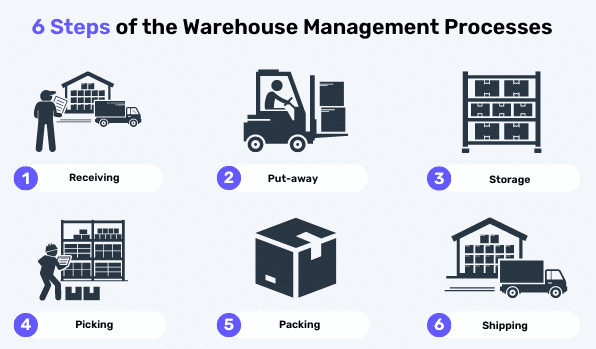

The best Warehouse Management System (WMS) is a comprehensive software solution that enables businesses to optimize their warehouse operations by improving inventory accuracy, reducing labor costs, and enhancing customer service. It should be capable of performing several key functions such as receiving, putaway, picking, packing, shipping, and inventory management, providing real-time visibility into the entire warehouse inventory and operations. The core function of a warehouse management system is to coordinate receiving, storing, picking, packing, and shipping processes, optimizing resources and workflows for efficiency. The system should also have the ability to track and manage inventory at a SKU level, ensuring that the right products are stocked in the right location, at the right time, and in the right quantities.

Cloud based warehouse management is an innovative solution that leverages cloud technology to deliver real-time visibility, scalability, and seamless integration with omnichannel fulfillment, making it ideal for both SMBs and large enterprises in the digital economy. The key benefits of cloud based solutions include predictable costs, scalability, and ease of integration, which support business growth and fluctuating demand.

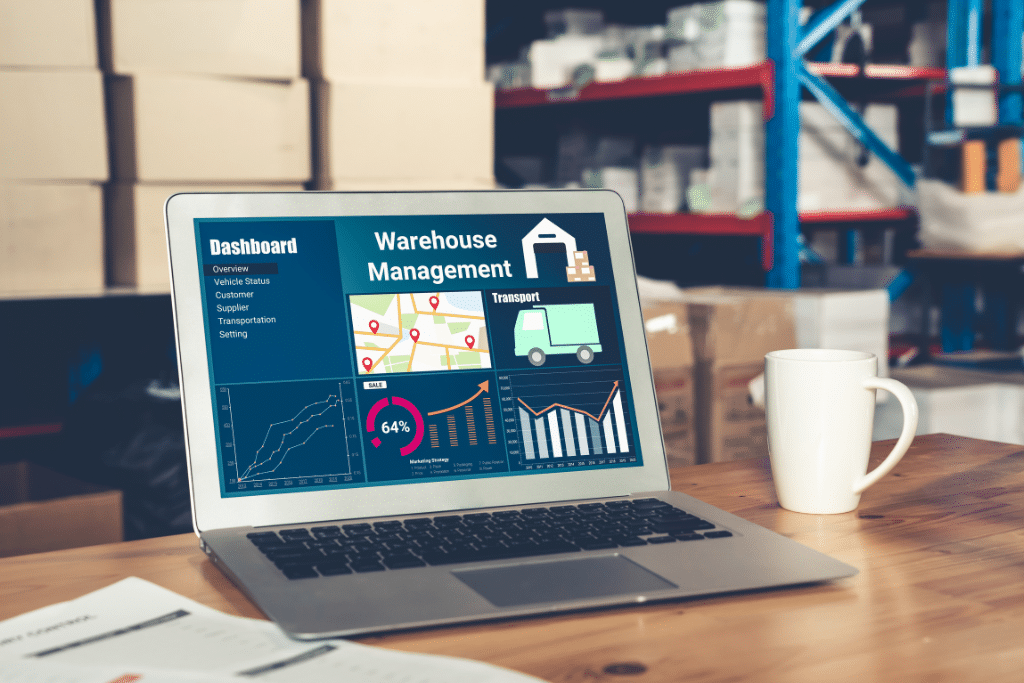

The best Warehouse Management System should have features that enable efficient order fulfillment, such as order processing, order picking, and packing. Compared to on premise solutions—including on premises systems and on premises WMS—cloud based warehouse management offers the advantages of software as a service, lower upfront costs, and rapid deployment. It should be able to integrate with other systems, such as transportation management systems (TMS) and enterprise resource planning (ERP) systems, to ensure that the entire supply chain is optimized for maximum efficiency. Integration capabilities are essential for seamless operations with ERP and supply chain platforms, enhancing operational efficiency, accuracy, and scalability. The system should also provide various reports and dashboards to provide insights into key performance indicators such as inventory accuracy, order fulfillment rates, and warehouse utilization rates.

Another important aspect of the best Warehouse Management System is its ability to automate manual tasks, such as barcode scanning systems and data entry, which can significantly reduce labor costs and improve efficiency. Barcode scanning systems play a crucial role in warehouse automation and inventory accuracy by integrating with RFID and other technologies to reduce errors and support automation strategies. Cloud-based WMS reduces the need for in house IT infrastructure and allows businesses to respond quickly to changing demands. It should be easy to use and configure, with a user-friendly interface that can be customized to meet the specific needs of each warehouse. The best WMS should also be scalable, capable of supporting the growth of the business and adapting to changing business needs over time. Efficient operations are achieved through the integration of technologies like IoT, RFID, and barcode scanning systems, streamlining warehouse activities and enhancing productivity.

