Effective inventory management can reduce wastage by up to 35% and prevent stockouts by 50%, directly impacting your bottom line. If you’ve ever wondered how retail stores manage thousands of products efficiently, the answer lies in a simple but powerful system: Stock Keeping Units.

Whether you’re running an online store, managing a retail business, or working in supply chain operations, understanding what a SKU is and how to implement an effective sku system is crucial for both online business and retail store operations. Proper SKU management enhances inventory accuracy, improves customer experience, and streamlines product organization in both eCommerce and physical retail environments.

In this comprehensive guide, we’ll explore everything you need to know about stock keeping units, from basic definitions to advanced implementation strategies that help businesses streamline inventory management and optimize sales performance.

Key Takeaways

A SKU (Stock Keeping Unit) is a unique alphanumeric code assigned by retailers to identify and track products in their inventory system

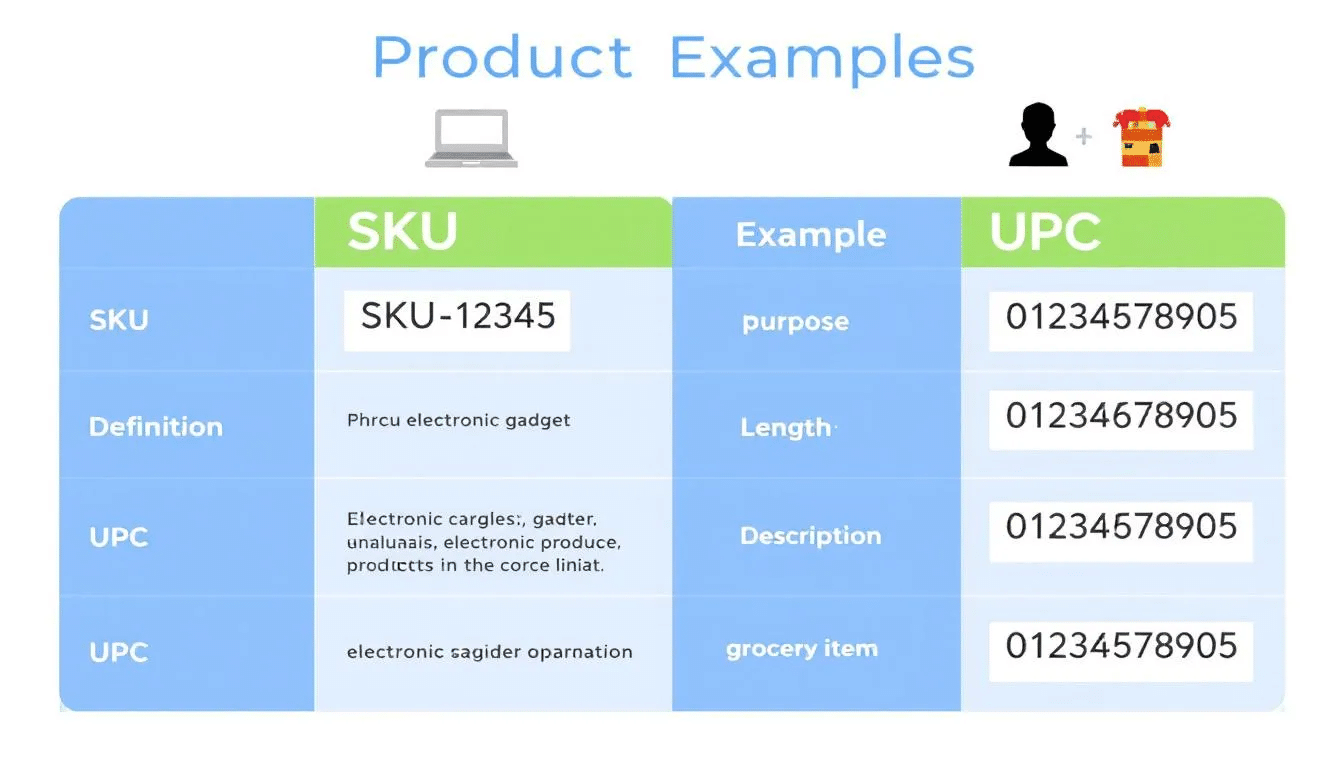

- SKUs are different from UPC codes - while UPCs are universal, SKUs are created internally by each business to track their specific inventory needs

