In today’s fast-paced business world, efficient inventory management is crucial for staying ahead of the competition. A barcode inventory system has revolutionized the way businesses track and manage their inventory, leading to significant improvements in efficiency, accuracy, and cost savings. Are you ready to discover how this barcode inventory system works and how it can revolutionize your business operations?

Key Takeaways

- The Barcode Inventory System is a useful tool for businesses to track and manage inventory efficiently.

- Core elements of the system include barcode labels, scanners, and inventory management software.

- Benefits of implementing a barcode system include increased efficiency, improved tracking & real-time visibility enabling better decision making & business growth.

Table of Contents

- Decoding the Barcode Inventory System

- Types of Barcodes

- Unveiling the Core Elements of a Barcode System

- Charting the Advantages of Barcode Inventory Management Systems

- Implementing Your Barcode Inventory System: A Step-by-Step Guide

- Streamlining Operations: Integrating Barcode Systems with Business Processes

- Navigating Challenges: Overcoming Common Hurdles in Barcode Inventory Management

- Real-World Applications: Barcode Inventory Systems Across Industries

- Summary

- Frequently Asked Questions

- Exploring Inventory Best Practices through Order In Seconds

Barcode Inventory System: A Comprehensive Overview

A barcode inventory system is a technology-driven approach to managing inventory that utilizes barcodes to track and monitor products. It’s a powerful tool that streamlines operations, reduces errors, and improves overall efficiency.

How a Barcode Inventory System Works

- Barcode Creation: Unique barcodes are assigned to each product or product category.

- Barcode Scanning: A barcode scanner reads the barcode, capturing the product’s information.

- Data Processing: The scanned data is transmitted to a computer system, where it’s processed and stored in a database.

- Inventory Management: The system updates inventory levels, tracks product movement, and generates real-time reports.

- Decision Making: The system provides valuable insights to help businesses make informed decisions, such as reordering stock or optimizing inventory levels.

Key Benefits of a Barcode Inventory System

- Accuracy: Reduces human error in inventory counting and data entry.

- Efficiency: Streamlines inventory processes, saving time and labor costs.

- Real-Time Visibility: Provides up-to-date information on inventory levels.

- Better Stock Control: Helps prevent stockouts and overstocking.

- Improved Decision Making: Supports data-driven decisions for optimal inventory management.

- Enhanced Customer Service: Enables faster checkout and reduces wait times.

Essential Components of a Barcode Inventory System

- Barcode Scanners: Devices used to read barcodes.

- Barcode Labels: Labels with barcodes attached to products.

- Inventory Management Software: Software to manage inventory data and generate reports.

- Computer Hardware: Computers and servers to run the software.

- Barcode Printers: Devices to print barcode labels.

Barcode Inventory Software: A Closer Look

Barcode inventory software is the core component of a barcode inventory system. It offers a range of features to help businesses manage their inventory effectively:

- Product Catalog Management: Create and manage a comprehensive product catalog.

- Inventory Tracking: Monitor stock levels, track product movement, and set reorder points.

- Purchase Order Management: Create and manage purchase orders.

- Sales Order Processing: Process sales orders and generate invoices.

- Reporting and Analytics: Generate insightful reports on inventory performance, sales trends, and more.

- Integration with Other Systems: Integrate with point-of-sale (POS) systems, accounting software, and other business applications.

By implementing a robust barcode inventory system, businesses can achieve greater efficiency, accuracy, and profitability.