Modern WMS are designed specifically to support complex fulfillment operations, optimize fulfillment processes, and streamline order fulfillment processes through automation and real-time inventory data tracking. WMS functionality also includes managing material flows, integrating with multiple systems, and supporting connections with shipping carriers to optimize supply chain operations. Warehouse optimization features in WMS further enhance operational efficiency by improving logistics performance and resource utilization. Additionally, having warehouse management built directly into ERP systems provides seamless integration, shared databases, and streamlined operations for simplicity and consistency across business processes.

Overall, the best Warehouse Management System is one that can deliver operational efficiency, reduce costs, increase accuracy, and improve customer service. It should provide end-to-end visibility and control over the entire supply chain, enabling businesses to stay competitive in today’s fast-paced and ever-changing marketplace. Choosing a modern WMS from leading WMS vendors ensures access to advanced features and the ability to scale as business needs evolve.

The best Warehouse Management System

The best Warehouse Management System should have features that enable efficient order fulfillment, such as order processing, order picking, and packing. It should be able to integrate with other systems, such as transportation management systems (TMS) and enterprise resource planning (ERP) systems, to ensure that the entire supply chain is optimized for maximum efficiency. The system should also provide various reports and dashboards to provide insights into key performance indicators such as inventory accuracy, order fulfillment rates, and warehouse utilization rates.

Another important aspect of the best Warehouse Management System is its ability to automate manual tasks, such as barcode scanning and data entry, which can significantly reduce labor costs and improve efficiency. It should be easy to use and configure, with a user-friendly interface that can be customized to meet the specific needs of each warehouse. The best WMS should also be scalable, capable of supporting the growth of the business and adapting to changing business needs over time.

Overall, the best Warehouse Management System is one that can deliver operational efficiency, reduce costs, increase accuracy, and improve customer service. It should provide end-to-end visibility and control over the entire supply chain, enabling businesses to stay competitive in today’s fast-paced and ever-changing marketplace.

Warehouse Management System

Warehouse Management System (WMS): Enhancing Operational Efficiency

A Warehouse Management System (WMS) is a critical component of modern logistics and supply chain management. It is designed to optimize and streamline the daily operations of a warehouse, ensuring that everything from inventory tracking to order fulfillment is handled efficiently. A WMS oversees and streamlines daily warehouse operations, from receiving goods to shipping them out. By integrating a WMS into your business, you can reduce human error, improve order accuracy, and enhance overall productivity. Whether it’s through real-time tracking or automated workflows, a robust WMS offers the tools necessary to meet the growing demands of a dynamic market. Advanced WMS capabilities improve order accuracy, delivery speed, and overall operational efficiency.

1. What is a Warehouse Management System and What Does It Do?

A Basic Warehouse Management System offers essential functionalities to manage warehouse operations effectively. This type of system typically includes features such as inventory control, order management, and basic reporting. It is designed for small to medium-sized warehouses that need to improve accuracy and efficiency without the complexity of more advanced systems. By automating fundamental tasks, a basic WMS reduces manual errors and enhances productivity, making it a valuable tool for businesses looking to streamline their warehouse operations on a budget. Additionally, a WMS helps optimize labor resources by efficiently managing workforce allocation and reducing labor costs.

2. How Do I Know If My Business Needs the best Warehouse Management System?

Are you still unsure if you need the help of a warehouse management system to optimize your operations and improve your supply chain? Here are some of the signs that your business may need a WMS:

Inventory Management Challenges

If your business is struggling to manage inventory effectively, a WMS can help. A WMS provides real-time tracking of inventory levels, enabling businesses to keep track of stock levels, monitor product movement, and avoid stock outs or overstocking. With the help of a WMS, businesses can optimize inventory control and reduce the costs associated with excess inventory or lost sales.

Shipping Challenges

If your business is struggling with shipping logistics, you need a WMS that provides real-time tracking of shipments, enabling businesses to optimize their shipping processes, reduce the time required to process shipments, and avoid shipping errors. This way, you can streamline your shipping processes and provide better customer service.

Lack of Visibility and Traceability

The warehouse management system provides real-time visibility of inventory and order status across multiple warehouses, enabling businesses to track the movement of products, monitor performance metrics, and identify bottlenecks or areas for improvement. By using a WMS, businesses can optimize warehouse layouts, reduce the time required for inventory audits, and gain greater control over their warehouse operations.

Manual Processes and Paperwork

Does your business still rely on manual processes and paperwork to manage warehouse operations? If the answer is yes, it’s time to turn to a warehouse management system. A WMS provides automated data capture and processing capabilities, enabling businesses to reduce the time required to input data, minimize errors, and improve accuracy.

Increasing Order Volume and Complexity

If your business is experiencing an increase in order volume and complexity, a WMS might be the tool you need. A WMS provides scalability and flexibility to manage increasing volumes and complexity, enabling businesses to optimize their warehouse operations and adapt to changing customer demands. With the help of a WMS, businesses can handle more orders, reduce processing times, and enhance customer satisfaction.

Order Fulfillment Challenges

Are you struggling to fulfill orders accurately and efficiently? A Warehouse Management System provides real-time inventory tracking of orders, enabling businesses to optimize their order processing and reduce the time required to fulfill orders. With the help of a WMS, businesses can automate order picking and packing, ensuring that the right products are picked and shipped to the right customers. Advanced fulfillment capabilities in a WMS enable efficient management and execution of order fulfillment in modern, omnichannel supply chains.

