material handling time, and minimizes the risk of errors or bottlenecks. An effective layout design ensures that products are stored in a logical and systematic manner, allowing for easy retrieval, accurate inventory management, and efficient order fulfillment.

Additionally, a well-planned layout considers factors such as traffic flow, aisle widths, and storage density, optimizing the use of available space and minimizing unnecessary movement. It also takes into account safety regulations and ergonomic considerations, providing a safe and comfortable working environment for warehouse personnel.

A thoughtfully designed warehouse layout can lead to cost savings, improved customer satisfaction, and a competitive advantage in the market. By investing time and resources in warehouse layout design, businesses can optimize their operations, increase efficiency, and ultimately achieve higher levels of success in their supply chain management.

Types of Warehouse Layout Designs

There are several types of warehouse layout ideas and designs that organizations can choose from, depending on their specific needs and requirements. Some of the most common types of layout designs include:

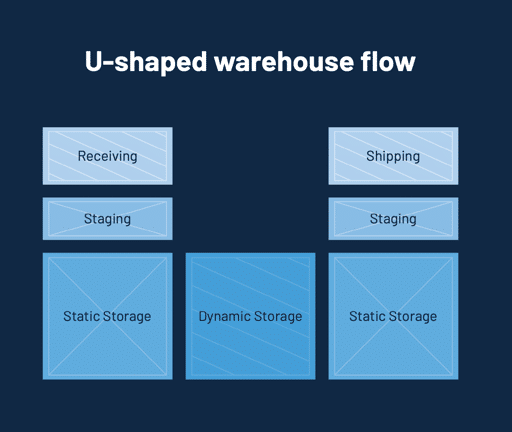

U-Shaped Layout

The U-shaped warehouse layout design is a popular one for beginners as it arranges all components in a semicircle with shipping and receiving on parallel sides and storage in the middle. This helps to streamline traffic flow and avoid bottlenecks by separating incoming and outgoing materials. It also minimizes the necessary space needed for packages and allows for quick movement of products between receiving and shipping.

However, a potential drawback is that production congestion may occur if shipping and receiving areas are too close and share similar domains.

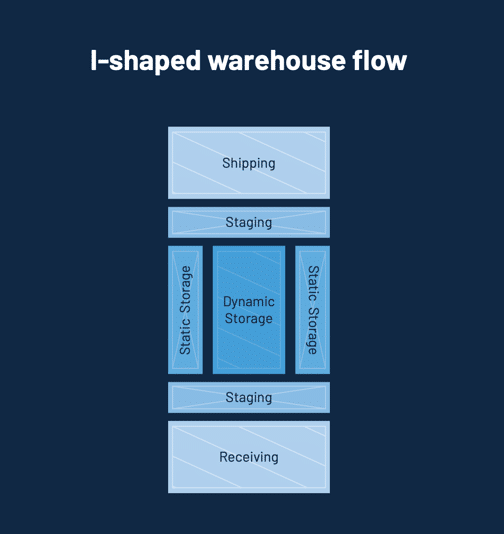

I-Shaped Layout

The I-shaped warehouse layout design is commonly used by larger corporations due to its straight flow from receiving to shipping and vice versa, making it ideal for high production volume. It uses the entire length of the warehouse, keeps similar products separated in an assembly-line format, and minimizes bottlenecks.

On the other hand, this design requires optimal loading and unloading space on two sides of the warehouse building, which may increase costs for docking equipment, and goods may need to travel the entire length of the warehouse.