Avoid the Top 5 Mistakes Wholesale Distributors Make

Types of Barcodes

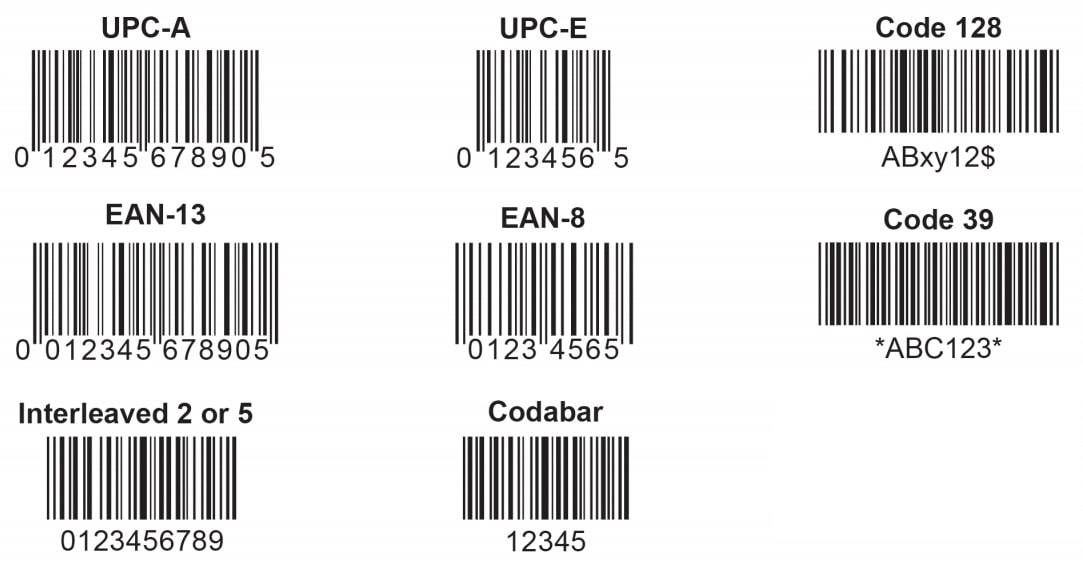

1D barcodes are the traditional linear barcodes that represent data in a series of parallel lines of varying widths, while 2D barcodes, such as QR codes, store information in a matrix of patterns and can hold significantly more data. Both types of barcodes can be easily scanned and decoded using barcode scanners, making them an essential component of any modern inventory management system.

Linear Barcodes

Linear barcodes are the most common type of barcode. They consist of a series of parallel lines of varying widths that encode data. Linear barcodes can only store a limited amount of data, typically a product’s ID number.

- UPC: The Universal Product Code (UPC) is a type of linear barcode that is used to identify products in North America and Canada. UPC barcodes are 12 digits long.

- EAN: The European Article Number (EAN) is a type of linear barcode that is used to identify products in Europe and other parts of the world. EAN barcodes are 13 digits long.

- Code 39: Code 39 is a type of linear barcode that is used to encode alphanumeric data. Code 39 barcodes are often used in industrial and manufacturing applications.

- Code 128: Code 128 is a type of linear barcode that is used to encode alphanumeric data and extended ASCII characters. Code 128 barcodes are often used in logistics and shipping applications.

- Interleaved 2 of 5: Interleaved 2 of 5 is a type of linear barcode that is used to encode numeric data. Interleaved 2 of 5 barcodes are often used in warehouse and distribution applications.

- Codabar: A barcode that is internally created and used within an organization to identify and track items. Internal barcodes are not standardized and can vary in format and encoding.

Two-dimensional Barcodes

Two-dimensional barcodes are a newer type of barcode that can store more data than linear barcodes. Two-dimensional barcodes typically consist of a matrix of black and white squares or dots.

- QR Codes: QR Codes are a type of two-dimensional barcode that can encode alphanumeric data, URLs, and other types of data. QR Codes are often used in marketing and advertising.

- Data Matrix: Data Matrix is a type of two-dimensional barcode that is often used in industrial and manufacturing applications. Data Matrix barcodes are known for their durability and reliability.

- PDF417: PDF417 is a type of two-dimensional barcode that is often used in government and healthcare applications. PDF417 barcodes can store large amounts of data.

- Aztec Code: Aztec Code is a type of two-dimensional barcode that is often used in mobile applications. Aztec Code barcodes are known for their speed and accuracy.

Unveiling the Core Elements of a Barcode System

A successful barcode inventory system hinges on three core components: barcode labels, barcode scanners, and inventory management software. Each component plays a vital role in ensuring the system operates effectively and efficiently.

Let’s delve deeper into these components to better understand their significance.