But why stop there? By using the OIS Pro App, offered by Orders In Seconds, you can further enhance your order fulfillment process. The app provides simple order taking and tracking, inventory visibility, and reporting features that can help streamline your warehouse operations and improve customer satisfaction. With the OIS Pro App, your field sales reps gain visibility into inventory when placing orders, are able to track orders, and gain valuable customer insights to close deals faster, all from the convenience of their mobile device.

Overall, by combining the power of a WMS with the OIS Pro App, you can take your order fulfillment to the next level and position your business for success.

3. Understanding the Different Types of Warehouse Management Systems

There are different types of WMS available in the market, and each has its own advantages and disadvantages. WMS solutions can be deployed as cloud based wms systems or on premise solutions, each offering distinct advantages depending on business needs. Standalone systems offer specialized features and a high level of customization, but may require integration with other business systems. In contrast, WMS platforms provide advanced operational optimization, inventory tracking, and automation integration, making them comprehensive solutions for enhancing warehouse efficiency and supply chain coordination. Here is an overview of the four main types of WMS:

Standalone WMS

A standalone WMS is a software application installed on a company’s own servers or computers. This type of WMS is ideal for companies that want complete control over their warehouse management system and have the necessary infrastructure to support it. Standalone WMS usually require a large upfront investment in hardware and software, and ongoing maintenance costs.

Cloud-based WMS

A cloud-based WMS is a web-based application that is hosted on the vendor’s servers and accessed through the internet. This type of WMS is ideal for companies that want to minimize upfront costs, have limited IT resources, or require flexibility in terms of scalability and remote access. Cloud-based WMS typically offer pay-as-you-go pricing models, automatic updates, and 24/7 support.

Integrated WMS

An integrated WMS is a software application that is integrated with an enterprise resource planning (ERP) system or a transportation management system (TMS). This type of WMS is ideal for companies that want to streamline their operations by integrating warehouse management with other business processes such as inventory management, procurement, or other transportation management systems. Integrating WMS with order management systems (OMS) allows for unified order processing, customer communication, and multichannel sales coordination. Integrated WMS usually require more complex integrations and ongoing maintenance, but they offer the benefit of seamless data exchange and end-to-end visibility.

Supply Chain Modules

A Warehouse Management System enables small businesses to manage their warehouse operations, including shipping, picking, and receiving. However, it only covers a small part of the entire supply chain. In contrast, a Supply Chain Module (SCM) software helps manage everything from relationships with vendors to risk assessment. It focuses on automating inventory management, sourcing materials, and product cycles.

Integrating WMS with other applications is a great way to ensure cohesion between different parts of your business, and support holistic management of the whole supply chain. Combining WMS with SCM planning applications that also offer warehousing features is a common route for businesses. This allows for the exploration of the many benefits of SCM, while standalone solutions only cover warehousing.

If you choose to go this route, it’s important to minimize overlaps within your existing software. For example, you could potentially combine fleet management, inventory management, and warehouse management software solutions into a single SCM platform. Another way to avoid overlap is to choose an SCM solution that integrates with other business software like payroll and ERP systems.

4. Factors to Consider When Choosing the Best Warehouse Management System

After learning about the different types of WMS available, it’s important to consider how to choose the right one for your business. Some WMS solutions are designed specifically to meet the unique needs of certain industries or business sizes, ensuring a better fit for your operational requirements and budget. Reducing warehouse operating costs is a key factor when evaluating WMS options, as modern systems can improve efficiency and address labor shortages. There are several factors to consider when making this decision.

Business Requirements and Objectives

First, it’s crucial to consider your business requirements and objectives. What specific functionalities do you need from a WMS to improve your warehouse operations and overall supply chain management? Identifying your specific needs and objectives will help narrow down your options and ensure that the chosen system is a good fit for your business.

Consider the size of your warehouse, the number of SKUs, order volume, and other unique requirements.

Budget Considerations

Another important consideration is your budget. Different WMS solutions come at different price points, so it’s important to determine how much you can afford to invest in a WMS while still getting the features you need.

Understand the costs involved, including licensing fees, hardware, and ongoing maintenance.

Integration with Existing Systems

Lastly, WMS integration with existing systems is important. If you are already using other systems such as ERP, it’s essential to choose a WMS that can seamlessly integrate with these systems to avoid data inconsistencies and streamline your business processes.

Choosing the Right Technical Method for WMS-ERP Integration

There are three main technical options available for WMS integration: point-to-point integration, middleware integration, and Service-Oriented Architecture (SOA) integration.

Point-to-point integration involves directly connecting the WMS and ERP systems, allowing them to share data and communicate with each other. This method is suitable for smaller businesses with simpler requirements.

Middleware integration involves a third-party software application that acts as a mediator between the WMS and ERP systems. This method is more flexible and scalable and can handle complex requirements.

SOA integration is the most advanced method and uses a set of standaImplementing the best warehouse management system can be a challenging task, but the benefits are well worth the effort. A properly implemented WMS can improve efficiency, reduce errors, and increase customer satisfaction. To maximize efficiency, a successful WMS implementation should focus on optimizing material flows throughout the warehouse.