- Effective SKU management improves inventory accuracy, reduces costs, and enhances customer experience through better stock tracking

- SKUs typically contain 8-12 characters encoding product attributes like category, size, color, and brand for easy identification

- Implementing a structured SKU system supports automated inventory management, demand forecasting, and sales analytics

Table of Contents

- What is a SKU (Stock Keeping Unit)

- How SKUs Work in Business Operations

- Benefits of Using SKUs

- SKU vs Other Product Identification Codes

- How to Create Effective SKUs

- Best Practices for SKU Management

- SKU Stand and Organization

- SKU Examples by Industry

- Common SKU Management Mistakes

- Technology and SKU Management

- Frequently Asked Questions

- Smarter Inventory Starts with Smarter Operations

What is a SKU (Stock Keeping Unit)

A Stock Keeping Unit is a unique identifier assigned to each product or product variant in a retailer’s inventory system (SKU stands for Stock Keeping Unit). This alphanumeric SKU code serves as the backbone of modern inventory management, enabling businesses to track inventory levels, monitor sales performance, and manage stock efficiently across multiple locations and sales channels.

The SKU code format usually consists of 8-12 alphanumeric characters representing specific product characteristics. Unlike universal product codes that remain consistent across all retailers, each business creates their own SKUs tailored to their specific operational needs and product catalog structure. Developing an own SKU system is important for internal inventory management, offering flexibility and compatibility with external systems. Each retailer creates their own SKU to uniquely identify and organize products.

Every product variation receives its own unique SKU number. For example, a red, medium t-shirt might have SKU code “TSH-RED-M-001” while a blue, large version of the same product gets “TSH-BLU-L-001”. This granular approach allows retailers to track exactly which product variants are selling well and which need attention.

The primary purpose of a SKU stock keeping unit is to enable accurate inventory tracking and provide detailed sales data for business decision-making. SKUs are used to track inventory, sales, and product movement, similar to how UPCs and serial numbers are used to track products, but SKUs are designed for internal management and organization. When implemented correctly, SKU codes become essential tools for managing inventory across physical stores, warehouses, and online platforms.

Consider how a typical SKU represents multiple product attributes within its structure. A SKU reflects key product characteristics by embedding important attributes such as color, manufacturer, size, and model into the SKU code. A clothing retailer might use “TOP-WOM-BLU-M-CTN” to indicate tops, women’s clothing, blue color, medium size, and cotton material. This encoding system allows staff to quickly identify products without referring to lengthy descriptions or product databases.

Avoid the Top 5 Mistakes Wholesale Distributors Make

How SKUs Work in Business Operations

SKUs function as the central nervous system of modern retail operations, connecting various business processes through a unified identification system. Retailers rely on SKUs for efficient inventory management and sales tracking. Understanding how stock keeping units integrate with daily operations helps businesses maximize their inventory management potential.

Inventory Tracking and Management

Retail stores use sku data to maintain real-time visibility of stock levels across multiple locations. When a customer purchases a product, the pos system automatically updates inventory levels using the product sku, ensuring accurate inventory tracking without manual intervention. This automation helps prevent overselling and enables businesses to track inventory movement patterns.

Assigning SKUs to products is a crucial step during inventory setup, allowing each item to be uniquely identified and tracked throughout its lifecycle. Inventory management systems rely on unique skus to organize stock efficiently. Using SKU numbers helps keep inventory organized, making it easier to locate and manage products. Warehouse workers can locate specific items quickly using sku codes, reducing fulfillment time and minimizing picking errors. For businesses managing inventory across multiple locations, skus enable centralized monitoring of stock levels and automated stock replenishment when quantities fall below predetermined thresholds.