The Role of Barcode Labels

Barcode labels visually represent crucial product details like:

- Price

- Size

- Color

- Other characteristics as determined by the retailer

These labels are generated using a barcode generator and affixed to individual products, enabling them to be scanned with the point-of-sale (POS) system when they are sold or returned, thereby updating inventory levels.

While Universal Product Codes (UPC) are standardized and issued by the Global Standards Organization, Stock Keeping Unit (SKU) codes are unique to individual retailers and provide more specific information about a product. This distinction allows for efficient tracking and management of inventory levels, ensuring accuracy and optimal performance.

Scanning Barcodes: The Barcode Scanner at Work

Barcode scanners are indispensable devices in a barcode inventory system, as they read the pattern of black and white bars on a barcode and translate it into a series of binary digits, which are then transmitted to a computer for decoding. Barcode scanners come in different forms, such as handheld, presentation, and in-counter scanners, each with its own advantages and ideal use cases.

By automating data input and reducing the need for manual data entry, barcode scanners offer several benefits for inventory management processes. Some of these benefits include:

- Increased speed and accuracy in scanning barcodes

- Improved efficiency in tracking and managing inventory

- Reduced errors and discrepancies in inventory records

- Streamlined workflows and reduced labor costs

The choice of scanner depends on factors such as the type of barcode being scanned, the environmental conditions, and the desired level of mobility. It is essential to select the right scanner for your specific needs to maximize the benefits and effectiveness of barcode scanning in your inventory management system.

Crucial to any successful barcode inventory system, inventory management software processes the information gathered by barcode scanners, enabling real-time inventory tracking and regulation. To effectively track inventory, there are various software options available, from point-of-sale (POS) systems like Lightspeed Retail, Square, and Shopify, to dedicated inventory management programs such as inFlow, TranZact, and Fishbowl.

When selecting the right software for your barcode inventory system, it is important to consider the features it offers, such as:

- Real-time inventory tracking

- Cloud-based storage

- Consolidated inventory management

- Reporting and analytics capabilities

You should also consider its compatibility with your existing systems and hardware. This ensures a seamless integration and maximizes the benefits of your barcode inventory system.

Barcode Inventory: Enhancing Accuracy and Efficiency

Implementing a barcode inventory system brings significant improvements to the accuracy and efficiency of inventory management. Each item in inventory is assigned a unique barcode, which can be scanned to instantly retrieve information such as product ID, price, and stock levels. This eliminates the need for manual data entry, reducing the likelihood of errors and ensuring that inventory records are always up-to-date. Barcoding also speeds up processes such as stocktaking, order fulfillment, and receiving, making it easier for businesses to maintain optimal inventory levels and improve overall operational efficiency.

Charting the Advantages of Barcode Inventory Management Systems

The adoption of a barcode inventory system provides businesses with numerous advantages including reduced odds of misplacing products, real-time inventory analysis, and enhanced efficiency. One-dimensional barcodes, for instance, can be scanned rapidly and precisely, making them suitable for automating inventory processes. Moreover, they can capture additional data, such as expiration dates or batch numbers, facilitating efficient product tracking throughout their lifecycle.

In addition to improving efficiency, barcode inventory systems can also help businesses in the following ways:

- Maintain inventory levels across multiple locations, ensuring that any personnel within the company are aware of stock levels at any given location

- Provide real-time visibility into inventory levels, allowing for better decision-making

- Support business growth

Though the establishment of a barcode inventory system may appear overwhelming, a practical step-by-step approach can make it a seamless and fulfilling process. Here are the steps to implement a barcode inventory system:

- Select the right software and hardware for your needs.

- Generate barcodes for your inventory items.

- Train your staff on how to use the barcode system.

- Start scanning and tracking your inventory using the barcodes.

- Regularly update and maintain your barcode system to ensure accuracy and efficiency.

Implementing a barcode inventory system is an investment that will pay off in the long run, as you’ll see how the barcode inventory system works and enhances efficiency in managing your physical inventory.

Selecting the optimal inventory management software for your business necessitates a comprehensive assessment of your needs, goals, and the software’s features, and related costs. Some popular inventory management software options include:

- Cin7

- Ordoro

- Katana

- Zoho

- NetSuite

These solutions offer various features, such as improved tracking of inventory, data generation and automation of tasks, accelerated shipping and receiving of goods, and integration with other warehouse management systems.