Here are some steps to follow when implementing a WMS:rds-based protocols and interfaces to integrate the WMS and ERP systems. This method is suitable for larger businesses with complex and diverse IT infrastructure.

Choosing the right WMS integration method depends on the business’s specific requirements and the IT infrastructure. Each method has its advantages and disadvantages, and businesses must carefully evaluate their options before making a decision.

Choosing the Right WMS Suppliers: A Key to Success

Selecting the right WMS suppliers is crucial for the success of your warehouse operations. Evaluating leading WMS vendors is an important step in selecting the right supplier for your business. The ideal supplier should offer a system that is customizable to fit your specific needs, scalable to grow with your business, and equipped with robust support services. Evaluating suppliers based on their experience, the comprehensiveness of their solutions, and their ability to integrate with your existing systems is essential. Moreover, a good supplier will not only provide a software solution but will also act as a partner in your business growth, offering insights and updates that keep you ahead of industry trends. Supply chain leaders are leveraging AI and machine learning to enhance warehouse and inventory management, driving digital transformation and operational efficiency.

5. The Implementation Process of a WMS and What to Expect

Implementing the best warehouse management system can be a challenging task, but the benefits are well worth the effort. A properly implemented WMS can improve efficiency, reduce errors, and increase customer satisfaction. Professional implementation services are essential for configuring, testing, and supporting the WMS throughout the deployment process. To maximize efficiency, a successful WMS implementation should focus on optimizing material flows throughout the warehouse.

Here are some steps to follow when implementing a WMS:

Conduct a thorough assessment of your business processes

Before implementing a WMS, you need to assess your existing warehouse processes. Identify areas where the current system is lacking and determine what features are required in a WMS to address those gaps.

Prepare for implementation

Once you have chosen the best warehouse management system that meets your business needs, you need to prepare for implementation. This involves determining the resources needed for the project, creating a project timeline, and defining the roles and responsibilities of everyone involved in the implementation.

Training staff

Proper training of your staff is crucial to the success of the WMS implementation. Your staff needs to understand how to use the new system and how it will improve their job performance. Training can be conducted in several ways, including classroom training, on-the-job training, and online training.

Monitoring performance and making adjustments

Once the WMS is implemented, you need to monitor its performance and make adjustments as needed. This involves collecting and analyzing data on warehouse operations, identifying areas for improvement, and making changes to the system or processes to optimize performance.

6

6. Best Practices in Warehouse Management: Key Strategies for Success

Implementing best practices in warehouse management is essential for maintaining a competitive edge in today’s fast-paced market. These practices not only improve warehouse operations but also contribute to more resilient and efficient supply chains. Key strategies include maintaining accurate inventory records, optimizing layout for efficient picking and packing, and implementing regular cycle counts. Additionally, leveraging technology, such as barcode scanning and WMS, can greatly enhance accuracy and speed. Training staff regularly and fostering a culture of continuous improvement are also crucial. By adhering to these best practices, warehouses can minimize errors, reduce costs, and improve overall customer satisfaction.

Continuous Process Improvement

Implementing the WMS is not a one-time solution. It is an ongoing process, and continuous process improvement is critical to achieve maximum benefits. To optimize your warehouse management process, you need to regularly evaluate your system and processes and make improvements where necessary.

Regular Maintenance

Regular maintenance of the WMS system is vital to ensure that the system operates at maximum efficiency. Regular maintenance should include software updates, hardware upgrades, and system testing.

Real-time Data Analysis

The warehouse management systems allow you to collect a vast amount of data about your warehouse operations. Analyzing this data in real-time can help you identify areas where you can make improvements to optimize your operations.

Monitor key performance indicators (KPIs)

Tracking KPIs such as inventory accuracy, order fulfillment rates, and cycle times can provide valuable insights into the health of your warehouse operations. Use this data to identify areas for improvement and track progress over time.

The Role of a Warehouse Management System

A WMS serves as the backbone of a warehouse, automating various tasks and processes. It enables efficient inventory management by providing real-time visibility into stock levels, locations, and expiration dates. Additionally, a WMS can automate order picking and packing processes, reducing errors and improving productivity.

Creating a Warehouse Management System

Developing a WMS involves several key steps:

- Needs Assessment: Identify the specific requirements and challenges of your warehouse operations.

- Software Selection: Choose a WMS solution that aligns with your needs and integrates seamlessly with your existing systems.

- Implementation: Install and configure the WMS software, ensuring it is tailored to your warehouse layout and processes.

- Data Migration: Transfer relevant data from your existing systems into the WMS.

- User Training: Provide comprehensive training to warehouse staff on how to use the WMS effectively.

Comprehensive Warehouse Management System Report

A Warehouse Management System report provides valuable insights into the performance and efficiency of your warehouse operations. These reports rely on accurate inventory data to provide actionable insights for warehouse managers. They can cover various aspects, including inventory levels, order accuracy, picking and packing efficiency, and overall productivity. By regularly reviewing these reports, warehouse managers can identify bottlenecks, make informed decisions, and implement changes that drive continuous improvement. A well-structured report serves as a roadmap for optimizing operations, reducing costs, and improving customer satisfaction.