Sales Analysis and Performance Tracking

Sales data collected at the sku level provides invaluable insights into customer preferences and product performance. Integrating inventory and sales data is essential for improved SKU management and informed decision-making regarding reordering, discounts, and inventory allocation. Businesses can analyze which specific product variants generate the highest revenue, identify sales trends by season or location, and make data-driven decisions about future inventory purchases.

Ecommerce sellers particularly benefit from detailed sku tracking, as online platforms generate comprehensive sales performance reports based on individual product skus. This granular data helps online retailers optimize their product mix and identify opportunities for expansion or consolidation.

Order Fulfillment and Customer Service

When customers place orders, fulfillment teams use sku numbers to locate and pick the correct items from warehouse locations. This system reduces errors significantly compared to manual product identification methods, improving customer satisfaction through accurate order delivery.

Customer service teams can quickly identify products and check availability using sku codes, enabling them to provide immediate assistance with product inquiries, returns, and exchanges. The standardized identification system ensures consistent communication between different departments and locations.

Benefits of Using SKUs

Implementing a comprehensive sku management system delivers measurable improvements across multiple business areas. Research shows that well-structured stock keeping unit systems can reduce inventory wastage by 10-35% and decrease out-of-stock incidents by up to 50%.

Enhanced Inventory Accuracy

Accurate inventory tracking becomes achievable when each product variant has its own unique sku. Businesses report up to 25% reduction in counting errors and phantom inventory issues after implementing systematic sku codes. This accuracy improvement directly translates to better demand forecasting and more reliable stock replenishment processes. Analyzing SKU-level data also enables businesses to forecast future sales and demand, supporting more precise inventory planning and personalized product recommendations.

Physical inventory counts become more efficient and reliable when staff can scan sku barcodes instead of manually identifying products. The standardized approach reduces human error and enables faster cycle counting procedures.

Improved Operational Efficiency

Streamlined inventory management occurs naturally when businesses adopt consistent sku formats across their product catalog. Warehouse operations benefit from faster product identification, reduced training time for new employees, and improved picking accuracy.

Online retailers experience significant efficiency gains through automated inventory updates and simplified product catalog management. When inventory management software automatically tracks sales and adjusts stock levels based on sku data, businesses can focus resources on strategic activities rather than manual inventory tasks. For small businesses, manual sku management can be both a challenge and a benefit—while it requires more hands-on effort to assign and track SKUs, it allows for detailed analysis of SKU and sales ratios to optimize inventory and product performance.

Cost Reduction and Profitability

Effective sku systems help identify slow-moving inventory before it becomes obsolete, enabling businesses to implement promotional strategies or liquidation plans proactively. This approach prevents excessive carrying costs and reduces write-offs of unsold merchandise.

Demand forecasting becomes more accurate when historical sales data is organized by individual product skus. Businesses can optimize their purchasing decisions, reduce excess inventory, and maintain optimal stock levels that balance customer demand with carrying costs.

Enhanced Customer Experience

Customer satisfaction improves significantly when businesses can provide accurate product availability information and fulfill orders correctly. The reliability of sku-based inventory systems enables online stores to offer real-time stock status and prevents disappointing customers with out-of-stock notifications after purchase.

Retail stores benefit from improved product organization and faster customer service response times when staff can quickly locate products using sku codes. This efficiency translates to shorter wait times and more positive shopping experiences.

Speed Up Your Warehouse Operations

A Simple Guide: How to Label Your Warehouse Bin Locations

SKU vs Other Product Identification Codes

Understanding the differences between various product identification systems helps businesses choose the right approach for their specific needs. While all these systems serve identification purposes, each has distinct characteristics and applications. For example, GTIN codes are typically displayed on product packaging, which aids in product identification and tracking within retail environments.