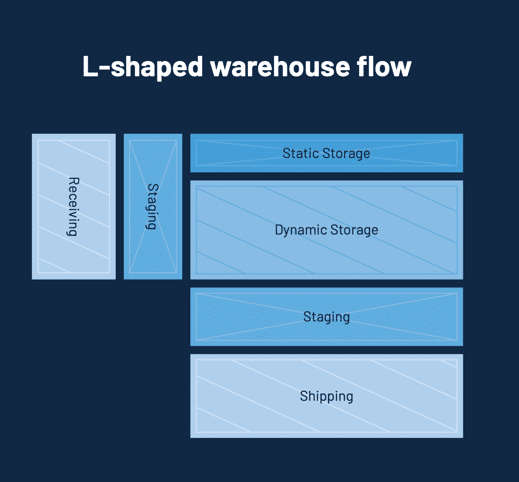

L-Shaped Layout

The L-shaped warehouse layout design is the least commonly used of the three main warehouse flow types. Its layout is typically used for L-shaped buildings. Unlike the U-shape and I-shape flows, the L-shape has the shipping and receiving areas situated at a 90-degree angle. This design allows for an efficient flow of goods and minimizes congestion by separating inbound and outbound docks on opposite sides. It’s worth noting that the L-shaped flow requires more space to operate effectively, which can be a disadvantage.

Choosing the Right Layout Design

Selecting the right warehouse layout design for a warehouse is critical for optimizing processes and improving efficiency. The choice of layout design depends on several factors, including:

- Types of products being stored

- Volume and frequency of material handling activities

- Available space in the warehouse

Let’s see some examples:

U-shaped flow is often used by smaller businesses or those with lower production volume that need a simple, easy-to-navigate warehouse layout. It’s also useful for warehouses with limited space because it requires less square footage. Retailers, wholesalers, and small manufacturers are some examples of businesses that might benefit from a U-shaped flow.

I-shaped flow benefits larger corporations or those with higher production volume because it allows for maximum optimization of warehouse space and efficiency. Manufacturers, distributors, and e-commerce businesses that need to handle a high volume of products could benefit from an I-shaped flow.

L-shaped flow is the least common and is typically used in warehouses that are already L-shaped. Businesses with an existing L-shaped building might choose this layout because it can make the most of the available space. It’s also useful for businesses that need to keep inbound and outbound docks separate, such as those that handle hazardous materials or temperature-sensitive products.

Remember, while these examples can be helpful in choosing a warehouse design, it’s important to evaluate your specific business needs before making a decision. You should consider also implementing a warehouse system if you haven’t to maximize warehouse efficiency.

4 Tips for Designing an Efficient Warehouse Layout

1) Consider the Essential Requirements for a Well-Designed Warehouse

When designing a warehouse layout, it’s crucial to ensure that the facility can cover the following needs:

- Making the most of the available space: This is essential as it directly impacts storage capacity and the overall efficiency of the warehouse.

- Reducing the handling of goods to a minimum: This minimizes the risk of product damage and maximizes productivity by reducing the time and effort required to move items.

- Providing easy access to the stored product: Easy access to the products in the warehouse is essential to ensure smooth operations and timely order fulfillment.

- Having the highest rotation ratio possible: The layout should allow for the highest possible turnover rate of products, reducing inventory holding costs and ensuring that products are not kept in storage for longer than necessary.

For businesses maintaining warehouse documentation or needing high-quality visuals in their facility layouts, showcasing details with crystal-clear imagery can make a significant difference. If your product photos or layout images turn out less than perfect, you can easily fix blurry pictures using online AI-powered tools. These enhance image quality, correct colors, sharpen details, and help present professional-looking visuals for audits or presentations. - Offering maximum flexibility in the positioning of products: The layout should be flexible enough to allow for the repositioning of products as needed, without disrupting the overall flow of materials through the facility.

- Controlling the amounts stored: The layout should help control inventory levels and ensure that the right amount of products is kept in stock, reducing the risk of overstocking or stockouts.

2) Prioritize Safety and Ergonomics

Another crucial aspect of an efficient warehouse layout design is prioritizing the safety and ergonomics of workers. This can be achieved by implementing the following:

- Providing clear markings and signage to help workers navigate the warehouse safely, reducing the risk of accidents.

- Ensuring that aisles and walkways are wide enough for workers and equipment to pass through safely, preventing collisions and other hazards.

- Providing ergonomic equipment, such as lift trucks or conveyor belts, to minimize the risk of injuries and improve productivity by reducing physical strain on workers.

3) Optimize Your Storage System

To maximize the efficiency of your warehouse, it’s essential to optimize your storage system. This can be achieved by:

- Using appropriate storage equipment, such as pallet racks, shelving, or mezzanine systems.