Warehouse Management System Examples

Warehouse Management Systems (WMS) are essential tools in the logistics and supply chain industry. The best warehouse management systems are recognized for their robust security features, such as two-factor authentication and data encryption, to safeguard warehouse operations. They help manage and optimize warehouse operations, including inventory tracking, picking and packing, shipping, and receiving. Some popular examples of WMS include SAP Extended Warehouse Management (EWM), which provides real-time visibility and control over warehouse operations; Manhattan Associates WMS, known for its robust and scalable solutions that enhance productivity; and Blue Yonder (formerly JDA) Warehouse Management, which offers advanced AI and machine learning capabilities for improved decision-making. Other notable examples include Infor CloudSuite WMS, HighJump WMS, and Oracle Warehouse Management Cloud, each offering unique features tailored to specific industry needs. These systems are designed to streamline operations, reduce costs, and improve overall efficiency in warehouse management.

Warehouse Management Softwares

Warehouse management softwares are specialized tools designed to control and optimize the various functions within a warehouse. These softwares offer features like inventory management, order processing, picking and packing, shipping, and real-time data analytics. The primary goal of these softwares is to improve the efficiency and accuracy of warehouse operations. By leveraging these tools, businesses can reduce operational costs, enhance customer satisfaction through timely deliveries, and gain better insights into their supply chain performance.

WMS Software Tutorial

A WMS software tutorial provides comprehensive guidance on how to utilize Warehouse Management System software effectively. These tutorials typically cover the basics of system navigation, key functionalities such as inventory tracking, order management, and reporting tools. They may also include advanced topics like system integration, customization options, and troubleshooting common issues. By following a WMS software tutorial, users can gain the necessary skills to maximize the benefits of the software, ensuring that they can manage warehouse operations more efficiently and accurately.

Warehouse Management System

A Warehouse Management System (WMS) is a software solution designed to optimize and control warehouse operations. It provides tools for managing inventory, order fulfillment, shipping, receiving, and labor, offering a comprehensive view of warehouse activities. WMS can be tailored to meet the specific needs of various industries, from retail and manufacturing to healthcare and pharmaceuticals. By automating processes such as order picking and packing, barcode scanning, and inventory tracking, WMS helps reduce errors, improve accuracy, and enhance productivity. The system’s real-time capabilities allow for better decision-making and increased efficiency, making it an essential component for modern warehouses aiming to meet the demands of today’s fast-paced supply chain environment.

Warehouse Management System Description

A Warehouse Management System (WMS) is software designed to optimize and control daily warehouse activities. This system includes features such as inventory tracking, inbound and outbound order management, product location monitoring, and workforce management. An effective WMS description highlights the ability to automate manual processes, minimize human error, and provide real-time data for better decision-making. A WMS should also be capable of integrating with ERP and e-commerce systems to ensure seamless and transparent information flow between the warehouse and other business units.

Understanding Warehouse Management Systems

A Warehouse Management System (WMS) is a crucial tool for efficiently managing warehouse operations. It encompasses software and processes that allow organizations to control and administer warehouse operations from the time goods or materials enter a warehouse until they move out. These systems streamline inventory management, order fulfillment, and shipping processes, enhancing productivity and accuracy.

Warehouse Management Systems Examples

Warehouse Management Systems come in various forms, each offering distinct features to cater to different industry needs. For instance, Fishbowl Inventory is ideal for small to medium-sized businesses looking for affordable yet comprehensive inventory management solutions. Zoho Inventory offers a cloud-based platform that integrates with other Zoho applications for seamless business operations. Logiwa WMS is known for its user-friendly interface and strong e-commerce integrations, making it a popular choice for online retailers. Additionally, Softeon WMS provides advanced functionality for complex supply chain environments, while 3PL Central is specifically designed for third-party logistics providers. Each of these examples highlights the diverse capabilities of WMS solutions, from basic inventory control to sophisticated multi-channel fulfillment strategies.

What Makes the Best WMS Software: Key Features for Optimal Warehouse Management

The best Warehouse Management System (WMS) software offers a comprehensive suite of features that enable businesses to streamline and optimize their warehouse management processes. The best WMS software is characterized by key features such as real-time inventory tracking, barcode scanning, and automated data capture, ensuring accurate and up-to-date visibility into stock levels and locations. It also facilitates efficient order management, including order fulfillment, picking, packing, and shipping, minimizing errors and improving order accuracy.

The best WMS software offers robust reporting and analytics capabilities, providing insights into warehouse performance, productivity metrics, and inventory forecasting. It often integrates seamlessly with other business systems like Enterprise Resource Planning (ERP) software, allowing for smooth data exchange and comprehensive business process management. Additionally, the best WMS software should be user-friendly, with an intuitive interface and customizable workflows to match the unique requirements of the warehouse

It should also support scalability, allowing businesses to adapt and grow without outgrowing the software’s capabilities. By selecting the best WMS software, businesses can optimize their warehouse management, improve operational efficiency, reduce costs, and enhance customer satisfaction.

Streamlining Inventory Management Processes: The Backbone of Warehousing

Effective inventory management processes are the backbone of any successful warehouse operation. These processes include everything from receiving and storing goods to tracking inventory levels and fulfilling orders. Key practices such as accurate demand forecasting, real-time inventory tracking, and regular stock audits are essential for preventing stockouts and overstock situations. By optimizing these processes, businesses can ensure that they have the right products in the right quantities, reducing waste and improving order fulfillment times.