SKU vs UPC (Universal Product Code)

The fundamental difference between skus and universal product codes lies in their creation and scope. Retailers assign skus internally to track their specific inventory needs, while manufacturers obtain upc codes from external organizations for universal product identification. For insights into how businesses have benefited from efficient inventory tracking, see these testimonials from Orders In Seconds clients.

Universal product codes remain consistent across all retailers selling the same product. For example, a specific Nike shoe model will have the same upc code whether sold at Target, Amazon, or a local shoe store. However, each retailer will assign their own unique sku to track that same product within their inventory system.

Usage and Application

For businesses looking to improve fulfillment accuracy, utilizing warehouse picking software can significantly reduce manual errors and streamline order processing.

Businesses use skus for internal inventory management, sales analysis, and operational efficiency. The same upc might correspond to different skus at various retailers based on their organizational needs and catalog structure.

Point of sale systems typically scan upc codes for product identification during checkout, while inventory management systems use skus for tracking, reporting, and replenishment decisions. Many businesses link their internal sku system with universal product codes to enable seamless integration between sales and inventory processes.

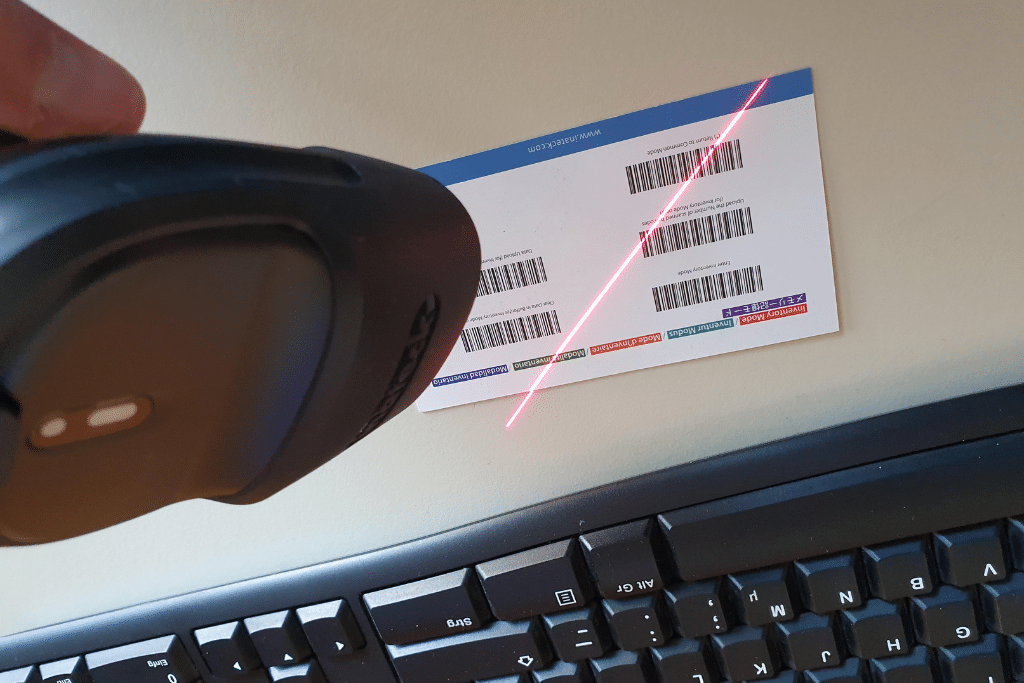

SKU vs Barcode

Barcodes serve as visual representations that can encode various types of data, including sku numbers, universal product codes, or other information. The relationship between skus and barcodes is complementary rather than competitive.

Many businesses create barcodes that represent their internal sku codes, enabling quick scanning and data entry during inventory processes. This approach combines the organizational benefits of custom sku systems with the speed and accuracy of barcode scanning technology.

Practical Implementation

Retail operations often use barcode scanners to input sku data into their pos systems and inventory management software. Staff can scan products to automatically populate sku information, reducing manual entry errors and improving processing speed.