- Grouping similar products together to minimize the need for product handling and improve picking efficiency.

- Implementing a system for tracking inventory levels such as a WMS system, can ensure that products are stored and picked efficiently

4) Continuously Monitor and Improve Your Layout

This is crucial for ensuring its efficiency over time. This can be done by:

- Conducting regular audits of the warehouse layout design to identify areas for improvement,

- Soliciting feedback from workers and managers to identify opportunities for optimizing processes.

- Staying up-to-date with industry trends and best practices to identify new ways to improve the efficiency of your warehouse.

By continuously monitoring and improving your layout, you can ensure that your warehouse remains efficient and effective in meeting the needs of your organization.

Maximizing Efficiency: Innovative Warehouse Layout Ideas

When it comes to optimizing warehouse operations, the layout plays a crucial role in streamlining processes and maximizing efficiency. Implementing innovative warehouse layout ideas can greatly enhance productivity, reduce errors, and improve overall workflow. One such concept is the “cross-docking” layout, where products are quickly transferred from inbound to outbound docks, minimizing storage time and expediting order fulfillment. Another effective approach is the “zone picking” layout, where the warehouse is divided into distinct zones based on product types or order priorities, enabling faster and more organized picking operations.

Additionally, incorporating automation and robotics into the layout design can revolutionize warehouse operations, with intelligent conveyor systems and automated storage and retrieval systems (AS/RS) optimizing space utilization and expediting order processing. By embracing these creative warehouse layout ideas, businesses can achieve greater efficiency, lower costs, and elevate customer satisfaction to new heights.

Warehouse Layout Ideas: Maximizing Efficiency and Optimization

Warehouse layout plays a critical role in the overall efficiency and productivity of a warehouse operation. A well-designed warehouse layout improves inventory management, order fulfillment, and overall operational flow. Ideas such as implementing a logical product placement strategy, utilizing vertical space with mezzanine levels or high shelves, and incorporating automation technologies can significantly enhance productivity and minimize travel distances.

Additionally, employing a systematic zoning approach, with dedicated areas for receiving, picking, packing, and shipping, can improve process efficiency and reduce errors. Furthermore, optimizing the layout to ensure smooth traffic flow, clear signage, and ergonomic workstations can enhance employee safety and comfort, leading to increased productivity and job satisfaction. By incorporating creative and intelligent warehouse layout ideas, businesses can maximize space utilization, minimize operational bottlenecks, and achieve greater efficiency in their warehouse operations.

In Conclusion

Effective warehouse layout design can help organizations achieve a well-organized and streamlined facility that enables goods to move quickly and efficiently, which leads to increased productivity, and ultimately, satisfied customers. However, it’s essential to recognize that the success of a warehouse depends on a combination of factors, including efficient inventory management, order processing, and delivery. That’s why organizations need to prioritize fluid order-taking processes, by implementing tools like a DSD software or a DSD route accounting software alongside effective warehouse layout design, to achieve maximum efficiency in their supply chain operations.

Orders In Seconds (OIS) can help organizations optimize their order-taking processes through OIS Pro App. This solution enables businesses to process orders quickly and accurately. By combining effective warehouse layout design with tools like OIS, businesses can achieve a comprehensive solution that optimizes their entire supply chain. If you want to know more about OIS solutions, book a free demo today!

Optimizing Warehouse Layout: Enhancing Efficiency and Productivity

A well-designed warehouse layout plays a pivotal role in streamlining operations and maximizing productivity within a distribution center. From the strategic arrangement of storage racks to the thoughtful positioning of packing stations, the layout directly impacts how goods flow through the facility. An efficiently planned warehouse layout minimizes travel distances, reduces handling times, and ensures easy access to inventory. By integrating advanced technologies such as automated storage and retrieval systems (AS/RS) and data-driven analytics, modern warehouse layouts aim to harmonize storage capacity with operational agility. This results in shorter order fulfillment cycles, reduced operational costs, and an overall improved customer experience. As the logistics landscape evolves, businesses are increasingly recognizing the significance of an optimized warehouse layout as a competitive advantage in meeting the demands of an ever-changing market.

7 Steps to Become a Wholesale Distributor