The Warehouse Floor: Maximizing Space and Efficiency

The warehouse floor is where the action happens, and its layout and organization can significantly impact operational efficiency. Optimizing material flows on the warehouse floor is essential for maximizing efficiency and resource utilization. A well-organized warehouse floor should allow for easy access to inventory, smooth traffic flow, and efficient use of space. Considerations such as the placement of high-turnover items, the design of picking routes, and the use of vertical space all contribute to a more productive environment. Investing in appropriate shelving, labeling systems, and material handling equipment can further enhance the efficiency of warehouse floor operations.

Warehouse Management System Workflow

A Warehouse Management System (WMS) workflow encompasses the comprehensive processes that streamline warehouse operations. A well-designed WMS workflow streamlines order fulfillment processes, from receiving to shipping, ensuring accuracy and efficiency at every step. From receiving and storing inventory to picking, packing, and shipping orders, a well-designed WMS workflow ensures accuracy, efficiency, and real-time inventory visibility. The workflow begins with the receipt of goods, where items are checked against purchase orders and then allocated to storage locations based on predefined rules. As orders come in, the WMS guides the picking process, optimizing paths and ensuring that the correct items are selected. Finally, the system supports the packing and shipping process, ensuring that orders are fulfilled accurately and promptly. A seamless WMS workflow reduces errors, minimizes delays, and enhances overall warehouse productivity.

Integrated Warehouse Management System

Effective Warehouse Management

Effective warehouse management is the cornerstone of any successful supply chain operation. It involves the strategic coordination of all activities within a warehouse, from inventory control to order fulfillment. Effective warehouse management is essential for optimizing supply chain operations and supporting business growth. Key components of effective warehouse management include the use of advanced technology, such as a WMS, to automate and streamline processes. Proper layout planning, staff training, and continuous process improvement are also critical. Effective management ensures that the warehouse operates smoothly, with minimal waste, reduced costs, and high levels of customer satisfaction. It helps in maintaining accurate inventory levels, reducing order processing times, and ensuring that goods are stored, handled, and shipped in the most efficient manner possible.

Warehouse System

Best Ecommerce Warehouse System

For ecommerce businesses, the best WMS should have robust order management capabilities, easy integration with ecommerce platforms, and support for multiple locations. ShipBob, Skubana, and Finale Inventory are some of the top WMS options that offer robust features for ecommerce businesses.

Best Warehouse Management System for Ecommerce

When selecting the best WMS for ecommerce, it’s essential to consider your business’s specific requirements. However, some of the critical features to look for include real-time inventory tracking, order management, and seamless integration with your ecommerce platform. ShipHero, Fishbowl Inventory, and Zoho Inventory are some of the best options available in the market.

Offline Stores and Warehouse Management Systems

Offline stores face unique challenges in warehouse management, including handling stock across multiple physical locations and the need to respond quickly to changing customer demands. A WMS can play a crucial role in helping offline stores manage their inventory more efficiently and ensure product availability on the shelves as needed. By using a WMS, offline stores can reduce storage costs, improve inventory accuracy, and provide a better shopping experience for customers. This system also enables stores to monitor sales performance across various locations, allowing them to make more strategic and informed stocking decisions.

Developing a Warehouse Management System

Developing a Warehouse Management System involves a deep understanding of warehouse workflows, inventory needs, and the latest technology. The first step in this development process is to analyze business requirements and design a system that can integrate with hardware such as barcode scanners and RFID. The system should also be capable of adapting to fluctuating inventory volumes and speeding up the processes of picking and shipping goods. Effective WMS development requires collaboration between IT and operational teams to ensure the system is implemented smoothly and delivers maximum benefits to the business.

The Best Warehouse Management Software

The best warehouse management software should provide an extensive range of features and functionalities that cater to different business needs. Some of the top WMS options available in the market include Fishbowl Inventory, Cin7, and DEAR Systems. These solutions offer comprehensive inventory management, order management, and labor management features.

In conclusion, selecting the best WMS for your business requires careful consideration of your functional requirements, business needs, and budget. With the right WMS in place, businesses can streamline their warehouse or distribution center operations, enhance inventory accuracy, and improve order fulfillment efficiency.

Warehouse Management Database

The warehouse management database is the core of an effective Warehouse Management System. This database stores all data related to inventory, such as product locations, stock quantities, and product information. A well-structured database must be organized and quickly accessible to ensure that warehouse operations run smoothly. The use of relational databases like MySQL, SQL Server, or Oracle Database is common in WMS applications because they can handle large volumes of data and support complex queries. Additionally, these databases should have strong security mechanisms to protect sensitive data from unauthorized access.

The Benefits of Integrating Your WMS with Inventory and Warehouse Management Software

Warehouse Management Systems (WMS) are essential tools for modern businesses to efficiently manage their inventory and warehouse operations. In this post, we’ll explore the benefits of integrating your WMS with inventory and warehouse management software, and discuss the advantages of using free warehouse software.

Automate Warehouse Inventory Management: The Future of Warehousing

Automating warehouse inventory management is rapidly becoming a necessity for businesses looking to stay competitive. Automation technologies, such as automated guided vehicles (AGVs), robotics, and AI-driven inventory tracking systems, can drastically reduce the time and labor required for routine tasks. Automated systems help in maintaining real-time inventory accuracy, optimizing storage space, and speeding up order fulfillment. By reducing reliance on manual processes, businesses can lower operational costs, reduce errors, and improve overall efficiency, paving the way for smarter, more responsive warehousing operations.