Warehouse management benefits significantly from sku-encoded barcodes, as workers can scan products to instantly access location information, stock levels, and handling instructions associated with specific product skus.

SKU vs Serial Number

While skus identify product types and variants for inventory management purposes, serial numbers track individual units for warranty, service history, and ownership records. This distinction is crucial for businesses selling high-value or regulated products.

One sku might cover multiple identical items in inventory, while each individual unit receives its own unique serial number. For example, all blue 256GB iPhone 14 units might share the same product sku, but each phone has a distinct serial number for warranty and service tracking.

Business Applications

Electronics retailers use both systems complementarily: skus for inventory management and sales tracking, serial numbers for warranty service and theft prevention. This dual approach enables efficient inventory operations while maintaining detailed records for individual product units.

Service businesses benefit from linking sku data with serial numbers to track maintenance history, replacement parts, and customer service interactions for specific units over time.

How to Create Effective SKUs

Creating an effective sku system requires careful planning and consideration of your business’s specific needs. The goal is to develop a logical, scalable structure that supports current operations while accommodating future growth. Generating SKUs systematically is essential to ensure consistency and efficiency in organizing and tracking your inventory.

Planning and Structure Development

Begin by identifying the most important product attributes for your business operations. Consider factors like product category, brand, size, color, material, and any other characteristics that affect inventory decisions or customer preferences.

Develop a hierarchical structure that starts with broad categories and becomes more specific for effective inventory tracking. For example, a clothing retailer might begin with product type (TOP, PANT, SHOE), followed by gender (MEN, WOM), then specific attributes like color and size.

When planning your SKU system, consider the different methods businesses use to generate SKU numbers. Some use automated features within inventory management or point-of-sale systems to generate SKU numbers, while others rely on manual approaches such as spreadsheets for generating SKUs, especially in small businesses.

Character Selection and Format Design

For businesses aiming to enhance efficiency in their order processes, consider using the best B2B ordering app to streamline workflows and empower your team.

Choose characters that are easy to read and won’t cause confusion in your inventory systems. Avoid using characters that look similar, such as 0 and O, 1 and I, or 2 and Z. These similarities can lead to data entry errors and inventory discrepancies.

Keep sku lengths between 8-12 characters for optimal balance between detail and usability. Shorter codes may lack sufficient product detail, while longer codes become cumbersome for manual entry and staff memorization.

SKU Creation Methods

Manual Creation Process

Small businesses can create skus using spreadsheets and predetermined naming conventions. This approach works well for limited product catalogs where consistency can be maintained through careful documentation and staff training.

Manual SKU management involves manually assigning and tracking product SKUs, allowing businesses to closely monitor inventory. This process often includes analyzing SKU and sales ratios to evaluate product performance and optimize inventory levels.

Develop templates for different product categories to ensure consistency. For example, all clothing items might follow the pattern: [TYPE]-[GENDER]-[COLOR]-[SIZE]-[MATERIAL], while electronics follow: [BRAND]-[CATEGORY]-[MODEL]-[SPECIFICATION]. For foodservice products, it’s important to consider customer needs and online ordering efficiency as demonstrated by US Foods’ approach to online ordering and product catalog management.

Automated Generation Systems

Larger businesses benefit from inventory management software that can auto-generate skus based on product attributes. These systems ensure consistency and reduce the time required to assign skus to new products.

Modern ecommerce platforms often include sku generation tools that create codes automatically when products are added to the catalog. This automation reduces errors and ensures all products receive properly formatted identifiers.

Hybrid Approaches

Many successful businesses combine manual oversight with automated tools for optimal results. Key products might receive manually crafted skus for easy recognition, while standard items use automated generation based on established rules.

This approach allows businesses to maintain control over important product categories while benefiting from automation for routine inventory additions.

Best Practices for SKU Management

Implementing effective sku management requires ongoing attention to consistency, documentation, and system integration. Following established best practices helps businesses avoid common pitfalls and maximize the benefits of their stock keeping unit system.