When evaluating the software options, it’s crucial to consider factors such as:

- Real-time inventory tracking

- Cloud-based storage

- Consolidated inventory management

- Tagging and barcoding

- Reporting and analytics

- Forecasting capabilities

- Alerts and notifications

- Centralized inventory management

By selecting a robust system that aligns with your business goals, you can ensure seamless integration and maximize the benefits of your barcode inventory system.

Barcode Inventory Software: The Digital Backbone of Inventory Management

Barcode inventory software is a critical component of any barcode inventory system, enabling businesses to effectively track and manage their stock. This software integrates with barcode scanners and other hardware to automate the collection and recording of inventory data. Features of barcode inventory software typically include real-time inventory tracking, automated stock alerts, reporting tools, and integration with other business systems such as accounting and order management. By centralizing inventory data, this software provides valuable insights that help businesses make informed decisions, optimize stock levels, and enhance supply chain efficiency.

Choosing suitable hardware like barcode scanners and printers, is as crucial to your barcode inventory system as the selection of the appropriate software. Factors to consider include the type of barcode scanner (portable or fixed), the type of barcode to be scanned, and the environmental conditions of scanner use. Some top-rated barcode scanners for inventory management include Honeywell 1900G-SR 2D Barcode Scanner with USB Cable, Datalogic Gryphon GM4430-BK 2D Cordless Barcode Scanner, Zebra TC52x Series, Honeywell Granit 1981i, Datalogic Memor 20, Symbol CS4070-HC, and Opticon OPN-3002i.

Barcode printers are another essential piece of hardware for barcode inventory systems. These specialized devices generate barcode labels to be affixed to physical objects, with features such as:

- The capacity to print labels for various applications like inventory control, product labeling, and shipping

- Compatibility with your chosen software solution

- Seamless integration with your barcode inventory system

- Enhanced efficiency

By investing in quality hardware that meets these criteria, you can ensure a seamless integration and enhance the efficiency of your barcode inventory system.

Generating barcodes for your inventory items represents an essential step in establishing your barcode inventory system. Depending on your needs, you can choose between one-dimensional and two-dimensional barcodes, each with its own advantages and capacity to store information. For example, 1D barcodes can store fewer than 100 characters, while 2D Data Matrix barcodes can encode up to 1,500 characters. Scanning accuracy and speed is improved when the character count is limited to 800 or fewer. It is therefore advised to use this limit for best results..

To create a barcode and generate barcode labels, you can use a barcode generator or an online tool, such as the SOS Inventory barcode template. Once the barcodes are generated, they can be printed and affixed to your inventory items, allowing for efficient tracking and management of stock levels.

Barcoding Software for Inventory: Choosing the Right Solution

Selecting the right barcoding software for inventory is essential for ensuring that your barcode inventory system operates smoothly and efficiently. The best software solutions offer robust features such as easy integration with existing systems, customizable reporting, and support for various barcode types. Additionally, the software should be user-friendly, scalable to grow with your business, and capable of handling large volumes of inventory data. When choosing barcoding software, it’s important to consider your specific needs, such as the type of inventory you manage, the size of your warehouse, and your business processes.

Incorporating barcode inventory systems into current business processes can notably enhance the efficiency and potency of your operations. Some benefits of using barcode systems include:

- Monitoring inventory levels in real-time

- Maintaining inventory levels and sales

- Boosting productivity

- Improving efficiency and cost-effectiveness

- Enabling product tracking

By embracing barcode technology, businesses can optimize their operations and stay competitive in today’s rapidly evolving market.

To ensure a successful integration, it’s essential to:

- Digitize internal processes with barcode scanning software

- Integrate barcoding with other warehouse management systems

- Analyze your warehouse needs and select appropriate label technology

- Ensure compatibility with existing systems

- Evaluate effective barcoding practices

- Implement visual manufacturing barcodes to enhance efficiency in manufacturing processes

By following these best practices, your business can reap the benefits of a streamlined barcode inventory system.