Understanding the Importance of a Warehouse Inventory Management System

A warehouse inventory management system is vital for maintaining accurate stock levels and ensuring smooth operations. This system helps in tracking inventory, managing orders, and predicting future stock needs. Learn about the different types of inventory management systems and how they can benefit your warehouse. Efficient inventory management is key to reducing costs and meeting customer demands.

Warehouse Management Procedure

Having a well-defined warehouse management procedure is essential for ensuring efficient and accurate warehouse operations. By integrating your WMS with warehouse management software, you can streamline your warehouse processes, reduce errors, and improve efficiency. A comprehensive warehouse management software can help you automate the process of receiving, storing, picking, and shipping products, as well as managing returns and exchanges.

Warehouse Management System Design

A well-designed Warehouse Management System (WMS) is pivotal for the smooth operation of any supply chain. An effective WMS should be designed specifically to address the unique operational requirements of the business, ensuring it meets the organization’s size, industry type, and workflow needs. It integrates various functions such as inventory tracking, order management, and shipping coordination into a cohesive system. Effective WMS design ensures efficient space utilization, reduces operational costs, and enhances customer satisfaction through accurate and timely order fulfillment. Key components include real-time data analytics, user-friendly interfaces, and scalable solutions to accommodate growing business needs. Incorporating advanced technologies like AI and IoT can further optimize processes by predicting inventory needs and monitoring equipment health, ultimately driving warehouse efficiency and productivity.

Inventory Management Software

Inventory management software can help you streamline your inventory processes and improve accuracy. By integrating your WMS with inventory management software, you can automate the process of tracking inventory levels, receiving new shipments, and managing stock levels. This can help you avoid stockouts, reduce carrying costs, and improve overall inventory management.

Warehouse Operating Systems

A warehouse operating system (WOS) is integral to optimizing warehouse management, streamlining processes, and ensuring efficiency. These systems encompass a variety of functionalities, such as inventory tracking, order fulfillment, and labor management. By integrating advanced warehouse operating systems with a comprehensive warehouse management system (WMS), businesses can enhance operational accuracy, reduce errors, and increase overall productivity. Implementing a robust WOS within a WMS framework allows for seamless coordination between different warehouse activities, leading to a more cohesive and efficient operation.

WMS Meaning

The term WMS stands for Warehouse Management System. It refers to software applications designed to support and optimize warehouse or distribution center management. WMS systems facilitate the daily operations of warehouses, including inventory management, order processing, and shipping coordination.

Bulk Fulfillment WMS

Bulk fulfillment WMS solutions are designed to handle large volume orders efficiently and accurately. These systems facilitate the processing of bulk orders, ensuring that inventory is managed effectively and that fulfillment timelines are met. By integrating a bulk fulfillment WMS, companies can streamline their operations, reduce processing times, and enhance customer satisfaction. This specialized aspect of a warehouse management system is essential for businesses dealing with high-volume shipments, providing the tools necessary for maintaining control and oversight over extensive inventory and order processes.

Commodities Warehouse Management System

A commodities warehouse management system (CWMS) focuses on the specific needs of warehouses handling raw materials and primary products. These systems are tailored to manage the unique challenges associated with commodities, such as varying storage conditions and regulatory requirements. By implementing a CWMS, businesses can ensure proper tracking, storage, and handling of commodities, leading to improved efficiency and compliance. This specialized WMS supports the intricate processes involved in commodities management, facilitating better control and optimization of warehouse operations.

Commodities WMS

Commodities WMS solutions are designed to address the specific demands of managing bulk goods and raw materials. These systems offer features such as real-time inventory tracking, quality control, and regulatory compliance, tailored to the unique requirements of commodities. By leveraging a commodities WMS, businesses can streamline their operations, reduce waste, and enhance the accuracy of their inventory management. This specialized system within the broader warehouse management system framework ensures that commodities are handled with the utmost efficiency and precision.

Low Cost Warehouse Management System

Low-cost warehouse management systems offer essential features for small to mid-sized businesses seeking to optimize their warehouse operations without significant financial investment. These systems provide core functionalities such as inventory tracking, order management, and reporting at an affordable price point. Implementing a low-cost WMS allows businesses to improve efficiency, reduce errors, and enhance customer service while maintaining budget constraints. Despite the lower cost, these systems can provide robust solutions that meet the operational needs of growing enterprises.

Retail Warehouse Management System

A retail warehouse management system is specifically designed to address the unique challenges of retail operations. This type of WMS manages high SKU counts, rapid inventory turnover, and seasonal fluctuations. It ensures accurate inventory tracking, efficient order fulfillment, and seamless integration with point-of-sale systems. Implementing a retail WMS enhances inventory visibility, reduces out-of-stock situations, and improves customer satisfaction by ensuring timely and accurate order delivery. For retailers, a specialized WMS is essential for maintaining competitive advantage and operational efficiency.

Comprehensive Warehouse Management System Software for Modern Warehouses

Warehouse management system software is essential for the modern warehouse, offering tools and features that streamline every aspect of warehouse operations. From real-time inventory tracking to automated order processing, discover how this software can improve efficiency and reduce errors. Implementing a robust warehouse management system software can lead to significant improvements in your overall operational performance.