Consistency and Standardization

Maintain the same sku format and logic across all product categories to ensure staff can quickly understand and use the system. When team members can predict sku structure, they make fewer errors and work more efficiently.

Document your sku creation rules clearly and train all relevant staff on proper procedures. This documentation becomes essential when new employees join the team or when expanding product lines require sku assignments.

System Integration and Compatibility

Ensure your sku system works seamlessly with pos systems, inventory management software, and accounting platforms. Test sku formats in all systems before full implementation to identify potential compatibility issues.

Avoid special characters like punctuation marks that might cause problems in certain software systems. Stick to alphanumeric characters that work reliably across different platforms and databases. For more best practice tips and educational resources, check out the Orders in Seconds webinars.

Scalability and Future Planning

Design sku formats to accommodate future product lines and business growth. Consider how your business might expand and ensure your sku structure can handle additional product categories without requiring complete restructuring.

Reserve certain character positions or prefixes for future use, allowing your system to grow organically as your business evolves.

Regular Maintenance and Auditing

Conduct periodic reviews of your sku database to identify and remove duplicate codes, obsolete products, and formatting inconsistencies. Regular audits help maintain data quality and system efficiency.

Establish procedures for handling discontinued products, seasonal items, and limited-time offerings to prevent sku database clutter while preserving important historical data.

Staff Training and Documentation

Create clear guidelines for sku creation and ensure all relevant team members understand proper procedures. Regular training sessions help maintain consistency as your team grows and changes.

Maintain a master document that explains your sku logic, including examples for each product category and procedures for handling special cases or exceptions.

SKU Stand and Organization

A well-structured stock keeping unit (SKU) system is the foundation of accurate inventory tracking and efficient business operations. While a SKU is a unique code assigned to each product variant, the way these codes are organized within your inventory system can make a significant difference in your ability to track inventory and respond to business needs.

Effective SKU management means more than just assigning codes—it’s about creating a logical structure that allows you to quickly locate products, monitor inventory levels, and identify trends in sales and stock movement. When your stock keeping unit sku organization is clear and consistent, it becomes much easier to track inventory levels in real time, reducing the risk of stockouts or overstocking.

Organized SKUs enable businesses to streamline inventory tracking across multiple locations and sales channels. By grouping similar products together and using a consistent SKU format, you can quickly assess which items need replenishment and which are moving slowly. This level of organization supports accurate inventory tracking, helping you make informed decisions about purchasing, promotions, and stock replenishment.

Moreover, a well-organized SKU system directly impacts customer satisfaction. When you can track inventory accurately, you’re less likely to disappoint customers with out-of-stock items or delayed shipments. Fast, reliable access to inventory data means you can fulfill orders promptly and provide up-to-date product availability information, both online and in-store.

In summary, SKU organization is a critical component of effective sku management. By ensuring each sku is a unique and logically structured identifier, businesses can track inventory efficiently, maintain optimal inventory levels, and deliver a superior customer experience. Investing time in organizing your stock keeping unit system pays off in improved operational efficiency and long-term business success.

SKU Examples by Industry

Understanding how different industries implement sku systems provides valuable insights for developing your own approach. Each sector faces unique challenges that influence their stock keeping unit structure and implementation strategies.

Clothing and Fashion Retail

Fashion retailers typically create skus that encode multiple product attributes essential for inventory management. A typical sku structure might look like “TOP-WOM-BLU-M-CTN” representing tops, women’s clothing, blue color, medium size, and cotton material.

Seasonal collections require special consideration in fashion sku systems. Many retailers include season codes or year indicators to distinguish between similar items from different collections, enabling better sales analysis and inventory planning.

Size variations create significant sku complexity in clothing retail. A single shirt design might generate 15-20 different skus when accounting for multiple colors and sizes, requiring careful organization to prevent confusion.

Electronics and Technology

Electronics stores often emphasize brand and technical specifications in their sku formats. A television might use “SAMSG-TV55-4K-BLK” to indicate Samsung brand, 55-inch TV, 4K resolution, and black color.