If tackling issues related to sales and efficiency is at the forefront of your business goals, our ebook ‘B2B Wholesale Distributors: 5 Step Guide to Doubling Your Sales Order’ offers invaluable insights. Dive into the best practices outlined in this comprehensive guide to enhance your operations and achieve a competitive edge.

Double Your Sales Orders in 5 Steps

This exclusive eBook is packed with real-world, data-driven concepts that can help maximize your store visits and double your sales. Get it for FREE – Today!

Establishing a barcode inventory system can present its unique challenges, including:

- Printing problems

- Human error

- Lengthy stock counts

- Insufficient system setup

- High setup and maintenance costs

- Issues integrating barcodes into current workflows

However, these challenges can be overcome with careful planning and strategic problem-solving.

To effectively address these difficulties, invest in quality hardware, train staff on the correct use of the system, and routinely review and update the system to guarantee accuracy and efficiency. By proactively addressing potential issues and implementing solutions, your business can enjoy the benefits of a barcode inventory system while minimizing challenges.

How a Barcode Inventory System Works: Streamlining Stock Management

Understanding how a barcode inventory system works is key to realizing its benefits. The system operates by assigning a unique barcode to each product, which is then scanned whenever the item is moved, sold, or received. The barcode scanner reads the encoded information and transmits it to the inventory management software, which updates the stock levels in real-time. This process eliminates manual entry, reduces errors, and ensures that inventory data is accurate and current. By providing a clear, real-time view of inventory status, a barcode inventory system helps businesses maintain optimal stock levels, prevent stockouts, and improve overall operational efficiency.

Across various industries such as retail, manufacturing, healthcare, logistics and warehousing, food and beverage, and field service, barcode inventory systems have demonstrated their value. In the retail industry, for example, barcode inventory management systems provide real-time inventory tracking, record inventory levels and sales, optimize productivity, enhance efficiency and cost-effectiveness, and enable product tracking.

In the medical field, barcode inventory systems have been utilized to improve patient safety, streamline processes, and accurately track medication. These real-world applications demonstrate the immense value that barcode inventory systems can bring to businesses across various sectors, highlighting their potential to revolutionize inventory management and streamline operations.

Embracing barcode inventory systems can greatly enhance the efficiency, accuracy, and cost-effectiveness of your business operations. By understanding the components, benefits, and challenges of implementing such a system, as well as exploring real-world applications across industries, you can equip your business with the tools necessary to stay competitive and thrive in today’s fast-paced market. Don’t let outdated inventory management practices hold your business back – invest in a barcode inventory system and watch your operations soar.

Frequently Asked Questions

Creating a barcode inventory system requires identifying industry standards, defining barcode functions, choosing barcode information, selecting software and hardware, and implementing barcode inventory procedures. Finally, set up the system by defining SKUs, choosing an inventory software system, creating the barcodes, updating the inventory management system, and putting barcoding inventory in place.

Does Quickbooks inventory use barcodes?

Yes, QuickBooks Enterprise includes a feature that allows Android devices to be turned into mobile barcode scanners. This allows users to manage each inventory item more efficiently and obtain real-time inventory data across their business.

What is the best barcode for inventory management?

For inventory management, Code 39 and Code 128 barcodes with simple alphanumeric formats are the best options, especially for smaller items.

How to make a barcode?

Select a barcode type, fill in product category information, and add a name and optional notes. Then, click ‘Generate’ to receive a high-resolution barcode via email.

What is the difference between UPC and SKU codes?

UPC codes are universal identifiers used to identify products in stores worldwide, while SKU codes are unique to each retailer and contain more specific product details.

Exploring Inventory Best Practices through Order In Seconds

Incorporating barcode scanning for inventory management is a smart move; however, it’s crucial to implement best practices for inventory right from the beginning, especially when placing orders. With Order In Seconds (OIS), this process becomes a breeze. The OIS Pro App empowers field sales reps with real-time inventory visibility, ensuring they never place orders for items that are out of stock. Make sure you’re giving attention to inventory management from the start, and let OIS simplify the process for you.

If you’re ready to explore this solution, you can schedule a demo with us today!