Distribution Centers

Distribution centers play a vital role in the supply chain, serving as hubs for receiving, storing, and shipping products to various destinations. Implementing a warehouse management system in distribution centers enhances operational efficiency by automating key processes such as inventory management, order processing, and shipping. A WMS provides real-time visibility into distribution activities, enabling better decision-making and faster response times. Efficient management of distribution centers ensures timely delivery of products, improved customer satisfaction, and optimized supply chain performance.

Physical Inventory

Physical inventory management involves the manual counting and verification of stock within a warehouse. This process is crucial for maintaining inventory accuracy and ensuring that the recorded stock levels match the actual quantities. A warehouse management system supports physical inventory processes by providing tools for systematic counting, discrepancy reporting, and data reconciliation. Regular physical inventory checks, supported by a WMS, help businesses maintain accurate inventory records, reduce shrinkage, and improve overall operational efficiency.

Finally, you may also want to consider tools that can further optimize your warehouse operations. One such tool is the OIS Pro App, offered by Orders In Seconds. This app provides inventory visibility, simple order taking and tracking, and reporting features that can help streamline your warehouse operations and enhance your customer satisfaction. Schedule your free demo today!

Industry Applications and Use Cases of Warehouse Management Systems

Warehouse management systems (WMS) are essential across a diverse range of industries, each with unique operational requirements and challenges. In the world of third-party logistics (3PL) providers, WMS solutions enable seamless management of multiple clients’ inventory, ensuring accurate tracking, efficient order fulfillment, and optimal use of warehouse space. Retail distribution networks rely on warehouse management systems to maintain precise inventory levels, streamline replenishment, and support high-volume, fast-paced order processing, all of which contribute to improved customer satisfaction.

Ecommerce operations benefit from WMS by automating order picking, packing, and shipping, reducing errors and shipping times while providing real-time visibility into inventory levels. This leads to faster delivery and a better customer experience. In the consumer packaged goods (CPG) and manufacturing sectors, warehouse management systems play a critical role in managing raw materials, tracking work-in-progress, and coordinating the movement of goods through production and distribution centers. This ensures that inventory is always available where it’s needed, minimizing delays and optimizing production schedules.

Wholesale fulfillment operations leverage WMS to handle bulk orders efficiently, manage complex inventory assortments, and support B2B and B2C fulfillment models. Distribution centers, acting as key nodes in the supply chain, use WMS to coordinate inbound and outbound shipments, maximize warehouse space utilization, and maintain high service levels. Across all these industries, WMS solutions provide the tools needed to adapt to changing market demands, reduce operating costs, and deliver superior customer satisfaction.

Warehouse Management System (WMS):

This is a software application designed to support and optimize warehouse functionality and distribution center management. These systems enable centralized management of tasks such as tracking inventory levels and stock locations.

Warehouse Ordering System:

This is a component or a separate system that manages the process of placing orders within a warehouse. This can include:

- Internal Orders: Moving stock between different locations within the warehouse.

- Replenishment Orders: Ordering new stock from suppliers or other warehouses.

- Customer Orders: Processing and fulfilling orders from customers.

It is often a feature within a WMS, but can also be a stand alone system.

Warehouse Managment System:

This is simply a misspelling of “Warehouse Management System.”

Aplikasi Gudang dengan WMS (Indonesian):

This translates to “Warehouse Application with WMS.” It refers to any software application that includes or integrates with a Warehouse Management System, designed for use in a warehouse setting.

Aplikasi WMS Terbaik (Indonesian):

This translates to “Best WMS Application.” It refers to the top-rated or most effective Warehouse Management System applications available. The ‘best’ application will depend on the specific needs of the business.

HighJump WMS Demo:

HighJump is a well-known provider of Warehouse Management System software. A “HighJump WMS Demo” refers to a demonstration of their WMS software, typically used to showcase its features and capabilities to potential customers.

Warehouse Management System Course:

This refers to educational programs or training courses that teach individuals how to use and manage Warehouse Management Systems. These courses can cover topics such as:

- WMS functionality and features.

- Inventory management best practices.

- Warehouse operations and workflows.

- System configuration and implementation.

- Data analysis and reporting.

The Future of Warehouse Management Systems

The future of warehouse management systems is being shaped by rapid advancements in technology, promising even greater efficiency and responsiveness in warehouse operations. Artificial intelligence (AI) and machine learning are set to revolutionize inventory management by enabling predictive analytics for demand forecasting, automated replenishment, and dynamic optimization of inventory levels. These technologies help identify patterns, anticipate bottlenecks, and make data-driven decisions that enhance supply chain performance and customer satisfaction.

The integration of Internet of Things (IoT) devices within warehouse management systems is transforming real-time inventory tracking and warehouse condition monitoring. IoT sensors can provide instant updates on stock movements, environmental conditions, and equipment status, allowing for proactive management and reduced downtime. Cloud based WMS solutions are also gaining traction, offering businesses the flexibility to scale operations, access data from anywhere, and achieve significant cost savings by reducing the need for on-premise infrastructure.

Looking ahead, emerging technologies such as blockchain will bring greater transparency and security to inventory management and order fulfillment processes, while robotics and autonomous vehicles will automate routine tasks, further increasing operational efficiency. As these innovations become more accessible, warehouse management systems will continue to evolve, empowering businesses to respond swiftly to market changes, optimize resource usage, and deliver exceptional customer experiences. The future of WMS is one of continuous improvement, driven by smart technology and a relentless focus on efficiency and customer satisfaction.