Technology products frequently require sku updates as manufacturers release new models or discontinue older versions. Effective sku management helps electronics retailers track product lifecycles and plan inventory transitions.

Serial number integration becomes crucial for electronics retailers who need to track individual units for warranty service and theft prevention while using skus for inventory management.

Food and Beverage Industry

Restaurants and food retailers face unique challenges with perishable inventory and expiration dates. SKU systems must accommodate lot tracking and first-in-first-out inventory rotation requirements.

Coffee shops might use sku formats like “ARAB-DARK-12OZ-GRN” for arabica beans, dark roast, 12-ounce package, ground preparation. This structure helps staff quickly identify products and manage inventory rotation.

Seasonal menu items and limited-time offerings require flexible sku assignment procedures that can handle temporary products without disrupting the core inventory system.

Hardware and Construction

Hardware stores manage complex inventories with items that vary by size, material, finish, and packaging quantity. A sku like “SCREW-PH-2IN-25PK” clearly indicates screws, Phillips head, 2-inch length, 25-piece package.

Bulk quantities and unit-of-measure variations create sku complexity in hardware retail. The same product might be sold individually, in small packages, or in contractor-sized quantities, each requiring separate sku tracking.

Compatibility and specification details become critical in hardware sku systems, as customers need precise product information to ensure proper fit and function for their projects.

Common SKU Management Mistakes

Avoiding common pitfalls in sku management saves businesses significant time and resources while preventing operational disruptions. Understanding these mistakes helps organizations implement more effective stock keeping unit systems from the beginning.

Inconsistent Formatting and Structure

One of the most frequent mistakes involves using different sku structures for similar products, creating confusion and operational inefficiency. When team members encounter unexpected formats, they make more errors and require additional training time.

Starting with zeros in sku codes can cause problems in spreadsheets and some inventory systems that automatically remove leading zeros. This formatting issue can create duplicate skus or system conflicts that are difficult to resolve.

Overly Complex or Simple Systems

Creating sku codes that are too long or detailed reduces usability and increases the likelihood of data entry errors. Staff members struggle to remember complex codes, leading to mistakes during manual entry or product identification.

Conversely, overly simple sku systems may lack sufficient detail to support advanced inventory management needs. Finding the right balance requires consideration of current operations and future growth plans.

Poor Documentation and Training

Failing to document sku creation rules leads to inconsistency over time, especially as teams change and businesses grow. Without clear guidelines, different employees may create conflicting sku formats for similar products.

Inadequate staff training on sku procedures results in errors that compound over time, reducing inventory accuracy and creating operational challenges across multiple departments.

Neglecting System Integration

Implementing sku systems without considering compatibility with existing software can create operational bottlenecks and data synchronization problems. Testing sku formats across all business systems before full implementation prevents costly corrections later.

Ignoring the needs of different departments can result in sku systems that work well for inventory management but create problems for sales teams, customer service, or accounting functions.

Inadequate Maintenance Procedures

Allowing obsolete skus to remain active in the system creates clutter and confusion, making it harder for staff to find current products and increasing the risk of ordering discontinued items.

Failing to establish procedures for handling seasonal items, limited editions, and product variations can lead to sku proliferation and database management challenges.

Technology and SKU Management

Modern technology transforms sku management from a manual, error-prone process into an automated, efficient system that supports real-time decision-making and operational excellence. Understanding available tools helps businesses choose the right solutions for their specific needs.

Point of Sale System Integration

Modern pos systems automatically update inventory levels when products are scanned using their sku codes, eliminating manual tracking and reducing errors. This integration provides real-time visibility into sales trends and stock levels across multiple locations.

Cloud-based pos platforms enable businesses to access sku data and inventory information from any location, supporting multi-store operations and mobile sales activities. The centralized approach ensures consistency across all sales channels.

Inventory Management Software Solutions

Specialized inventory management systems offer advanced features like automated reorder points, demand forecasting, and sku performance analytics. These tools help businesses optimize stock levels and reduce carrying costs while maintaining customer satisfaction.

Integration capabilities allow inventory systems to communicate with accounting software, ecommerce platforms, and supplier databases, creating seamless workflows that reduce manual data entry and improve accuracy.

Barcode and Scanning Technology

Modern barcode scanners can quickly input sku data into inventory systems, reducing manual entry time and eliminating transcription errors. Mobile scanning devices enable inventory management from anywhere in the warehouse or retail location.

Advanced scanning systems can read multiple barcode formats and integrate with mobile devices, providing flexibility for businesses with diverse product types and operational requirements.

Analytics and Reporting Tools

Business intelligence platforms analyze sku-level data to identify sales trends, seasonal patterns, and customer preferences. These insights help businesses make informed decisions about inventory purchases, pricing strategies, and product mix optimization.

Real-time dashboards provide immediate visibility into sku performance, enabling quick responses to sales trends and inventory issues before they impact customer satisfaction or profitability.

Cloud-Based Platforms and Mobile Access

Cloud inventory systems enable businesses to manage skus across multiple locations while providing real-time synchronization and backup capabilities. Mobile access allows managers to monitor inventory and sales performance from anywhere.

API integrations connect sku data with ecommerce platforms, marketplaces, and third-party logistics providers, creating unified inventory management across all sales channels and fulfillment options.

The integration of artificial intelligence and machine learning with sku management systems enables predictive analytics, automated reordering, and intelligent demand forecasting that continuously improves inventory optimization.

Frequently Asked Questions

How long should a SKU be?

Most effective skus contain 8-12 characters to balance detail with usability. Shorter skus are easier to remember and input manually but may lack sufficient product detail for complex inventories. Longer skus can include more attributes but become cumbersome for staff to use and remember. The optimal length depends on your product complexity and operational needs – simple retailers might use 6-8 characters while complex manufacturers may need 10-12 characters.

Can I change a SKU after it’s been created?

While technically possible, changing skus should be avoided as it disrupts historical sales data tracking and can cause confusion across multiple systems. SKU changes require updating inventory management systems, pos systems, accounting software, and any integrated platforms. If changes are absolutely necessary, ensure proper data migration procedures and comprehensive staff training on new codes. Consider creating new skus for significant product changes rather than modifying existing ones.

Do I need different SKUs for the same product sold through different channels?

Generally, the same product should use the same sku across all sales channels for consistency and simplified inventory management. This approach enables unified inventory tracking and prevents confusion when managing stock across online stores, physical locations, and third-party marketplaces. Some businesses create channel-specific skus for detailed tracking purposes, but this adds complexity and can create inventory management challenges. Modern inventory systems can track sales by channel without requiring separate skus.

How do SKUs help with tax compliance and accounting?

SKUs enable accurate cost of goods sold (COGS) calculations by tracking specific product costs and margins at the individual item level. Detailed sku records support tax deductions for business expenses, inventory write-offs, and accurate valuation of remaining stock for tax purposes. SKU-level tracking helps businesses comply with sales tax requirements for different product categories and provides auditable records for tax authorities. Many accounting systems integrate with inventory management platforms using sku data for automated financial reporting.

What happens to SKUs when products are discontinued?

Discontinued product skus should be marked as inactive rather than deleted to preserve historical sales data and enable future analysis. Keeping old skus in the system helps with warranty claims, returns processing, and long-term sales trend analysis. Archive obsolete skus in a separate category or database section to avoid confusion with active inventory while maintaining data integrity. This approach supports accurate historical reporting and helps businesses understand product lifecycle patterns for future planning.

Smarter Inventory Starts with Smarter Operations

Managing SKUs is just the start — what really drives growth is how efficiently you handle every order, count, and delivery.

With Orders in Seconds, wholesale distributors get a full suite of tools to manage sales, inventory, and deliveries in one place — keeping teams connected and customers satisfied.

Schedule a demo and learn more!